Yeast extract with high glutamic acid content and preparation method thereof

A technology of yeast extract and yeast milk, which is applied in the field of high-glutamic acid yeast extract and its preparation, can solve the problem of low glutamic acid content, achieve delicious taste, meet large-scale commercial production, and strengthen food freshness. Powerful effect of taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] 2. Preparation of Yeast Extract

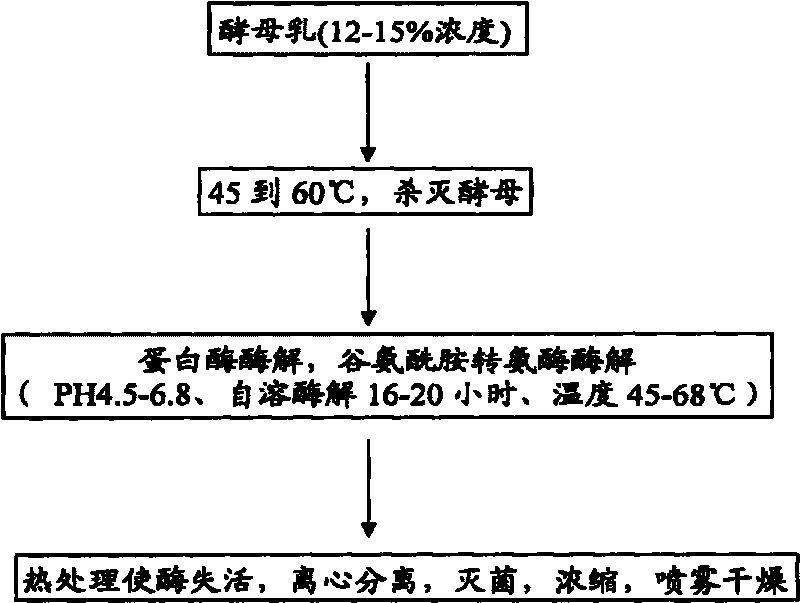

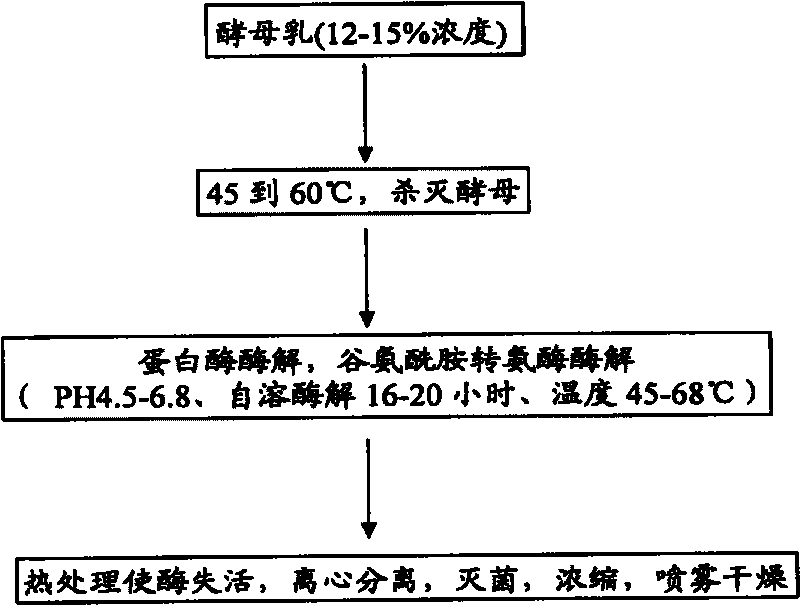

[0030] The preparation method of yeast extract provided according to the present invention may further comprise the steps:

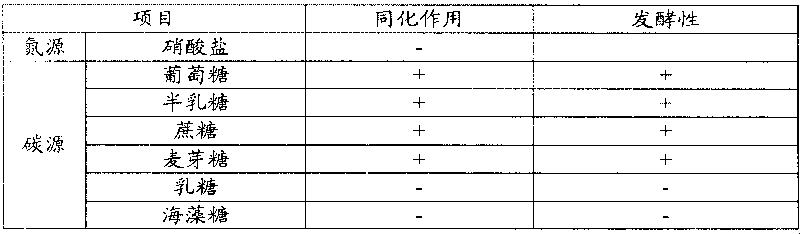

[0031] A) Cultivate a yeast strain in a medium containing ammonia water, the preservation number is CCTCCNO: M 205130, and centrifuge the culture obtained above, and collect the precipitate (or heavy phase) after centrifugation to obtain yeast milk;

[0032] B) Adjust the pH value of the yeast milk to an acidic level (pH4.5-6.8), and then heat it to 45°C to 60°C to kill the yeast. Control the temperature at 45-60°C, because if the temperature is lower than 45°C, harmful microorganisms such as gas-producing bacteria will easily grow, resulting in deterioration of raw materials; if the temperature is higher than 60°C, the protein will be severely denatured and difficult to degrade;

[0033] C) Autolytic enzymolysis, adding protease enzymolysis and transglutaminase to the above yeast milk, and performing enzymolysis...

example 1

[0052] Use the yeast milk of yeast CCTCC M 205130 fermented in molasses enriched with nitrogen source as the raw material, dilute it with water to a dry matter content of 13%-15%, at a temperature of 48°C-52°C, by adding hydrochloric acid or sulfuric acid Adjust its pH to 5.5 and maintain it for 10 hours, then raise the temperature to 55°C, add papain, its content accounts for 1.5‰ of the yeast mass, its content of glutamine transaminase accounts for 1.5‰ of the yeast mass, and adjust the pH value to 6.0- 6.5, act for 4 hours, then heat up to 60°C, act for 4 hours, then keep warm at 65°C for 1 hour to inactivate the enzyme preparation, then perform centrifugation in a centrifuge, sterilize, and then concentrate in a concentration equipment 1. Use a spray drying tower to carry out spray drying, and finally prepare a product. A 2700 type biochemical analyzer was used to test the glutamic acid content of the obtained product, and the glutamic acid content of the final product was...

example 2

[0054] The same process as Example 1, except that the amount of protease added is 2‰, the amount of transglutaminase added is 1‰, the pH value is 6.0-6.5, and the temperature is 55°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com