Preparation of mineral particles in a supercritical CO2 medium

A kind of inorganic particles, supercritical technology, applied in the process of supercritical conditions, inorganic chemistry, liquid into beads and granulation, etc., can solve the problems of high internal porosity, reduce process costs, reduce liquid and The effect of gas effluent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] ZrO 2 Synthesis of particles (unsintered)

[0098] In this example, ZrO was synthesized by the method of the present invention from a medium (F1) prepared under the following conditions 2 Granules:

[0099] - 1.5 g zirconium ethoxide (i.e. 5.5 x 10 -3 mol) reflux heated to 50 ° C for 3 hours,

[0100] -Join 5.5×10 -3 mol formic acid, the medium was then heated to reflux again to 50°C for 30 minutes,

[0101] -Then add 0.54g HNO to the obtained medium 3 70% aqueous solution.

[0102] The medium (F1) obtained after the above-mentioned steps is in liquid form and has a milky appearance.

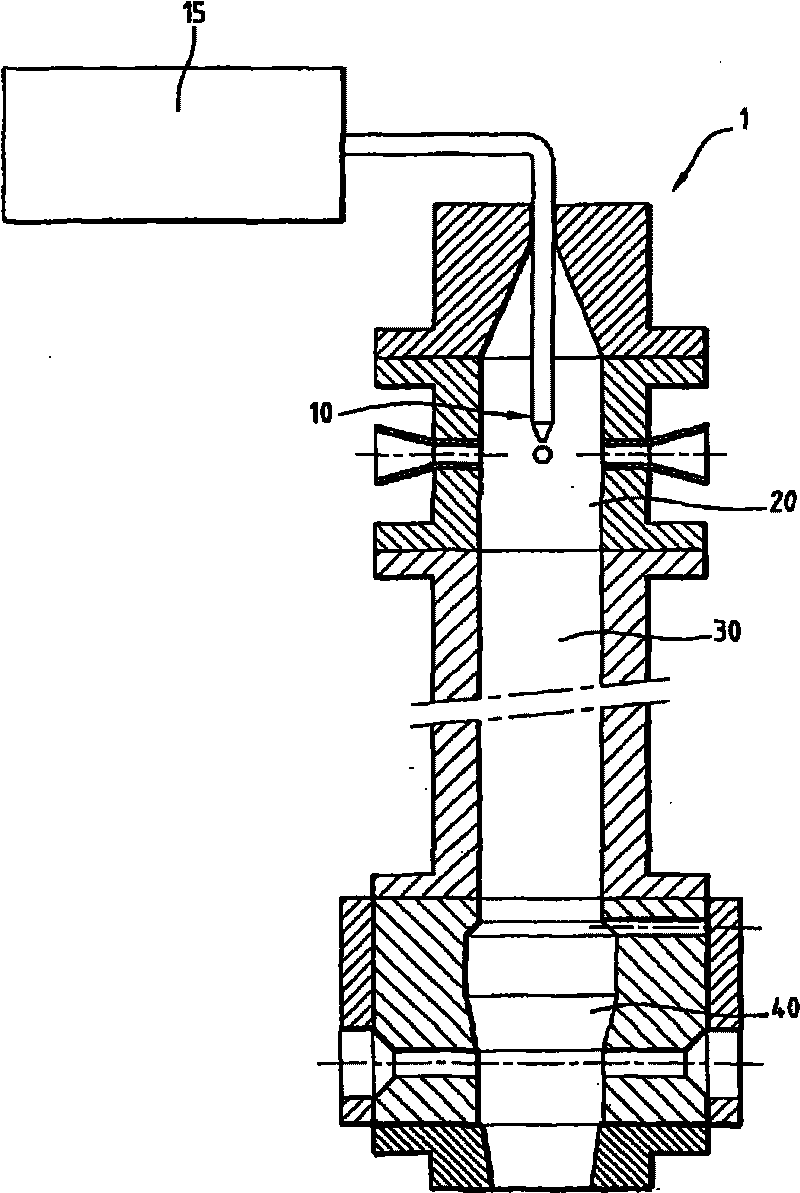

[0103] The medium (F1) was placed in a container 15 and injected through the injection nozzle 10 at a rate of 20 ml / hour at a pulse rate of two drops per second (pulse valve) under the following conditions:

[0104] - temperature in the injection chamber 20: 200°C;

[0105] - temperature in the recovery chamber 40: 315 °C;

[0106] - an increasing temperature gradient between th...

Embodiment 2

[0111] ZrO introduced into preformed SiC particles 2 Synthesis of particles

[0112] In this example, particles were synthesized by the method of the invention from a medium (F2) prepared under the following conditions:

[0113] -While stirring will contain 3g of zirconium ethoxide (i.e. 11×10 -3 mol), 20g ethanol and 0.54g70% HNO 3 The mixture of aqueous solutions is heated to reflux to 50° C. for 4 hours, thereby dissolving the zirconium ethoxide in the medium;

[0114] -The medium is then allowed to cool to ambient temperature (25° C.) and 4 g of water and 5.5×10 -3 mol formic acid, the medium was stirred for 1 hour;

[0115] - Add 0.019 g of SiC crystals with an average diameter of 30 nm to the medium.

[0116] The medium (F2) obtained after the above-mentioned steps is in the form of a polymer gel whose fluid properties depend on the time and speed of stirring (thixotropic effect).

[0117] This medium (F2) was placed in a container 15 and injected through the injec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com