Nanocable production method taking alumina as wrapping layer

A nano-cable and wrapping layer technology, which is applied in the direction of nano-structure manufacturing, cable/conductor manufacturing, anodic oxidation, etc., can solve the problems of cable core wire damage, uneven length, low output, etc., and achieve uniform length and scientific preparation method , good universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

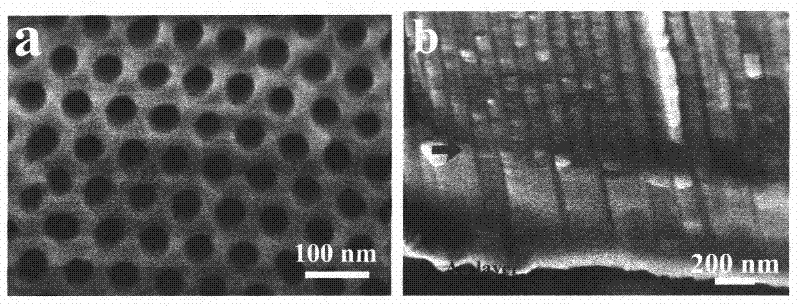

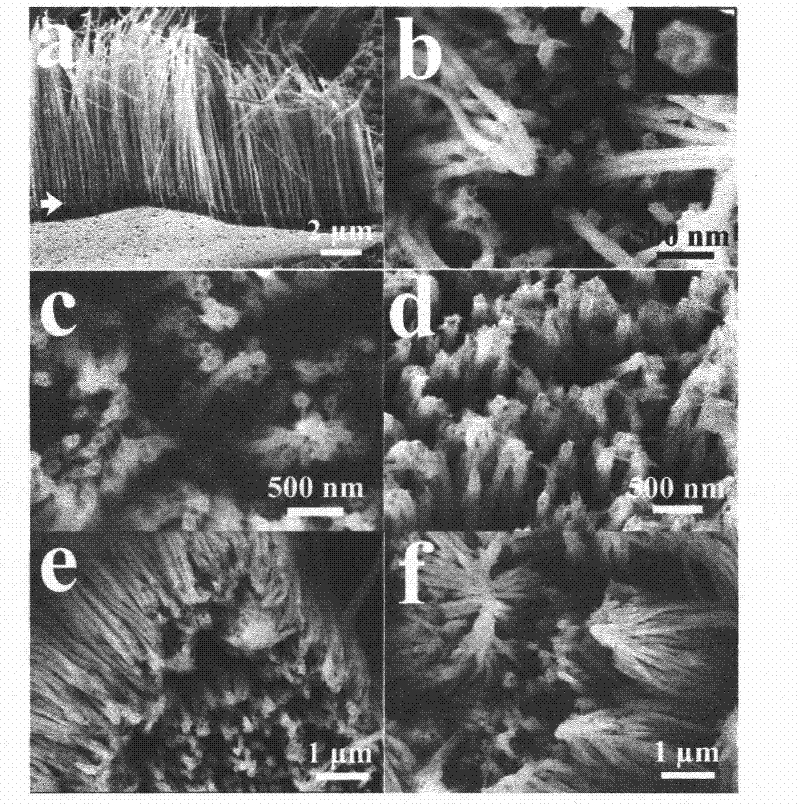

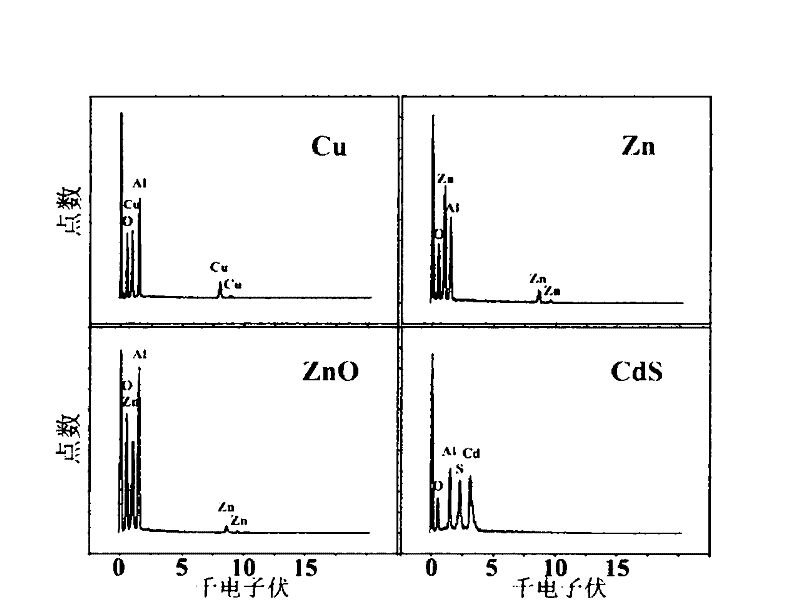

[0019] The specific steps of preparation are: step 1, first place the aluminum sheet in a sulfuric acid solution or oxalic acid solution with a concentration of 0.2M, and anodize it under DC voltage for 8 hours; wherein, the purity of the aluminum sheet is 99.9%, and place it in the sulfuric acid solution The DC voltage during anodic oxidation is 20V, and the DC voltage during anodic oxidation in oxalic acid solution is 28V. Then place it in a mixed solution of 4wt% phosphoric acid and 2wt% chromic acid at a temperature of 50° C. for 12 hours. Then, it was placed in the same acid solution and anodized at the same DC voltage for 10 hours, and then the DC voltage was increased by 1.73 times instantaneously, and anodized for 10 minutes. Afterwards, the unoxidized aluminum on the back is removed with a supersaturated tin tetrachloride solution, and then the aluminum oxide barrier layer at the bottom of the hole is etched away with a 3wt% phosphoric acid solution to obtain an appro...

Embodiment 2

