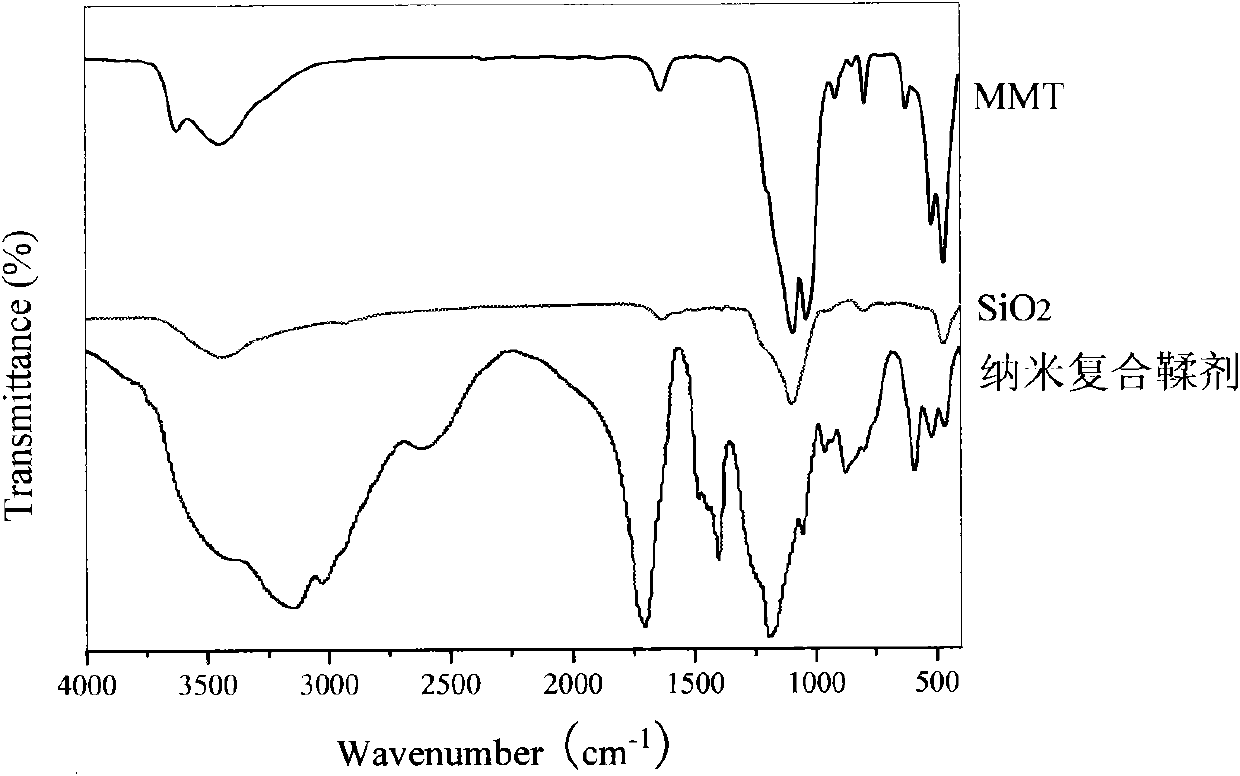

Method for preparing nano-composite tanning agent containing montmorillonite and silica particles

A technology of silica and compound tanning agent, applied in chemical treatment of small hide/big hide/leather/fur, small hide/big hide/leather/fur treatment, tanning treatment, etc., can solve chromium toxicity environment, Pollution, restrictions and other issues, to achieve the effect of meeting production requirements, excellent performance, and improved stability of heat and humidity resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Embodiment 1: First, get 0.6g of montmorillonite and add it into a three-necked flask equipped with 70g of distilled water, stir to make montmorillonite form a uniform suspension, then add 20g of methacrylic acid and 0.2g of surface The active agent hexadecyltrimethylammonium chloride and 0.2g of nano-silica RNS-D with double bonds on the surface were stirred for 30 minutes, ultrasonically treated for 20 minutes, heated in a water bath to 60°C, stirred for 4 hours, and then heated to After 70°C, add dropwise a blend solution of 0.6g of ammonium persulfate, 0.6g of isopropanol and 10g of water. The dropping time is controlled at 30 minutes. After the addition is completed, the temperature is raised to 75°C and reacted for 3 hours. The obtained product is A nanocomposite tanning agent containing montmorillonite and silica particles.

Embodiment 2

[0010] Embodiment 2: First, get 0.6g of montmorillonite and add it into a three-necked flask equipped with 70g of distilled water, stir to make montmorillonite form a uniform suspension, then add 20g of methacrylic acid and 0.8g of surface Active agent 3-chloro-2-hydroxypropyltrimethylammonium chloride and 0.5g of nano-silica RNS-D with double bonds on the surface, stirred for 30 minutes, ultrasonically treated for 20 minutes, heated in a water bath to 60°C, stirred After 4 hours, the temperature was raised to 70°C, and a blend solution of 1.2g of ammonium persulfate, 0.6g of isopropanol and 10g of water was added dropwise, and the dropping time was controlled at 38min. After the addition was completed, the temperature was raised to 80°C, and the reaction was 2.5 h, the resulting product is a nanocomposite tanning agent containing montmorillonite and silica particles.

Embodiment 3

[0011] Embodiment 3: First, get 0.6g of montmorillonite and add it into a three-necked flask equipped with 70g of distilled water, stir to make montmorillonite form a uniform suspension, then add 20g of methacrylic acid and 0.5g of surface Active agent dodecyldimethylbenzyl ammonium chloride and 0.4g of nano-silica RNS-D with double bonds on the surface, stirred for 30min, ultrasonically treated for 20min, heated in a water bath to 60°C, stirred for 4h and then After heating up to 70°C, add dropwise a blend solution of 1.0g of ammonium persulfate, 0.6g of isopropanol and 10g of water. The dropping time is controlled at 35 minutes. After the addition is completed, the temperature is raised to 85°C and reacted for 2 hours. It is a nano-composite tanning agent containing montmorillonite and silica particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com