Polycarboxylic acid concrete plasticizer and synthesis thereof

A plasticizer and polycarboxylic acid technology, applied in the field of concrete admixtures, can solve the problems of complex preparation process and difficult control of operation, and achieve the effects of simple production process, stable quality and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

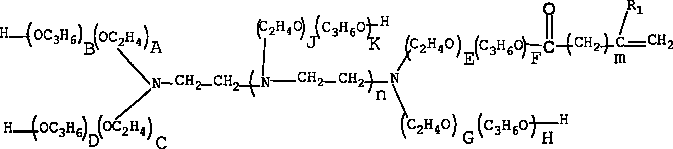

[0033] In this embodiment, the monoesterification of polyene polyamine-based polyethylene glycol with the following structure is selected as monomer A:

[0034]

[0035] In a four-necked flask equipped with a thermometer and a stirrer, add 175g of monoester (molecular weight 2965) and 40g of water of polyene polyamine-based polyethylene glycol with the structure shown above, heat up to melting, add 5g (35% ) hydrogen peroxide, dropwise 15% sodium sulfite (1.4g) and sodium methacrylate (25g) aqueous solution 169.3g, 60% maleic anhydride aqueous solution 83.3g simultaneously. Wherein the sodium sulfite solution was dropped in 2.5 hours, and the maleic anhydride aqueous solution was dropped in 1.5 hours. During the reaction process, the temperature was controlled at 30°C, and after the dropwise addition was completed, the temperature was kept for 30 minutes. Adjust the pH value to 7 with 30% sodium hydroxide to obtain a polycarboxylate plasticizer with a weight average molecu...

Embodiment 2

[0037] In a four-necked flask equipped with a thermometer and a stirrer, add 175g of monoester and 61g of water with the polyene polyamine-based polyethylene glycol of Example 1, heat up to melting, add 5.3g (35%) hydrogen peroxide, Simultaneously, 111.6 g of 15% sodium sulfite (1.75 g) and sodium methacrylate (15 g) aqueous solution, and 125 g of 60% maleic anhydride aqueous solution were added dropwise. Wherein the sodium sulfite solution was dropped in 2.5 hours, and the maleic anhydride aqueous solution was dropped in 1.5 hours. During the reaction process, the temperature was controlled at 40°C, and after the dropwise addition was completed, the temperature was kept for 30 minutes. Adjust the pH value to 6 with 30% sodium hydroxide to obtain a polycarboxylate plasticizer with a weight average molecular weight of about 18,000.

Embodiment 3

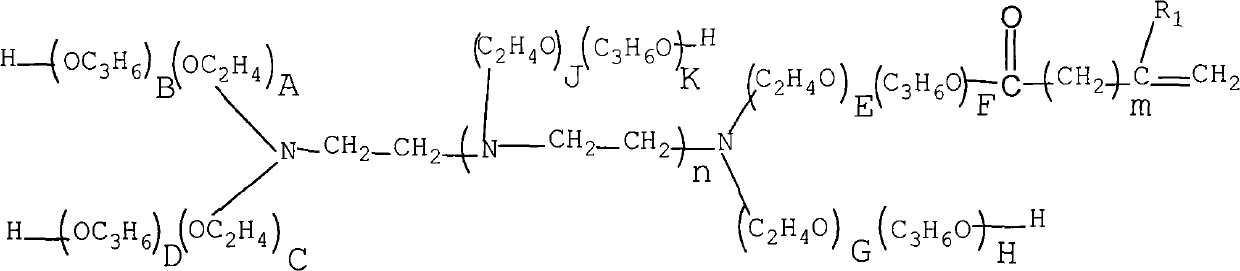

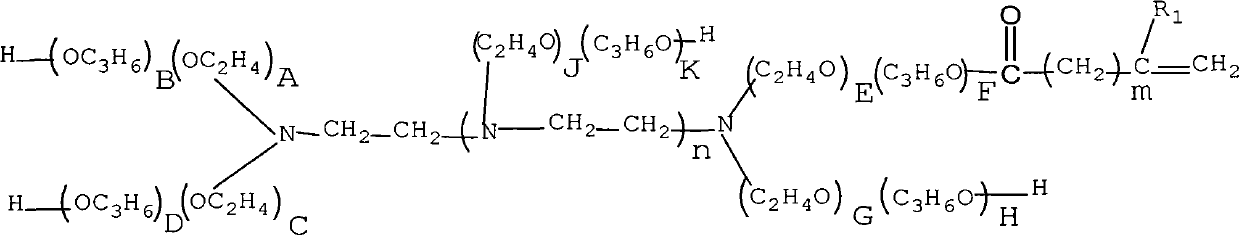

[0039] In this embodiment, the monoesterification of polyene polyamine-based polyethylene glycol with the following structure is selected as monomer A:

[0040]

[0041] In a four-necked flask equipped with a thermometer and a stirrer, add 175g of the polyene polyamine-based polyethylene glycol monoester (molecular weight: 2978) and 85g of water with the structure shown above, heat up to about 50°C and melt, add 6g (35%) hydrogen peroxide, dropwise simultaneously 15% sodium sulfite (2.45g) and sodium methacrylsulfonate (20g) aqueous solution 149.6g, 60% maleic anhydride aqueous solution 145.8g. Wherein the sodium sulfite solution was dropped in 2.5 hours, and the maleic anhydride aqueous solution was dropped in 1.5 hours. During the reaction process, the temperature was controlled at 50°C, and after the dropwise addition was completed, the temperature was kept for 30 minutes. Then lower the temperature to 40° C., adjust the pH value to 8 with 30% sodium hydroxide to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com