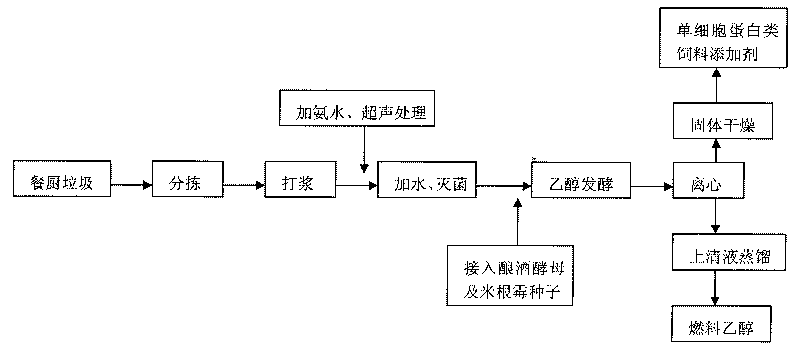

Method of co-fermenting kitchen waste with mixed bacteria for producing fuel ethanol

A technology for kitchen waste and fuel ethanol, which is applied in the directions of microorganism-based methods, biofuels, biochemical equipment and methods, etc., can solve the problems of raw materials that cannot be hydrolyzed, lack of glucose, etc., achieves high utilization, and simplifies production processes and equipment. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Isolation and identification of bacterial species

[0021] A number of distiller's grains and commercially available koji samples were collected, and different types of distiller's grains and koji medicine samples were enriched and cultivated. After dilution, the colonies isolated by the plate dilution method were inoculated into inclined test tubes, and the preliminary morphological identification was carried out.

[0022] Rinse the surface of the fungal slant test tube culture with normal saline, and perform gradient dilution on the obtained cell suspension. Select a suitable gradient dilution solution and apply it to the surface of the cellulose-Congo red medium and the starch-inorganic salt medium for primary screening. The strains that can produce both cellulase and amylase obtained from the primary screening were re-screened with the enzyme-producing medium, and a strain with both cellulase activity and amylase activity was screened out.

[0023] Streak inoculate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com