Fuel cell membrane electrode with renewable function and preparation method thereof

A fuel cell membrane and electrode technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of complex preparation process, no substantial breakthrough in long-life catalysts, and expensive carbon nanotubes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

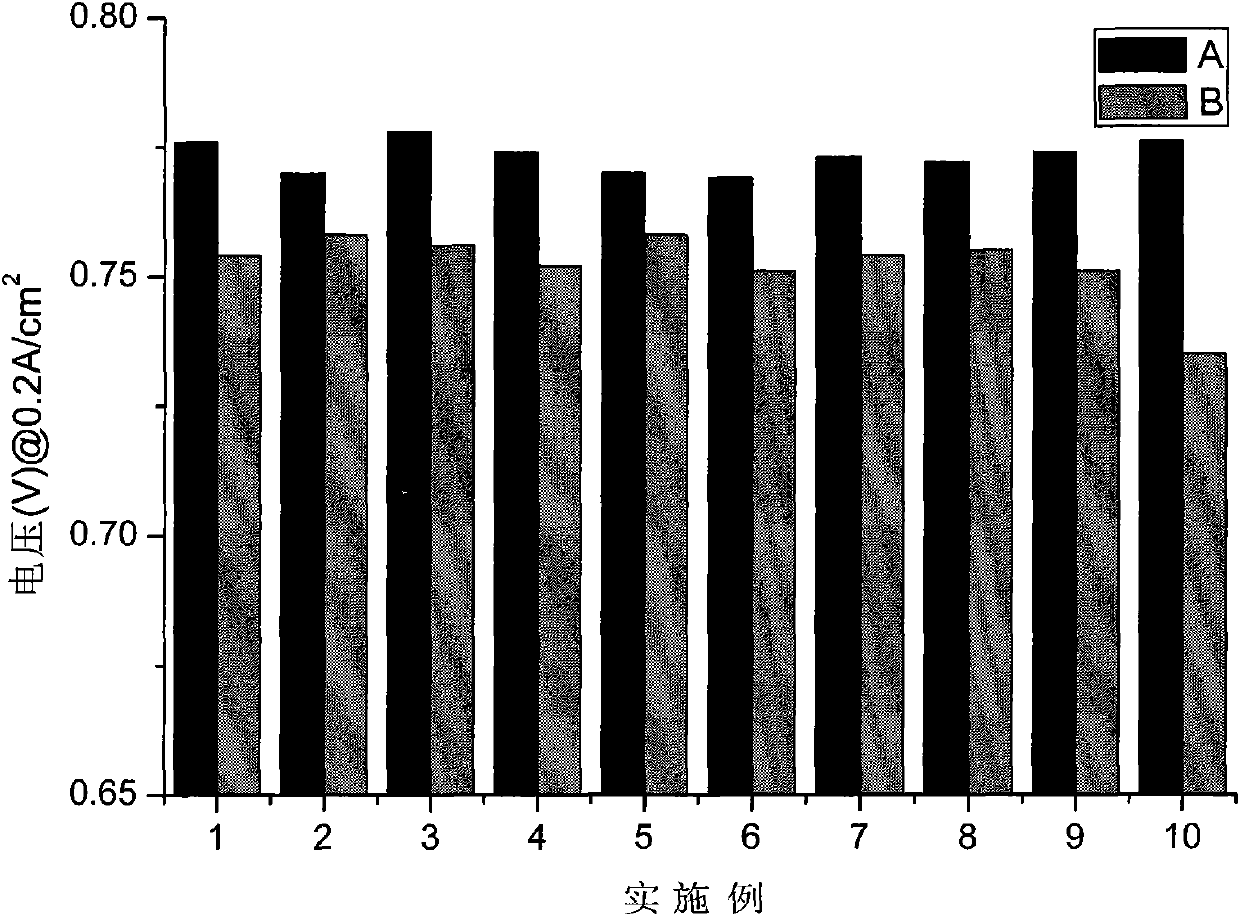

Examples

Embodiment 1

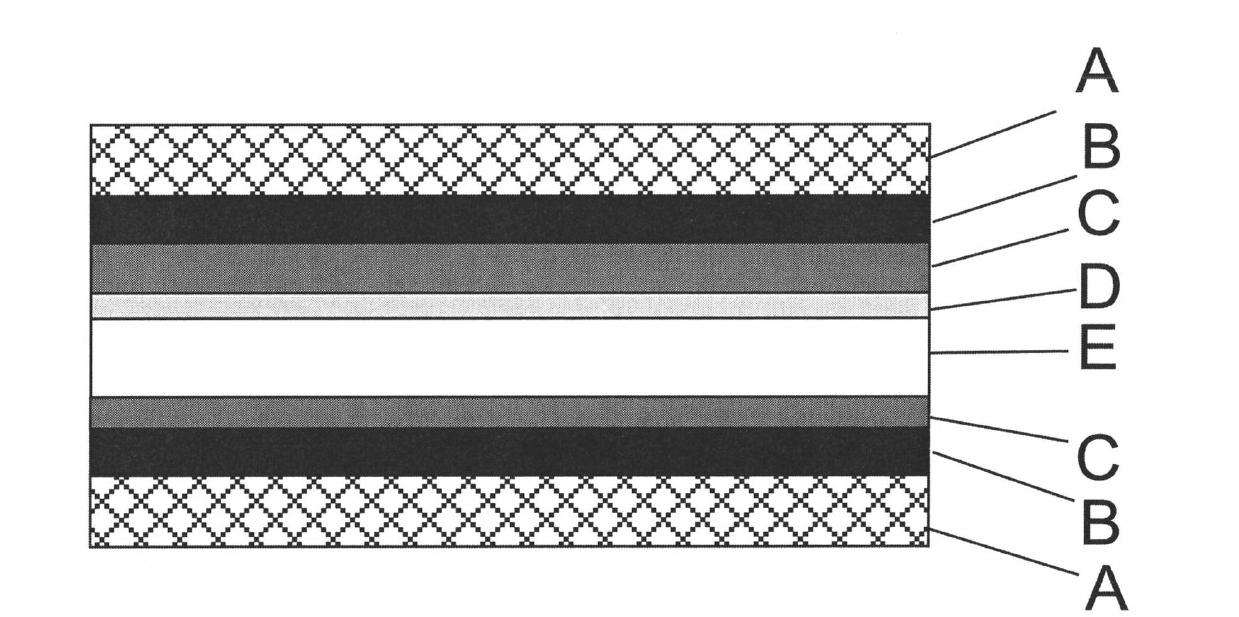

[0036] The preparation steps of the fuel cell membrane electrode with the catalyst layer having a regenerative function are as follows:

