Direct alcohol type fuel cell system

A fuel cell system and alcohol technology, which is applied in the field of direct alcohol fuel cell systems, can solve the problems of increasing the total cost of the fuel cell system, reducing the net output power of the system, and high requirements for design and preparation, so as to reduce the failure rate. and system energy loss, increase net output power, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

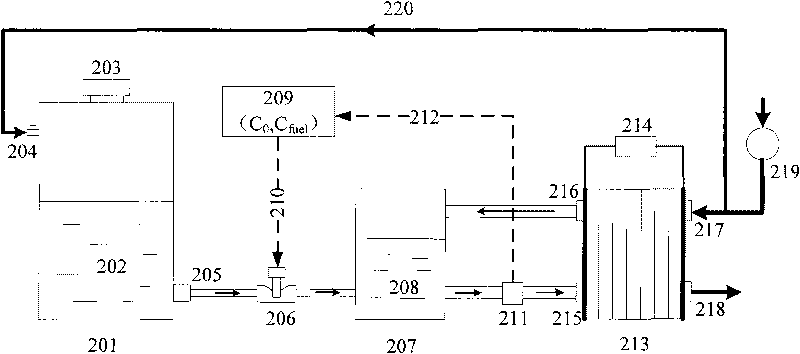

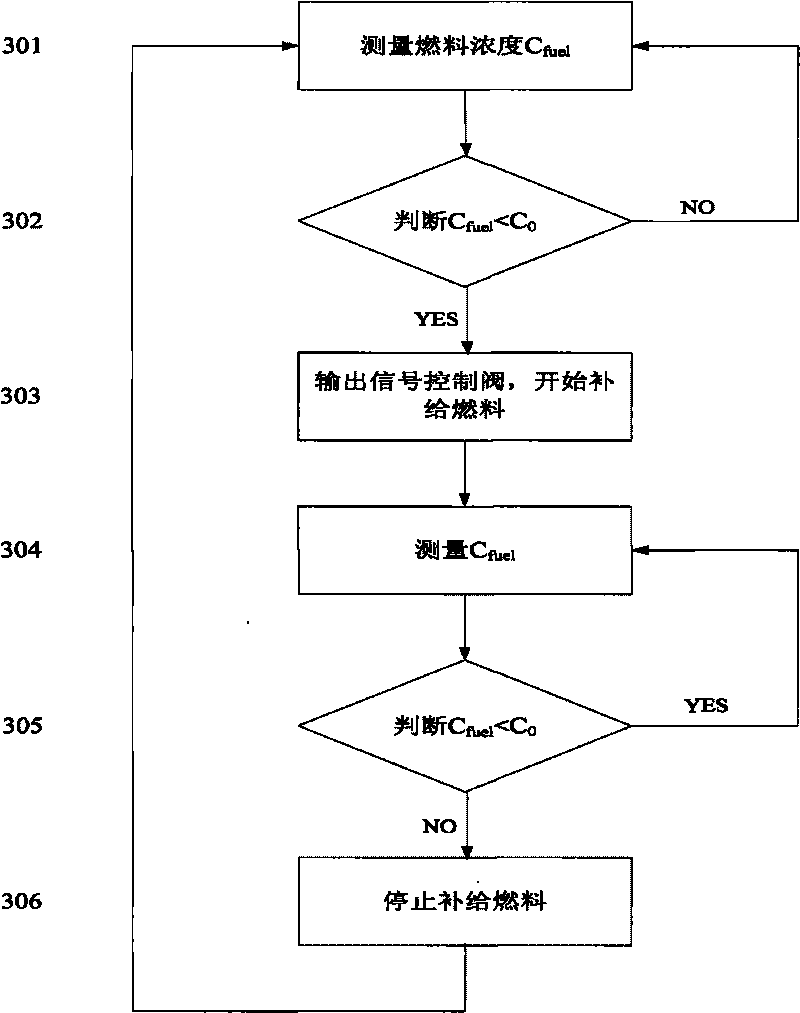

[0042] figure 1 It is a process diagram for implementing the direct alcohol fuel cell system. In this embodiment, the feedback control method is used to control the supply of high-concentration fuel, and the valve used by the controller to control the supply of fuel is a continuous regulating valve. figure 1 Middle 201 is a fuel tank, which has various shapes, such as square, cylindrical, elliptical cylindrical, spherical, etc., and is obtained by injection molding or other methods of fuel corrosion-resistant materials such as plastics, metals, and alloys. 202 is the high-concentration fuel in the fuel tank, which can be liquid organic hydrocarbons such as pure methanol and ethanol. 203 is the upper opening of the fuel tank, fuel can be added from here, and devices such as plugs or caps can be used to seal to prevent gas leakage in the tank. The valve 204 is connected with the gas path of the cathode oxidant feed subsystem through a pipeline, and is used for charging the fue...

Embodiment 2

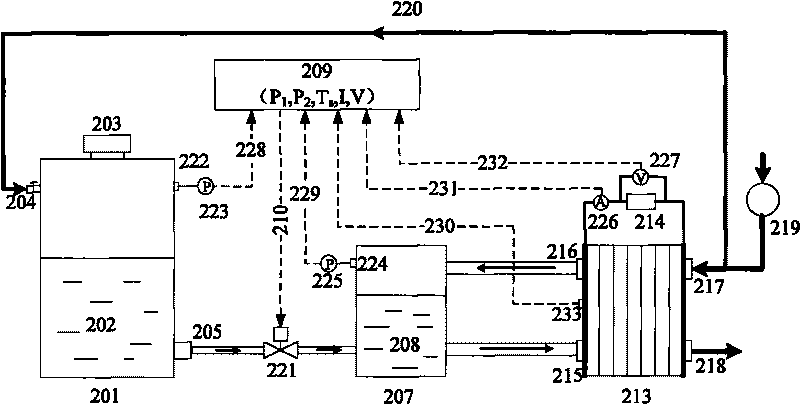

[0049] image 3 It is another process diagram for implementing the direct alcohol fuel cell system. The difference from Embodiment 1 is that the controller 209 of this embodiment adopts the active control method to control fuel replenishment, and has a built-in control program capable of judgment and calculation, and the valve used to control the replenishment of high-concentration fuel is a digital on-off valve. Solenoid valve 221. image 3 , the gas pressure P in the fuel tank 201 1 It is measured by a pressure transmitter 223 connected to the interface 222 , and the pressure signal 223 can convert the pressure signal into a voltage signal 228 and input it to the controller 209 . Similarly, the gas pressure P in the anode fuel mixing subsystem 207 2 It can be measured by a pressure transmitter 225 connected to the interface 224 , and the pressure signal can be converted into an electrical signal 229 by the 225 and input to the 209 . In addition, a temperature sensor 233,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com