Method for removing boron and phosphorus during production of polysilicon with improved siemens process

A Siemens method and polysilicon technology, applied in the field of polysilicon production, can solve problems such as unsatisfactory impurity removal, mass transfer, and insufficient reaction, and achieve the effects of reducing operating risks, improving distillation and separation effects, and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 Adopt the method of the present invention to produce trichlorosilane

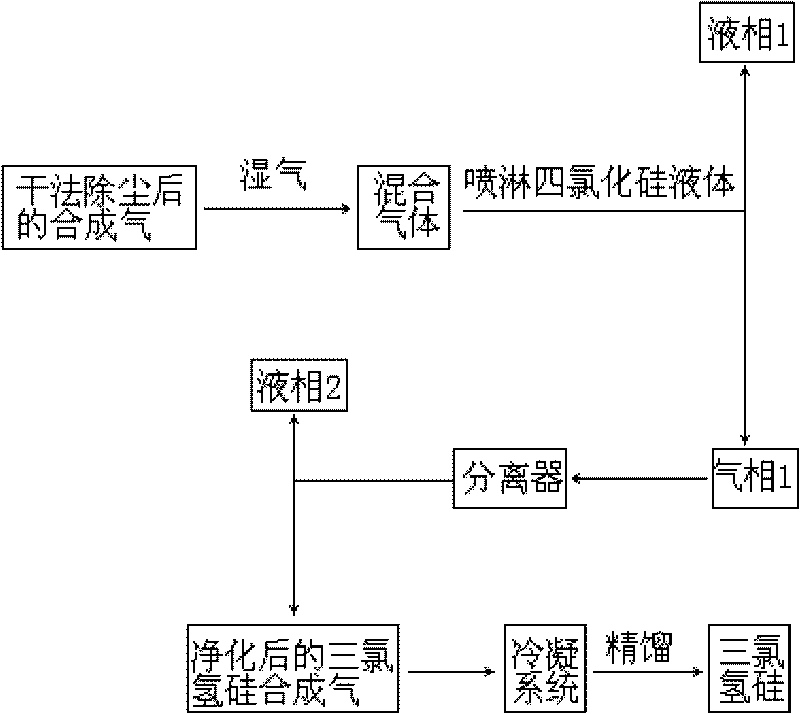

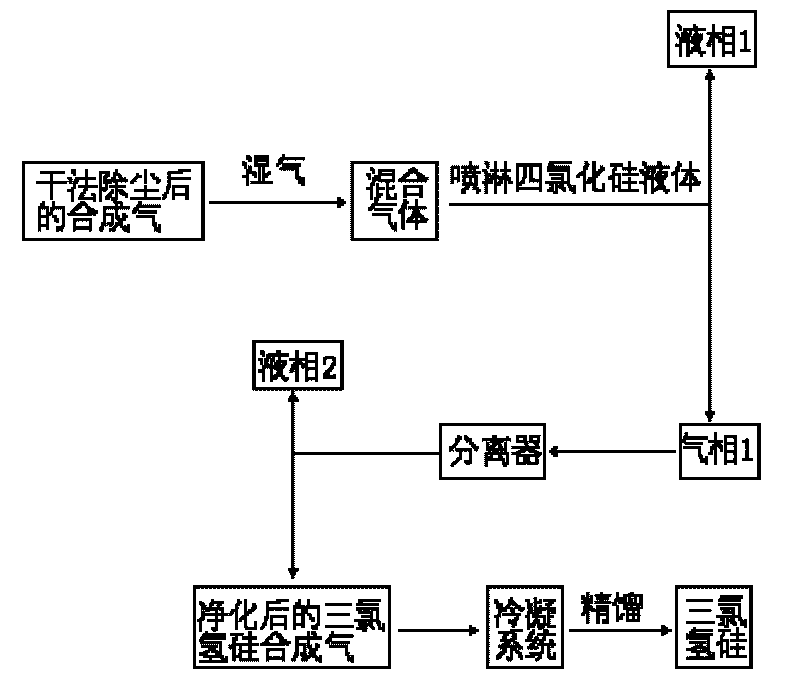

[0027] Process flow chart such as figure 2 As shown, the syngas after dry dedusting (flow rate 200NM 3 / h, impurity content: boron 700ppb, phosphorus 500ppb), moisture (temperature: 32 ℃, humidity: 15% RH, flow: 25NM 3 / h) into the reactor respectively to react and spray silicon tetrachloride (flow rate: 1M 3 / h, temperature: 25°C), the impurity-containing silicon tetrachloride and the synthesis gas with high boilers collected from the reactor are first passed into the bubbler. The synthesis gas with high boilers enters the separator and is washed by silicon tetrachloride (temperature: 25°C) in the separator. The impurity content in the purified synthesis gas is: boron 400ppb, phosphorus 300ppb, purified The synthesis gas enters the condensation recovery system and undergoes cryogenic cooling (temperature: -50°C) to obtain silicon tetrachloride condensate. The silicon tetrachloride ...

Embodiment 2

[0029] Embodiment 2 Adopt the method of the present invention to produce trichlorosilane

[0030] Process flow chart such as figure 2 As shown, the syngas after dry dedusting (flow rate 100NM 3 / h, impurity content: boron 700ppb, phosphorus 500ppb), humidity (temperature: 25°C, humidity: 8% RH, flow: 15NM 3 / h) into the reactor to react and spray silicon tetrachloride (flow rate: 0.5M 3 / h, temperature: 25°C), the impurity-containing silicon tetrachloride and the synthesis gas with high boilers collected from the reactor are first passed into the bubbler. The synthesis gas with high boilers enters the separator and is washed by silicon tetrachloride (temperature: 25°C) in the separator. The impurity content in the purified synthesis gas is: boron 380ppb, phosphorus 200ppb, purified The synthesis gas enters the condensation recovery system and undergoes cryogenic cooling (temperature: -50°C) to obtain silicon tetrachloride condensate. The silicon tetrachloride condensate i...

Embodiment 3

[0032] Embodiment 3 Adopt the method of the present invention to produce trichlorosilane

[0033] Process flow chart such as figure 2 As shown, the syngas after dry dedusting (flow rate 230NM 3 / h, impurity content: boron 700ppb, phosphorus 500ppb), humidity (temperature: 34 ℃, humidity: 20% RH, flow: 25NM 3 / h) respectively pass into the reactor to react and spray silicon tetrachloride (flow rate: 1.2M 3 / h, temperature: 25°C), the impurity-containing silicon tetrachloride and the synthesis gas with high boilers collected from the reactor are first passed into the bubbler. The synthesis gas with high boilers enters the separator and is washed by silicon tetrachloride (temperature: 25°C) in the separator. The impurity content in the purified synthesis gas is: boron 450ppb, phosphorus 310ppb, purified The synthesis gas enters the condensation recovery system and undergoes cryogenic cooling (temperature: -50°C) to obtain silicon tetrachloride condensate. The silicon tetrachl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com