Pt-TiO2/CNTs catalyst and preparation method thereof

A pt-tio2, catalyst technology, used in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of current density, fuel cell energy and power density, low conductivity, and improved catalytic performance of catalysts not obvious problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Take 4ml TiCl 4 The liquid was slowly diluted with distilled water dropwise to a yellow-green transparent solution, and then weighed 0.3g with H 2 SO 4 / HNO 3 The carbon nanotubes (CNTs) obtained by heating the mixed acid under reflux (H 2 SO 4 and HNO 3volume ratio of 3:1, temperature 100°C, time 4h), then add 10ml of ethanol, ultrasonic treatment for 1 hour, add 60ml of 10M NaOH solution dropwise under stirring, continue ultrasonic treatment for 2 hours, and transfer the mixture into a hydrothermal reaction kettle React at 180°C for 18 hours, wash with deionized water and 0.1M HCl solution until neutral, filter, and dry in vacuo.

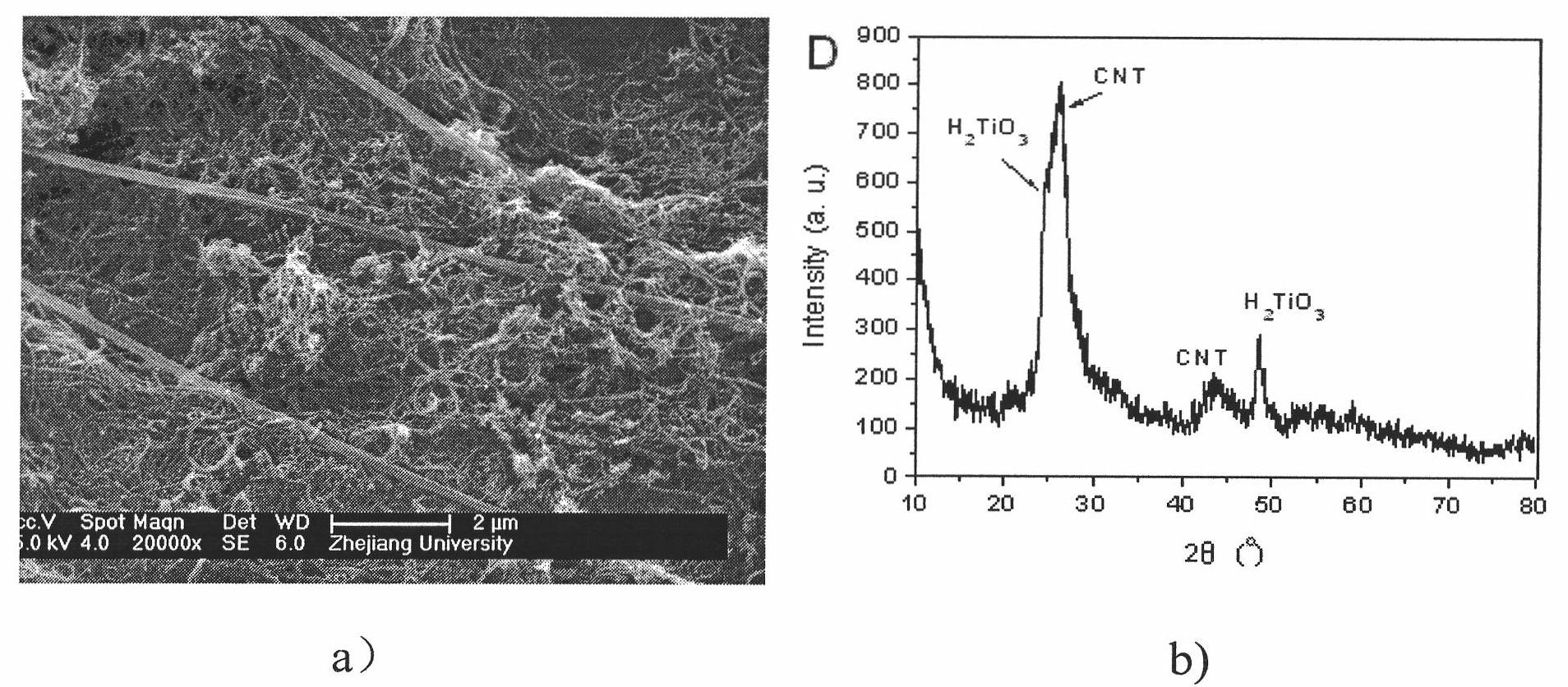

[0022] 2) Put the dried powder into a quartz boat, raise the temperature to 450° C. under the protection of nitrogen, heat-treat for 2 hours, and take out the heat-treated powder after cooling to room temperature. figure 1 The XRD characterization of the first step shows that the product obtained by hydrothermal is H 2 TiO 3 / CNT...

