Anti-rust additive, and preparation method and application thereof

A technology of anti-rust additives and addition amount, applied in the field of anti-rust additives, can solve the problems of low solubility of oil-capable anti-rust additives, no anti-rust effect, sensitivity to electrolytes, etc., and achieve good anti-rust effect and good wetting. , the effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

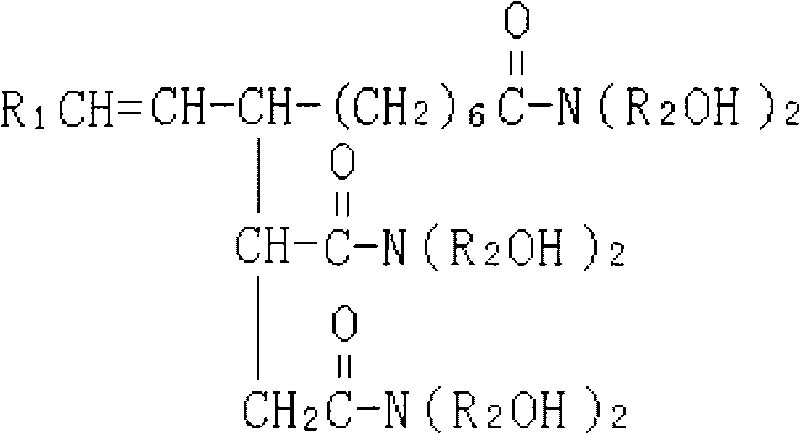

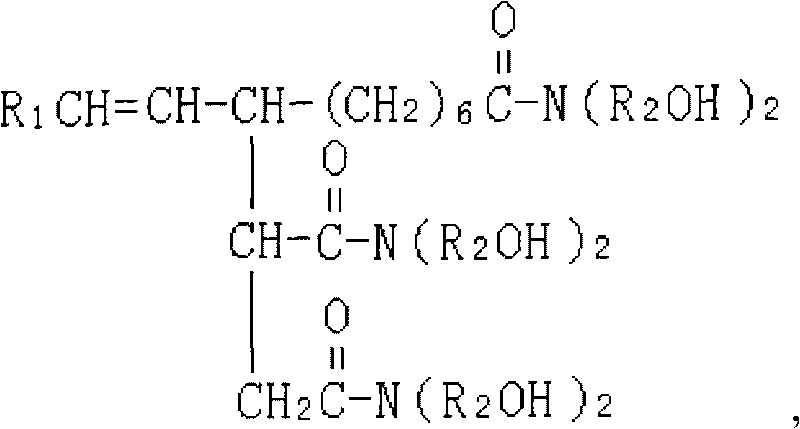

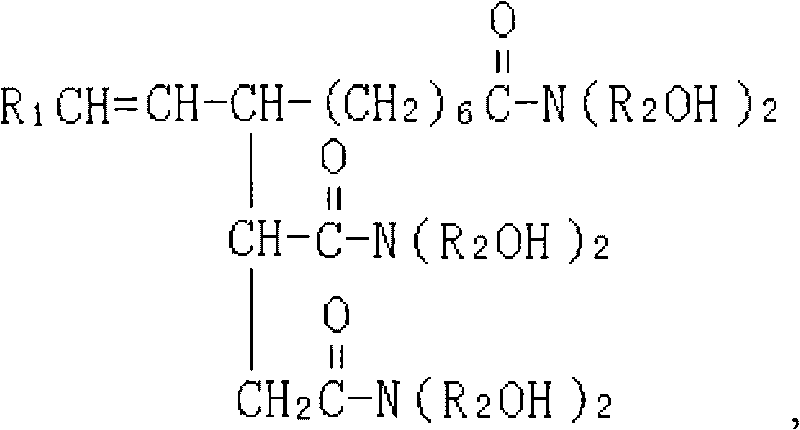

Method used

Image

Examples

Embodiment 1

[0023] 1) In terms of weight ratio, first add 78.8 kg of oleic acid CH to the heated and stirred stainless steel reactor when it is preheated to 80°C 3 (CH 2 ) 7 CH=CH(CH 2 ) 7 COOH, heat and stir, add 27.35 kg of maleic anhydride and 0.1 kg of phosphoric acid solution with a concentration of 85% by mass at 140°C, then continue to heat and stir, and continue to react at 175°C for 4 hours, and the acid value is ≤ 15%;

[0024] 2) After the reaction, stop heating, cool down naturally, when the temperature drops to 130°C, add 93.8 kg of diethanolamine HN(CH 2 CH 2 Oh) 2 With 0.4 kg of potassium hydroxide, after the addition of the feed, vacuumize the reaction, the pressure is 10.1325KPa, vacuumize to remove the water generated in the reaction process, control the reaction temperature to be 145 ° C, continue the reaction for 3.5 hours, and the amine value is 16.32;

[0025] 3) After the reaction, the temperature was naturally lowered to 60°C to obtain a brownish-yellow oil ...

Embodiment 2

[0033] 1) In terms of weight ratio, first add 158.1 kg of oleic acid CH to the heated and stirred stainless steel reactor when it is preheated to 80°C 3 (CH 2 ) 7 CH=CH(CH 2 ) 7 COOH, heat and stir, add 55 kg of maleic anhydride and 0.3 kg of 85% phosphoric acid solution at 140 ° C, then continue heating and stirring, and continue to react at 175 ° C for 4 hours, the acid value is ≤ 15 %;

[0034] 2) After the reaction, stop heating, cool down naturally, and when the temperature drops to 130°C, add 188 kg of diethanolamine HN(CH 2 CH 2 Oh) 2 With 0.6 kg of potassium hydroxide, after the addition of the feed, vacuumize the reaction, the pressure is 10.1325KPa, vacuumize to remove the water generated in the reaction process, control the reaction temperature to be 145 ° C, continue the reaction for 3.5 hours, and the amine value is 16.32;

[0035] 3) After the reaction, the temperature was naturally lowered to 60°C to obtain a brownish-yellow oil with a solid content ≥ 99%...

Embodiment 3

[0037] 1) In terms of weight ratio, first add 236 kg of oleic acid CH to the heated and stirred stainless steel reactor when it is preheated to 80°C 3 (CH 2 ) 7 CH=CH(CH 2 ) 7 COOH, heat and stir, add 82 kg of maleic anhydride and 0.6 kg of 85% phosphoric acid solution at 140 ° C, then continue heating and stirring, and continue to react at 175 ° C for 4 hours, the acid value is ≤ 15 %;

[0038] 2) After the reaction, stop heating, cool down naturally, when the temperature drops to 130°C, add 283 kg of diethanolamine HN(CH 2 CH 2 Oh) 2 With 0.8 kg of potassium hydroxide, after the addition of the feed, vacuumize the reaction, the pressure is 10.1325KPa, vacuumize to remove the water generated in the reaction process, control the reaction temperature to 145 ° C, continue the reaction for 3.5 hours, and the amine value is 16.32;

[0039]3) After the reaction, the temperature was naturally lowered to 60°C to obtain a brownish-yellow oil with a solid content ≥ 99%; firstly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com