Integrated system for controlling production processes of coiling, connecting and wrapping cigarettes

A production process control and integrated system technology, applied in electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problem of high error rate of production brand scheduling information transmission, increased cost and construction difficulty, inconvenient for worker scheduling management, etc. problems, to achieve the effect of improving production coordination ability, optimizing information transmission, and improving automation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

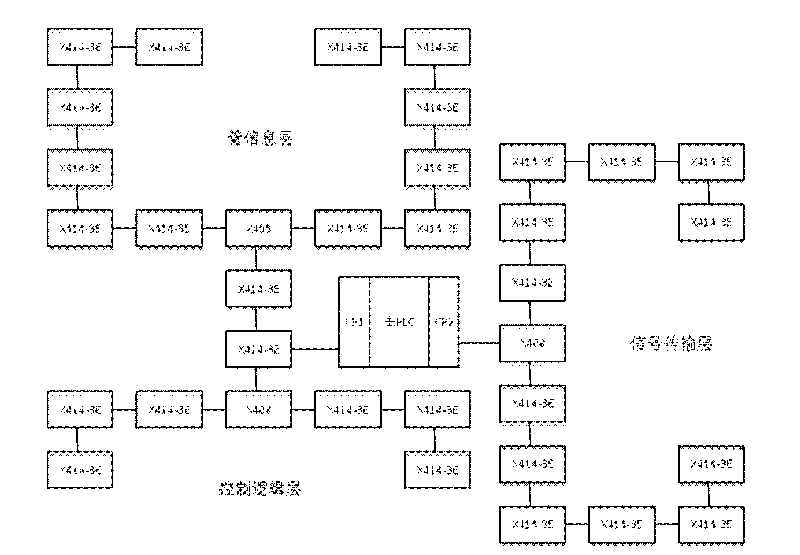

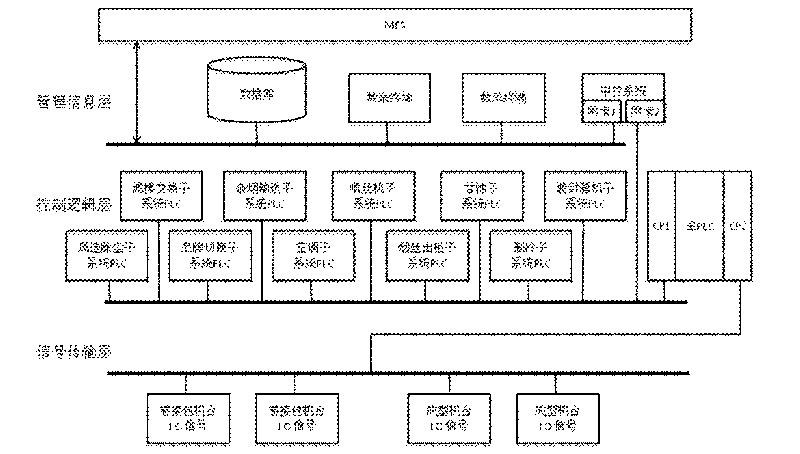

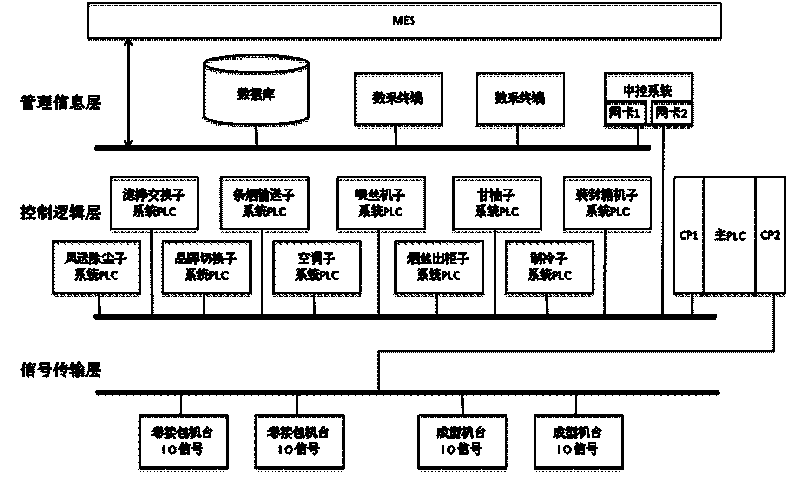

[0035] Such as figure 1 As shown, the system uses Siemens SCALANCE X400 series modular switches as the main network equipment to build an industrial Ethernet communication platform. According to the deployment of network functions, it can be roughly divided into three layers from top to bottom: management information layer, control logic layer, and signal transmission layer.

[0036] 1. Management information layer

[0037] The management information layer is mainly composed of 12 X414-3E and 1 X408-2 modular switches to form a gigabit optical fiber backbone network, which mainly realizes the data acquisition terminal of the coiling charter machine, the data acquisition terminal of the filter rod forming machine, and the comprehensive tester of the machine , central control system server, database server and other equipment network interconnection.

[0038] 2. Control logic layer

[0039] The control logic layer is mainly composed of 6 X414-3E and 1 X408-2 modular switches ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com