Embodiment 2

[0029] 1) Take 8ml TiCl 4 The liquid was slowly diluted with distilled water dropwise to a yellow-green transparent solution, and then weighed 0.3g with H 2 SO 4 / HNO 3 The solution was heated to reflux treated carbon nanotubes (CNTs) in it (H 2 SO 4 and HNO 3 volume ratio of 3:1, temperature 100°C, time 4h), then add 10ml of ethanol, ultrasonic treatment for 1 hour, add dropwise 70ml of 10M NaOH solution under stirring, continue ultrasonic treatment for 2 hours, and transfer the mixture into a hydrothermal reaction kettle React at 180°C for 20 hours, wash with deionized water and 0.1M HCl solution until neutral, filter, and dry in vacuo.

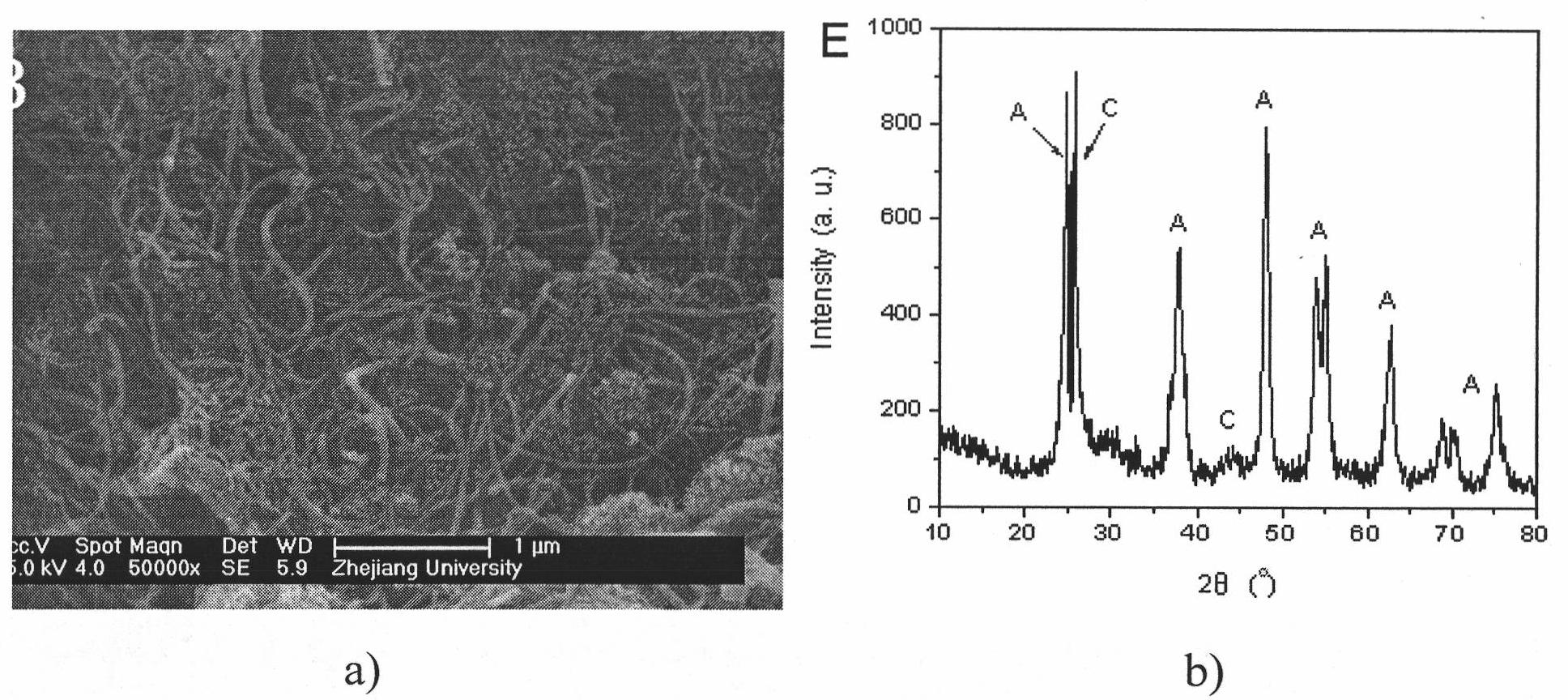

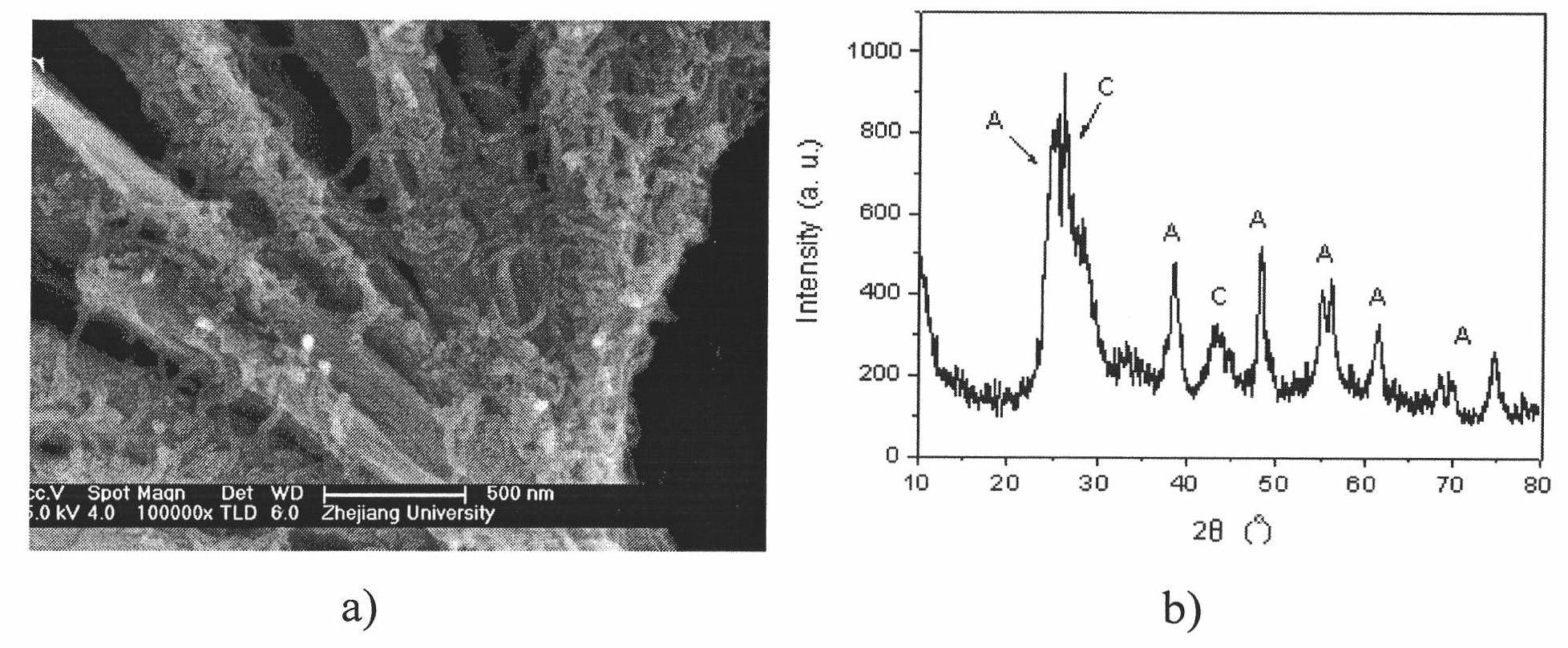

[0030] 2) Put the dried powder into a quartz boat, raise the temperature to 450° C. under the protection of nitrogen, and heat-treat for 2 hours. After cooling to room temperature, take out the heat-treated powder and disperse it in 10M NaOH solution, conduct the second hydrothermal reaction at 180°C for 20 hours, wash with deionized ...

Embodiment 3

[0037] 1) Take 4ml TiCl 4 The liquid was slowly diluted with distilled water dropwise to a yellow-green transparent solution, and then weighed 0.45g with H 2 SO 4 / HNO 3 The carbon nanotubes (CNTs) obtained by heating the mixed acid under reflux (H 2 SO 4 and HNO 3 volume ratio of 3:1, temperature 100°C, time 4h), then add 10ml of ethanol, ultrasonic treatment for 1 hour, add 70ml of 10M NaOH solution dropwise under stirring, continue ultrasonic treatment for 2 hours, and then transfer the mixture to hydrothermal reaction React in the kettle at 180°C for 15 hours, wash with deionized water and 0.1M HCl solution until neutral, filter, and dry in vacuum.

[0038] 2) Put the dried powder into a quartz boat, raise the temperature to 450° C. under the protection of nitrogen, and heat-treat for 2 hours. After cooling to room temperature, take out the heat-treated powder and disperse it in 10M NaOH solution, conduct the second hydrothermal reaction at 180°C for 18 hours, wash w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com