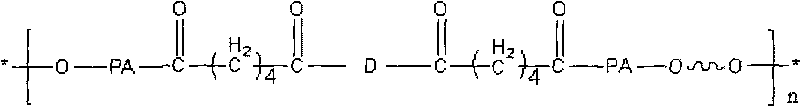

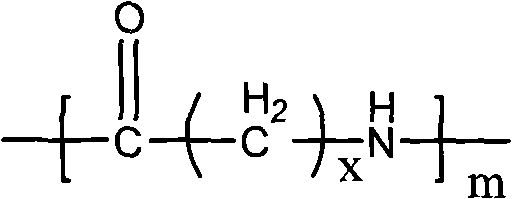

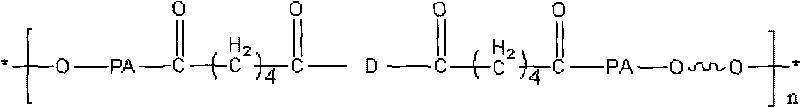

PA6 (polyamide 6) type thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer and elastomer technology, applied in the field of segment hard segment, can solve the problems of operator's health and surrounding environment, complicated solvent removal process, long reaction time, etc., and achieve good noise reduction effect, high toughness and high molecular weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Add 2000 parts of caprolactam, 60 parts of desalted water and 110 parts of adipic acid in the polymerization kettle, one part has a mass of 1 g, and after reacting for 4 hours at 3 bar pressure and 250 ° C, add 200 parts of 4'4- after cooling down to 230 ° C Diphenyl tetralkane diisocyanate (MDI), after continuing to react for 1 hour, add 280 parts of PTMG (2000) and 80 parts of isobutyl titanate, and continue to react for 4 hours at 230 ° C under stirring at a speed of 800 r / min. Then vacuumize to 50pa and continue the reaction for 1 hour. After boiling water extraction and drying, a light yellow polyamide thermoplastic elastomer with a soft segment content of 11% is obtained, with a tensile strength of 30.5Mpa, an elongation at break of 580%, and a Shore hardness of 70D.

Embodiment 2

[0045] Add 1000 parts of caprolactam, 40 parts of desalted water and 60 parts of adipic acid into the polymerization kettle, one part has a mass of 1 g, and after reacting for 3 hours at 5 bar pressure and 240 ° C, add 300 parts of 4'4-diphenyl tetra Alkane diisocyanate (MDI), after continuing to react for 1 hour, add 500 parts of PTMG (1000) and 80 parts of isobutyl zirconate, continue to react for 4 hours at 240 ° C, under stirring at a speed of 300 r / min, and then evacuate to Continue the reaction at 20 Pa for 1 hour, extract with boiling water and dry to obtain a light yellow polyamide thermoplastic elastomer with a soft segment content of 50%, a tensile strength of 12.5Mpa, an elongation at break of 350%, and a Shore hardness of 45D.

Embodiment 3

[0047] Add 1000 parts of caprolactam, 20 parts of desalted water and 30 parts of oxalic acid into the polymerization kettle, one part has a mass of 1g, react at 8bar pressure and 245°C for 5 hours, then add 100 parts of 1,5 naphthalene after cooling down to 225°C Diisocyanate (NDI), after continuing to react for 0.5 hours, add 100 parts of PEG (2000) and 50 parts of n-butyl zirconate, continue to react for 4 hours at 235 ° C, under stirring at a speed of 400 r / min, and then vacuumize to 500 Pa The reaction was continued for 0.5 hour, and after boiling water extraction and drying, a polyamide thermoplastic elastomer with a soft segment content of 50% was obtained, the tensile strength was 12.5 MPa, the elongation at break was 350%, and the Shore hardness was 42D.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com