Titanium catalyst and preparation method and application thereof

A titanium catalyst and catalyst technology, which are used in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc. and other problems, to achieve the effect of improving catalytic activity, short esterification reaction and polymerization reaction time, and high intrinsic viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

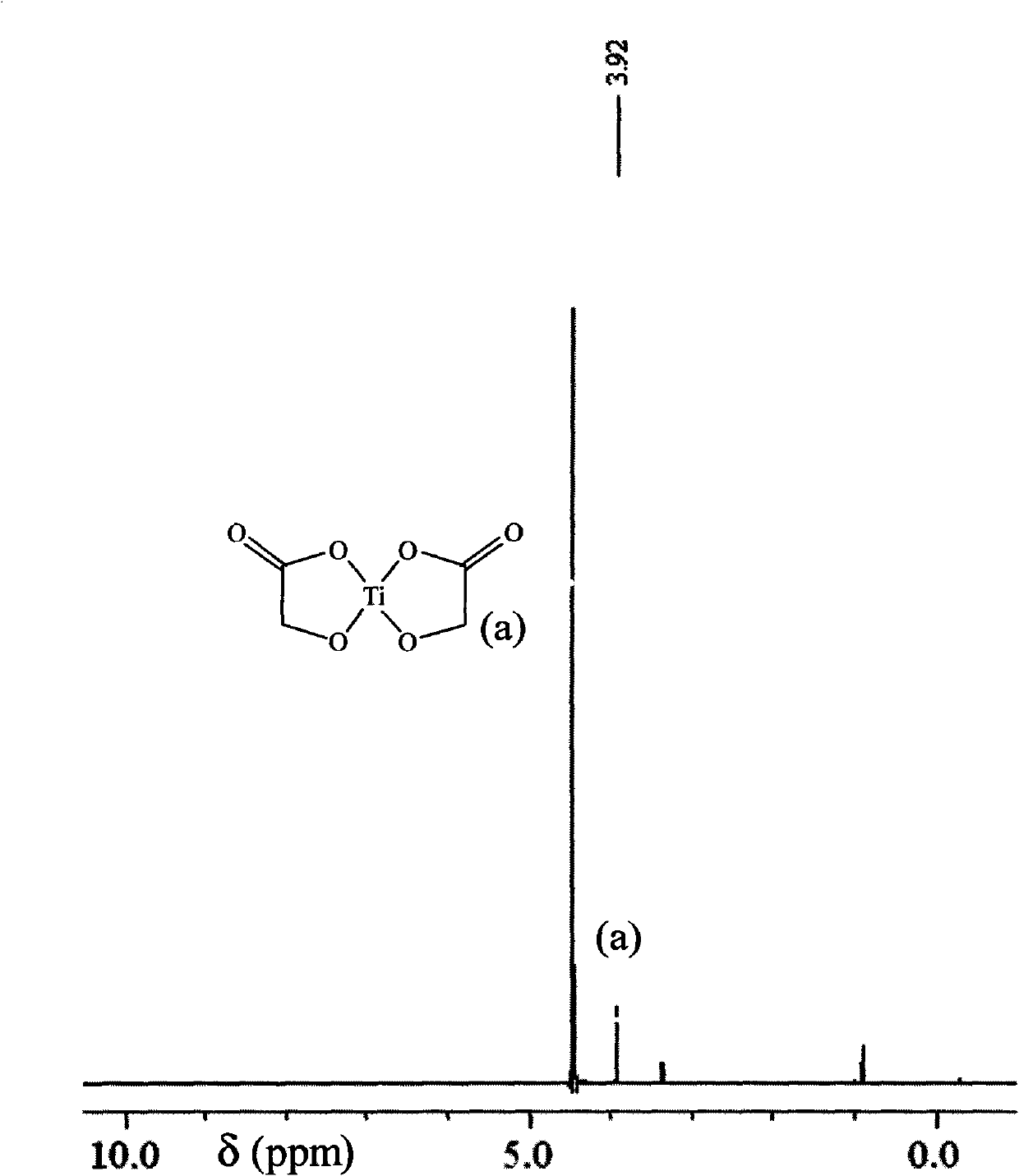

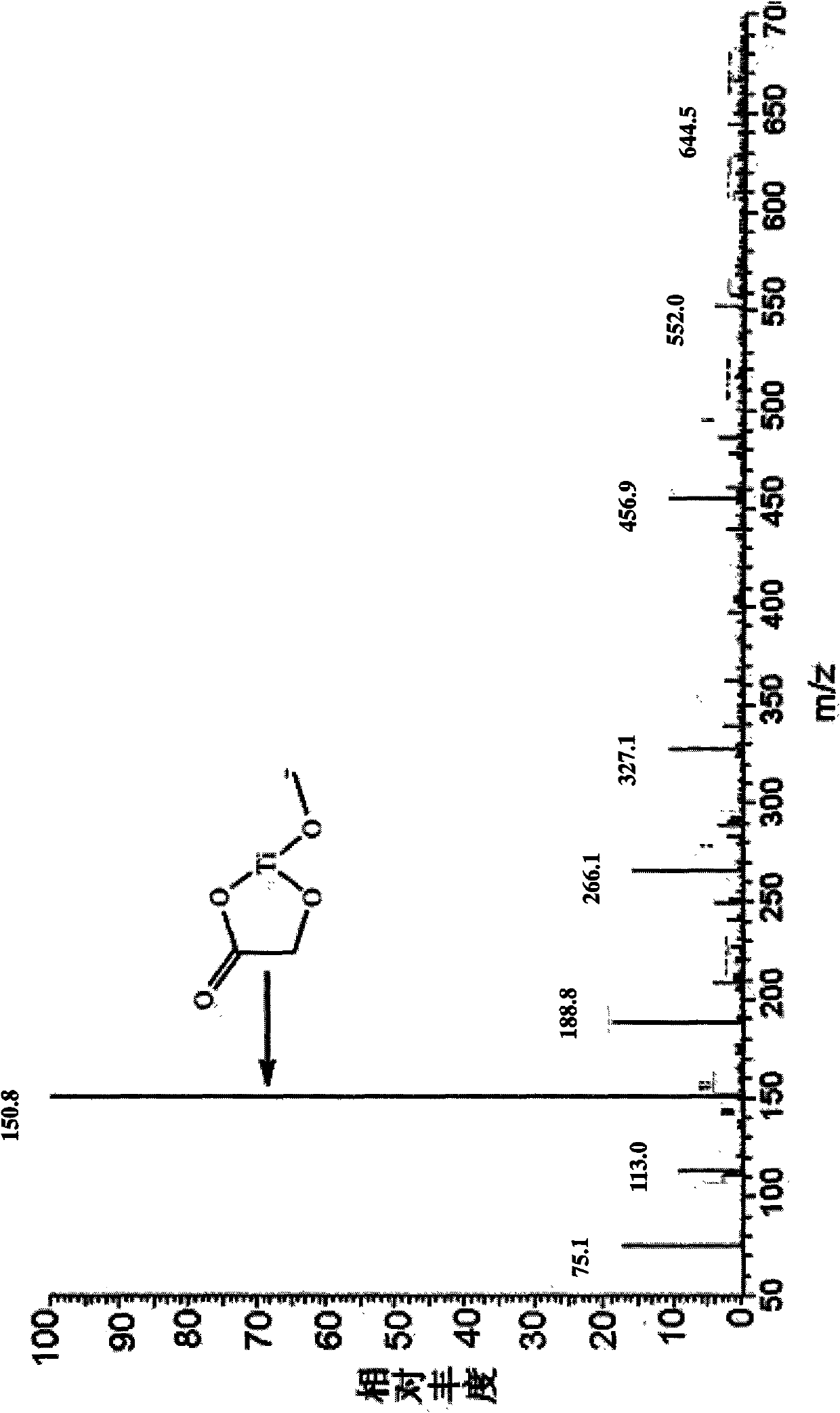

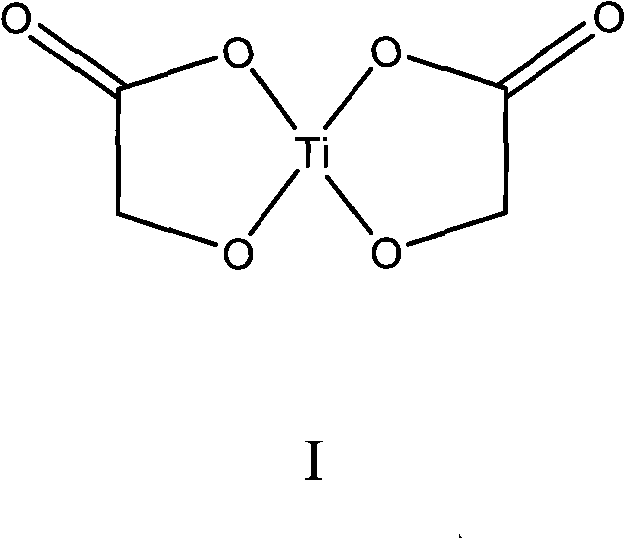

[0023] Weigh 18.38 grams of α-glycolic acid (Sinopharm Chemical Reagent Co., Ltd., chemically pure), put it into a 250-ml round-bottomed single-necked flask, measure 60 mL of tetrahydrofuran and pour it into the flask, magnetically stir to dissolve α-glycolic acid, and heat up to At 60°C (oil bath temperature, the same below), add 40.84g of butyl titanate (Tianjin Fuchen Chemical Reagent Factory, chemically pure) dropwise with a constant pressure dropping funnel, a large amount of