[0023] The specific steps of preparation are: step 1, first place the aluminum sheet in a sulfuric acid solution or oxalic acid solution with a concentration of 0.25M, and anodize it under DC voltage for 7 hours; wherein, the purity of the aluminum sheet is 99.99%, and place it in the sulfuric acid solution The DC voltage during anodic oxidation is 22V, and the DC voltage during anodic oxidation in oxalic acid solution is 33V. Then place it in a mixed solution of 5wt% phosphoric acid and 1.9wt% chromic acid at a temperature of 55°C for 11 hours. Then, it was placed in the same acid solution and anodized at the same DC voltage for 9 hours, and then the DC voltage was increased by 2 times instantaneously, and anodized for 11 minutes. Afterwards, the unoxidized aluminum on the back is removed with a supersaturated tin tetrachloride solution, and then the aluminum oxide barrier layer at the bottom of the hole is etched away with a 4wt% phosphoric acid solution to obtain an approxi...

Embodiment 3

[0027] The specific steps of preparation are: step 1, first place the aluminum sheet in a sulfuric acid solution or oxalic acid solution with a concentration of 0.3M, and anodize it under DC voltage for 6 hours; wherein, the purity of the aluminum sheet is 99.9%, and place it in the sulfuric acid solution The DC voltage during anodic oxidation is 24V, and the DC voltage during anodic oxidation in oxalic acid solution is 39V. Then place it in a mixed solution of 6wt% phosphoric acid and 1.8wt% chromic acid at a temperature of 60° C. and soak for 10 hours. Next, it was placed in the same acid solution for anodization at the same DC voltage for 8 hours, and then the DC voltage was increased by 1.73 times instantaneously, and the anodization was continued for 13 minutes. After that, remove the unoxidized aluminum on the back side with supersaturated tin tetrachloride solution, and then use 5wt% phosphoric acid solution to etch the aluminum oxide barrier layer at the bottom of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com