Method for production of silicon carbide granularity sand special for recrystallized silicon carbide

A production method and silicon carbide technology are applied in the production field of special silicon carbide grain size sand for recrystallized silicon carbide products, which can solve the problems of low tap density, low high temperature flexural strength, low bulk density, etc. The effect of high density, high temperature flexural strength and high bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

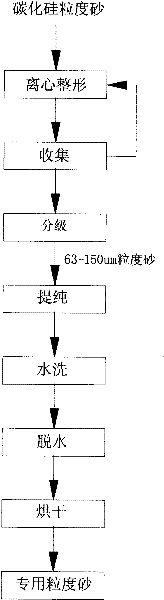

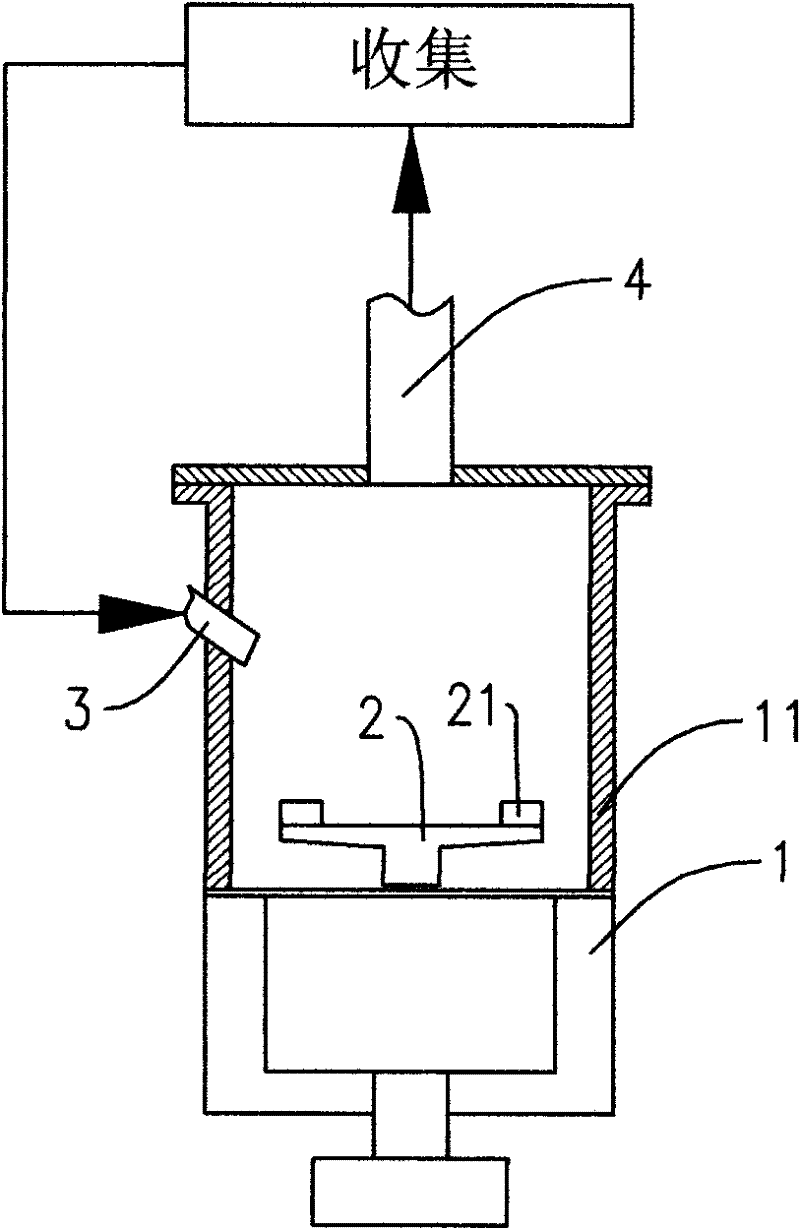

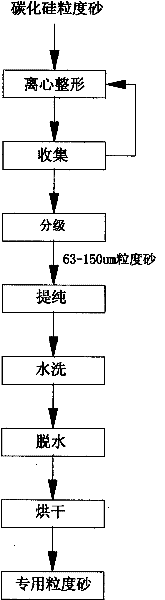

[0020] like figure 1 As shown, the production method of silicon carbide grain size sand special for recrystallized silicon carbide products includes steps:

[0021] Shaping The silicon carbide particle size sand with a median diameter of 100um is subjected to centrifugal circulation shaping for 5 hours.

[0022] Classification: Classify the grain size sand after shaping treatment, remove the fine powder and coarse powder, and take the silicon carbide grain size sand with a particle size of 80um-150um;

[0023] Purification The separated silicon carbide particle size sand is purified by acid washing and alkali washing respectively with a large amount of sulfuric acid and sodium hydroxide;

[0024] Washing with water, adjust the pH value to 5-6;

[0025] Dehydration, drying After dehydration, drying, drying temperature 120 ℃, time 18 hours, to obtain silicon carbide particle size sand specially used for recrystallized silicon carbide products with smooth surface, silicon carbi...

Embodiment 2

[0027] like figure 1 As shown, the production method of silicon carbide grain size sand special for recrystallized silicon carbide products includes steps:

[0028] Shaping The silicon carbide particle size sand with a median diameter of 80-100um will be shaped by the centrifugal circulation of the shaping machine for 8 hours.

[0029] Classification: Separating the grain size sand after shaping treatment, removing the fine powder and coarse powder, and taking the silicon carbide grain size sand with a particle size of 63um-150um and an average particle size of 100±5um;

[0030] Purification: Purify the separated silicon carbide particle size sand through pickling and alkali washing with excess sulfuric acid and sodium hydroxide respectively;

[0031] Washing with water, adjust the pH value to 5-6;

[0032] Dehydration and drying After dehydration, dry at 140°C for 12 hours to obtain silicon carbide particle size sand specially used for recrystallized silicon carbide product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com