white precipitates are produced, and the dropwise addition is completed in 1 hour. Heat up to tetrahydrofuran reflux, continue to stir and react for 2.5 hours, cool to room temperature, carefully filter with suction, wash with a small amount of absolute ethanol several times, drain, dry in a blast oven at 70°C for several hours, and weigh 22.57g , the yield was 96%.

Embodiment 2

[0025] Put 91.46 grams of α-glycolic acid (Shanghai Aladdin Reagent Factory, purity 99.5%) into a 1000mL three-necked flask, then pour 150mL of absolute ethanol (analytical grade), stir magnetically, heat up to 65°C, and wait for α-glycolic acid After it was completely dissolved, 204.17 g of butyl titanate (Tianjin Fuchen Chemical Reagent Factory, chemically pure) was added dropwise through a constant-pressure dropping funnel. A large amount of white precipitates were produced, and the addition was completed in about 1 hour. Continue to stir and react at this temperature for 2.5 hours, cool to room temperature, carefully suction filter, wash 3 times with a small amount of absolute ethanol, drain, dry in a blast oven at 70°C for several hours, and weigh 106.26 grams. The yield is 90%.

Embodiment 3

[0027] Weigh 91.30 grams of α-glycolic acid (Shanghai Aladdin Reagent Factory, purity 99.5%) in a 1000mL three-necked flask, then pour 150mL of absolute ethanol (analytical grade), and stir magnetically. After the α-glycolic acid is completely dissolved, Add 204.04 g of butyl titanate (Tianjin Fuchen Chemical Reagent Factory, chemically pure) dropwise at room temperature, and finish the dropwise addition in 3 hours. Only when more butyl titanate is added dropwise will white precipitate occur. Continue to stir and react for 2 hours at room temperature , carefully suction filtered, washed 3 times with a small amount of absolute ethanol, drained, dried in a blast oven at 90°C for 5 hours, and weighed to obtain 104.48 grams of titanium α-hydroxyacetate, with a yield of 89%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com