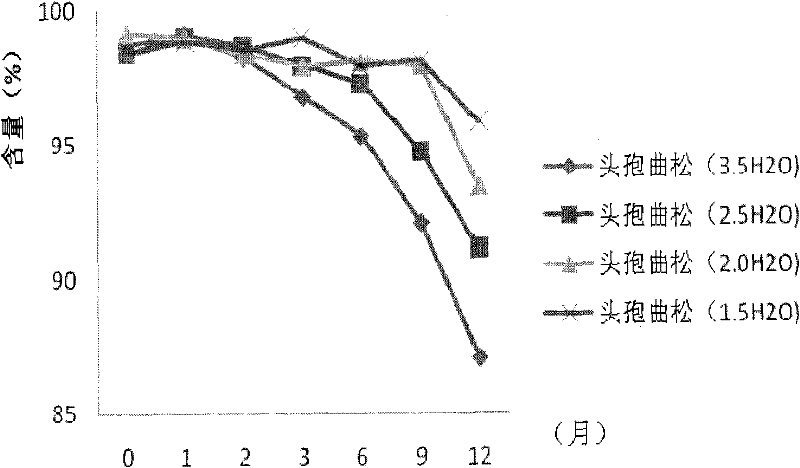

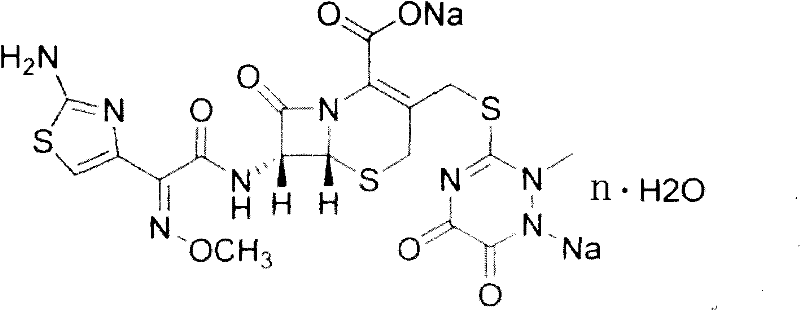

Low crystal-water ceftriaxone crystals and preparation method thereof

A technology of ceftriaxone sodium and low crystallization, which is applied in the field of ceftriaxone sodium crystals and its preparation, and can solve problems affecting the quality of ceftriaxone and affecting the safety and effectiveness of ceftriaxone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: One molecule contains the preparation method of 2.5 crystal water ceftriaxone sodium crystals

[0027] Add 160 mL of solvent water-absolute ethanol solution (volume ratio 1:3) into a jacketed crystallizer, add 45 g of ceftriaxone sodium salt, control the crystallization temperature at 15 ° C, add dropwise 300 mL of absolute ethanol, and add crystallization Seed or 0.2g, after growing the crystal for 20min, continue to add 400mL of absolute ethanol dropwise. Vacuum filter and wash twice with 300 mL of absolute ethanol. Dry under vacuum at 40° C. for 2 hours. Get 4 g of obtained ceftriaxone sodium crude crystals, add 4 g of absolute ethanol, and reflux for 4.5 hours. Dry under vacuum at 60°C for 2.5 hours to obtain ceftriaxone sodium crystals containing 2.5 crystal waters per molecule.

[0028] Wherein: ethanol can replace with formic acid, acetic acid, methyl alcohol, ethanol, n-propanol, isopropanol, n-butanol or isobutanol.

[0029] Among them: the dr...

Embodiment 2

[0030] Embodiment 2: One molecule contains the preparation method of 2.5 crystal water ceftriaxone sodium crystals

[0031] Add solvent water-acetone solution (volume ratio is 1:4) 120ml in the crystallizer with jacket, add 45g ceftriaxone sodium salt, control crystallization temperature to be 80 ℃, add dropwise absolute ethanol 300mL, add crystal seed or 0.2g, after growing the crystal for 20min, continue to add 400mL of formic acid dropwise. Vacuum filter and wash twice with 300 mL of acetone. Dry under vacuum at 100°C for 0.5 hours. Get 4 g of obtained ceftriaxone sodium crude crystals, add 20 g of n-butanol, and reflux for 0.5 hour. Dry under vacuum at 40°C for 0.5 hour to obtain ceftriaxone sodium crystals containing 2.5 crystal waters per molecule.

[0032] Among them: the drying temperature and time of the last step can be changed within a certain range, and the drying time can be shortened by about 0.5 hours for every 10°C increase in temperature.

Embodiment 3

[0033] Embodiment 3: One molecule contains the preparation method of 2.0 crystal water ceftriaxone sodium crystals

[0034] Add 160 mL of solvent water-chloroform solution (volume ratio 1:3) into a jacketed crystallizer, add 45 g of ceftriaxone sodium salt, control the crystallization temperature at 5 ° C, add dropwise 300 mL of absolute ethanol, and add crystal Seed or 0.2g, after growing the crystal for 20min, continue to add 400mL of the mixture of ethanol and isopropanol dropwise. Vacuum filter and wash twice with 300 mL acetic acid. Dry under vacuum at 10°C for 6 hours. Get 4 g of obtained ceftriaxone sodium crude crystals, add 4 g of n-butanol, and reflux for 5.5 hours. Drying under vacuum at 120° C. for 2 hours gave ceftriaxone sodium crystals containing 2.0 crystal water in one molecule.

[0035] Among them: the drying temperature and time of the last step can be changed within a certain range, and the drying time can be shortened by about 0.5 hours for every 10°C i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com