Purification method for obtaining high-purity carbon nano tube

A carbon nanotube and purification method technology, applied in nanotechnology, nanotechnology, nanostructure manufacturing and other directions, can solve the problems of harsh conditions, uneconomical, low crystalline graphite carbon impurity removal efficiency, etc., and achieves good stability and operating conditions. less demanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

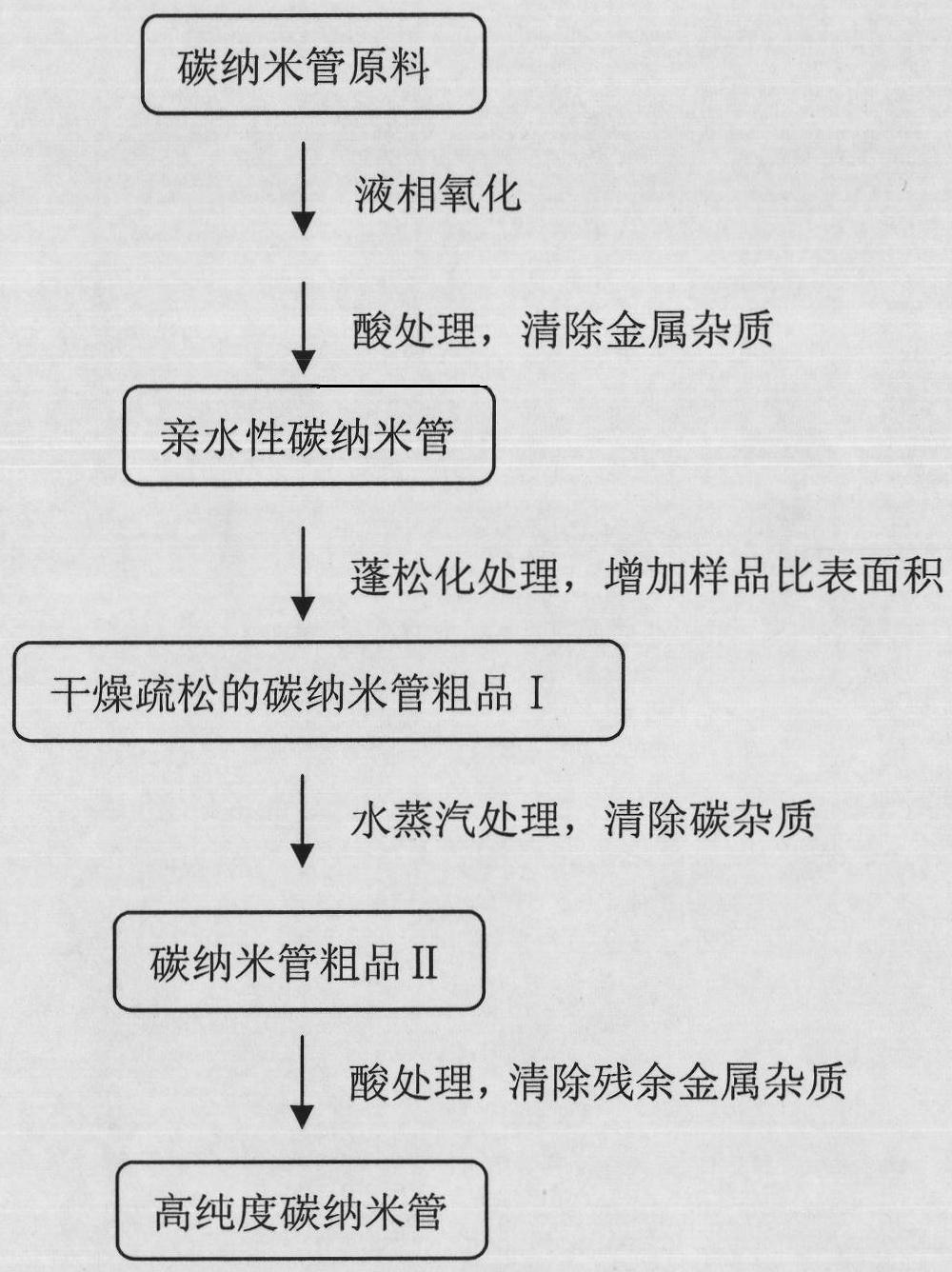

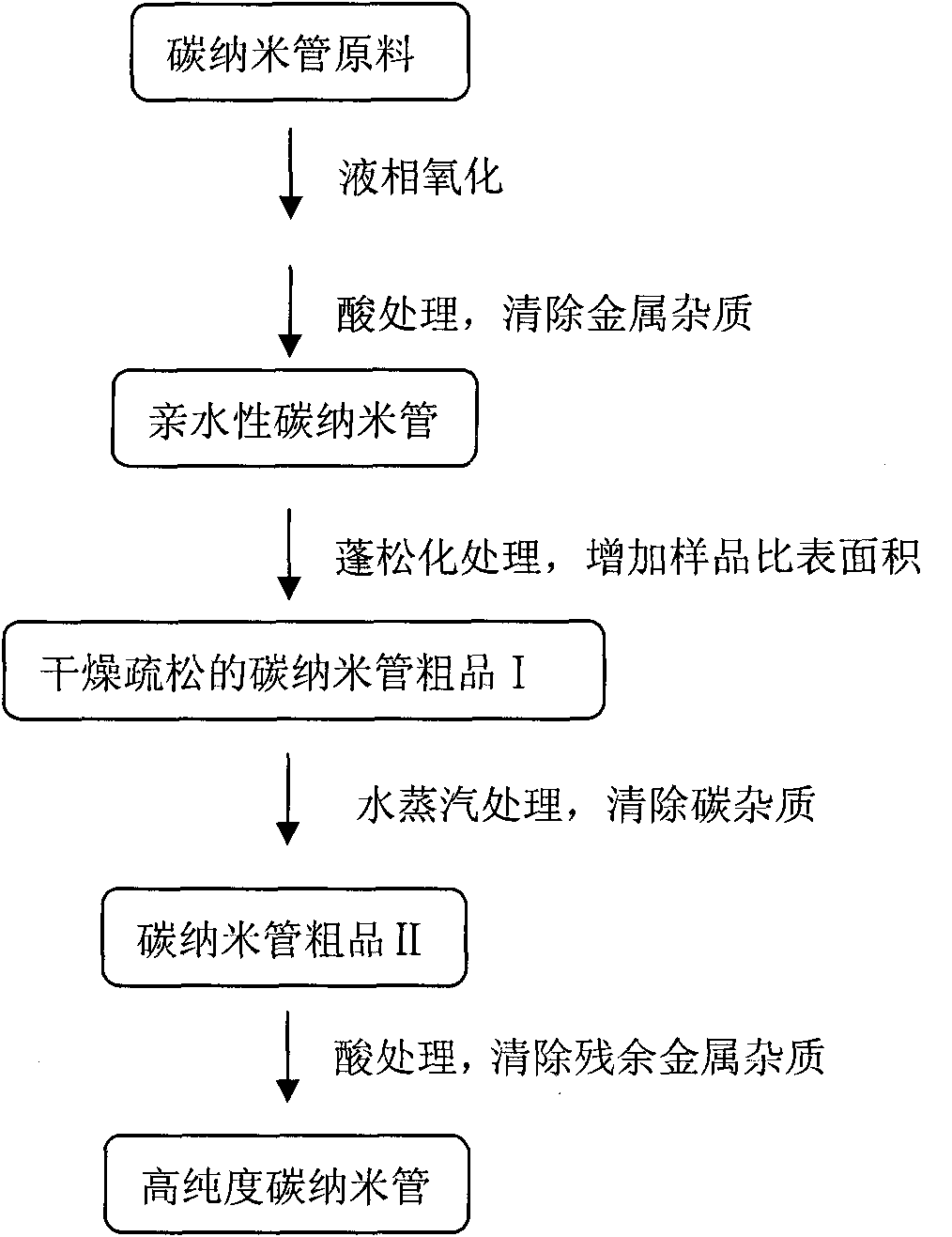

Method used

Image

Examples

Embodiment 1

[0035] Take 600mg of arc-produced SWNTs in 600ml of HNO 3 (2.6M) was refluxed for 6h, after vacuum filtration, the filter cake was dispersed in 600ml of HCl (6M) and refluxed for 12h, after vacuum filtration, the solid filter cake was washed to neutrality.

[0036] Remove the solid filter cake, ultrasonically disperse it in 100ml deionized water, and stir it properly to make it more uniform. Then the single-walled carbon nanotube aqueous solution was put into three 50ml plastic centrifuge tubes in equal portions, quick-frozen in liquid nitrogen, and dried into a fluffy flocculent solid product with freeze-drying equipment.

[0037] Then it was treated with water vapor at 900°C (Ar gas was bubbled in water at 98°C to carry water vapor, the flow rate was 100ml / min) for 2 hours. The single-walled carbon nanotubes treated with water vapor were then soaked in HCl (6M) overnight, filtered to remove acid, and washed with deionized water until neutral.