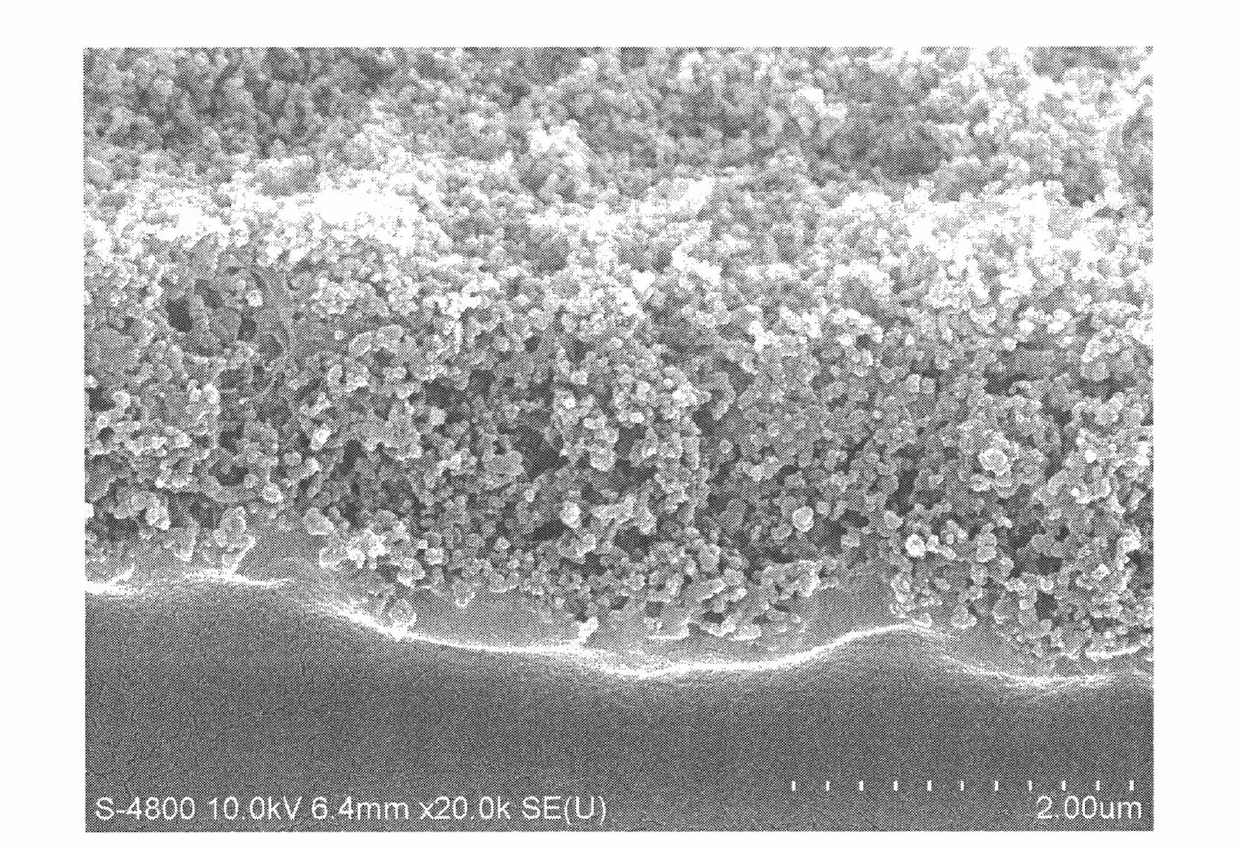

[0037] 1. Preparation of porous carbon slurry

[0038] The domestic activated carbon fiber (specific surface area 1000~1600m 2 / g) with 20wt% H 2 o 2 The solutions were mixed, treated at room temperature for 2 hours, then filtered, rinsed with deionized water, and dried at 100°C for 15 hours. Get the domestic activated carbon fiber of 2.5g oxidation treatment and 19ml 5wt% perfluorosulfonic acid proton exchange resin solution ( DuPont Company) was mixed with 35ml 5% ethanol / deionized aqueous solution, stirred at high speed for 1 hour, and ultrasonically dispersed for 25 minutes;

[0039] 2. Preparation of porous carbon adsorption layer

[0040] The porous carbon slurry is coated on the surface of the gas diffusion layer electrode as the cathode, and dried at 100°C for 12 hours, and the average thickness of the dry coating is about 4 μm...

Embodiment 2

[0050] The preparation steps of the fuel cell membrane electrode with the catalyst layer having a regenerative function are as follows:

[0051] 1. Preparation of porous carbon slurry

[0052] Conductive activated carbon Vulcan XC-72 (produced by U.S. Cabot Company) and 71% HClO 4 Oxidants are mixed, reflux at room temperature for 3-4 hours, then filtered, cleaned with deionized water, and dried at 80-90°C for 15 hours, take 1.5g of oxidized activated carbon and 7ml of 5wt% The solution was mixed with 20ml of deionized aqueous solution, stirred at high speed for 0.5 hours, and ultrasonically dispersed for 10 minutes;

[0053] 2. Preparation of porous carbon adsorption layer

[0054] Same as Example 1, except that the average thickness of the dry coating is about 3 μm;

[0055] 3. Pretreatment of the gas diffusion layer

[0056] Immerse Toray carbon paper in polytetrafluoroethylene hydrophobizing agent for 5 minutes, and calcined at 350°C for 20 minutes, the content of pol...

Embodiment 3

[0064] The preparation steps of the fuel cell membrane electrode with the catalyst layer having a regenerative function are as follows:

[0065] 1. Preparation of porous carbon slurry

[0066] Domestic coconut shell carbon (specific surface area greater than 1000m 2 / g) with 20% H 2 o 2 The solutions were mixed, treated at room temperature for 2 hours, then filtered, rinsed with deionized water, and dried at 90°C for 20 hours. Take 4.0g of oxidized coconut shell carbon and 90ml of 5wt% Flemion solution, and mix with 240ml of deionized water Mixing, high-speed stirring for 0.5 hours, and ultrasonic dispersion for 15 minutes;

[0067] 2. Preparation of porous carbon adsorption layer

[0068] The porous carbon slurry was coated on the side of NRE 212CS as the cathode, and dried at 100°C for 20 hours, and the average thickness of the dry coating was about 2 μm;

[0069] 3. Pretreatment of the gas diffusion layer

[0070] Same as embodiment 2;

[0071] 4. Preparation of gas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com