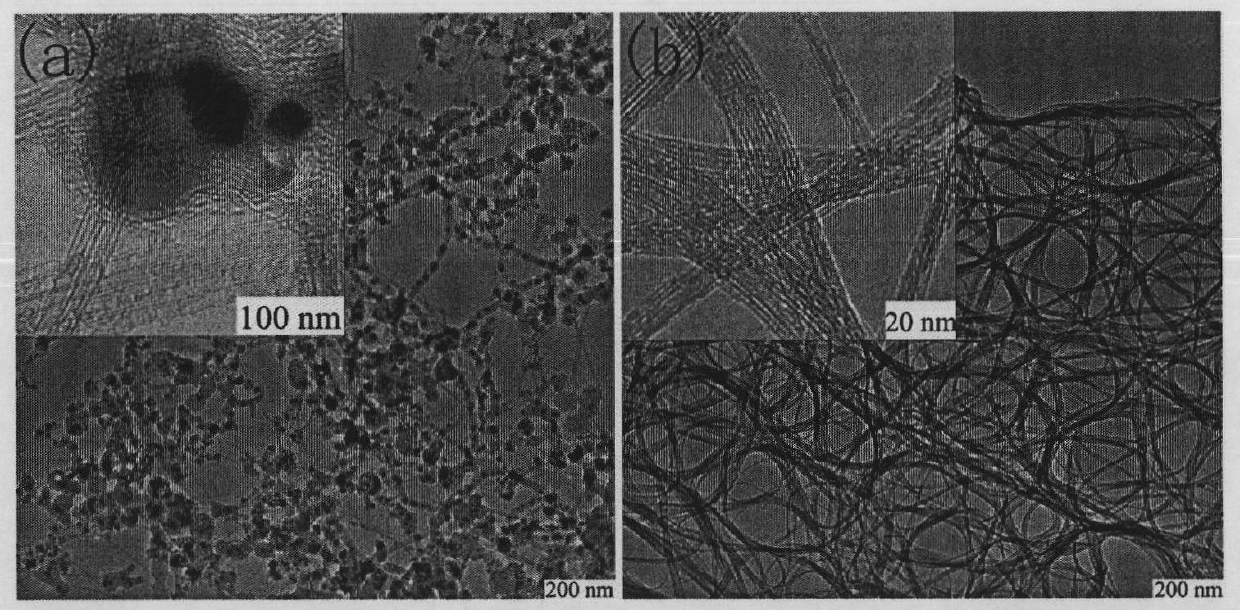

[0038] The electron micrograph...

Embodiment 2

[0042] Take 200mg of arc-produced double-walled carbon nanotubes in 100ml of HNO 3 (5.2M) backflow 12h, after decompression filtration, filter cake is dispersed in the H of 150ml 2 SO 4 (4M) was refluxed for 6 hours, and after vacuum filtration, the solid filter cake was washed to neutrality.

[0043] Remove the solid filter cake, ultrasonically disperse it in 100ml deionized water, and stir it properly to make it more uniform. Then the acid-oxidized double-walled carbon nanotube aqueous solution was packed into three 50ml plastic centrifuge tubes in equal portions, quick-frozen in liquid nitrogen, and dried into a fluffy flocculent solid product with freeze-drying equipment.

[0044] Then steam treatment at 900° C. (Ar gas flow rate 200 ml / min, bubbling in water at 90° C. to carry water vapor) for 4 hours. The steam-treated double-walled carbon nanotubes were then soaked in HCl (10M) for 24 hours, filtered to remove acid, and washed with deionized water until neutral.

[...

Embodiment 3

[0047] Get 1000mg of single-walled carbon nanotubes prepared by CVD, and process them according to the method of Example 1, but steps 1) and 2) use 1000ml hydrogen peroxide (mass concentration 15%) and 300ml HCl (10M) solutions respectively, and reflux treatment respectively 2h and 4h, and then filtered under reduced pressure, the filter cake was vacuum-dried and thoroughly ground for 6h to become a fluffy flocculent solid product.

[0048] It was then treated with water vapor (Ar gas flow rate 80ml / min in water at 98°C to carry water vapor) at 800°C for 4 hours. The single-walled carbon nanotubes treated with water vapor were then soaked in HCl (2M) for 6 hours, filtered to remove acid, and washed with deionized water until neutral.

[0049] Purified CVD single-walled carbon nanotubes: Raman spectroscopy I G / I D =42.4, thermogravimetric analysis purity: 90% (silicate is contained in the raw material).

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com