Method for separating and purifying coptisine monomers

A technology for separation and purification of coptisine, which is applied in the field of separation and purification of coptisine monomer, can solve problems such as inability to strengthen the determination of coptisine content, no coptisine, lack of high purity, etc., achieve good separation effect, easy to scale up production, and easy The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

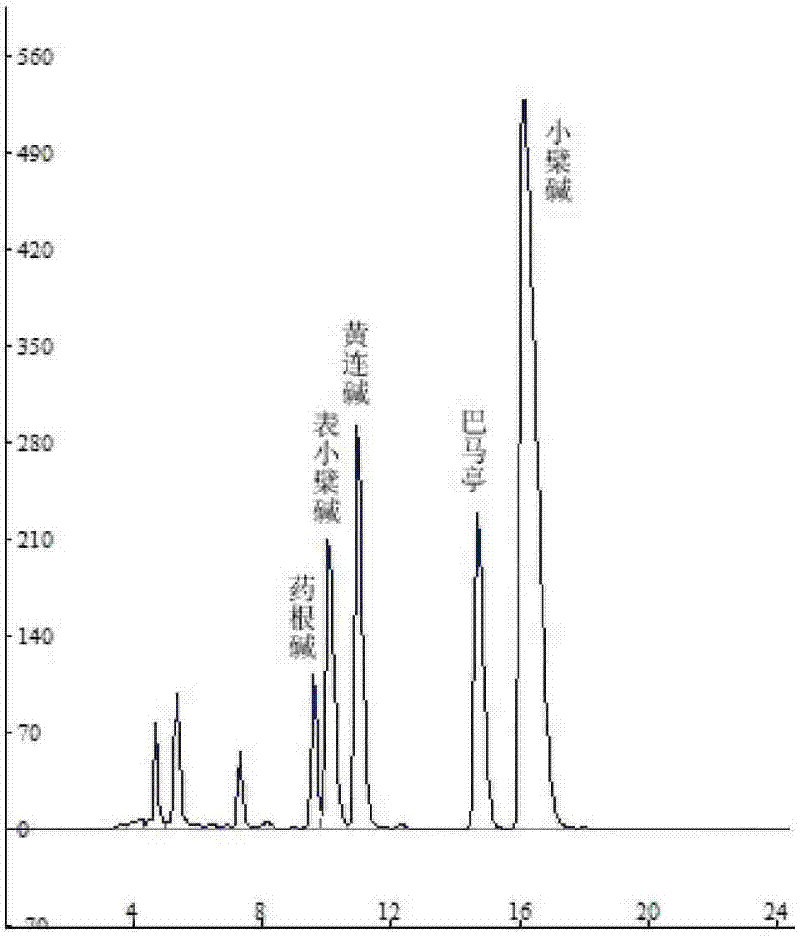

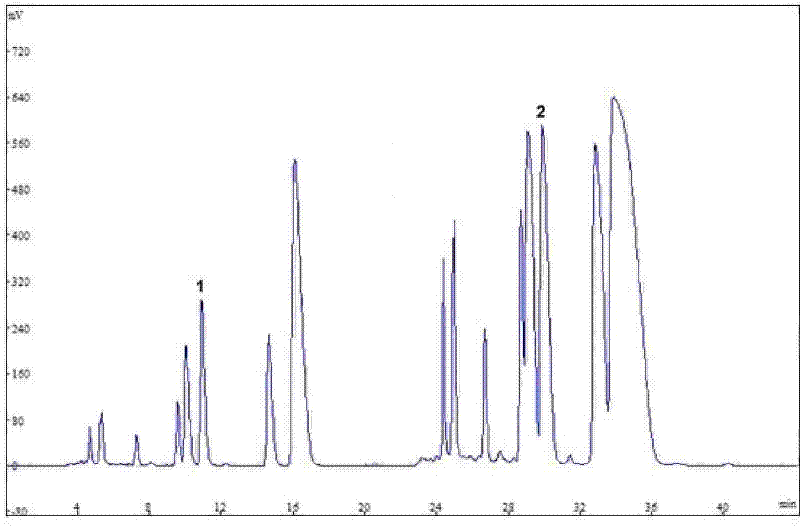

Image

Examples

Embodiment 1

[0047] The separation and purification method of coptisine monomer of the present embodiment comprises the following main steps:

[0048] (1), extraction:

[0049] Take 1 kg of Coptidis Rhizoma, crush it into a coarse powder, add 10 L of 85% ethanol solution by volume, reflux extraction 3 times, each time for 2 hours, filter, collect, and combine the filtrates (the dregs are evaporated to dryness to recover ethanol).

[0050] (2), concentration:

[0051] The filtrate collected and combined in step (1) is recovered with ethanol, concentrated to a relative density of 1.10g / mL (measured at about 90°C), left to stand for crystallization for 8 hours, filtered, and the precipitate is removed (the crystal in the precipitate is Berberis Alkaline, separately purified to obtain the berberine product), coptisine is mainly retained in the filtrate, and the obtained filtrate (about 1.5 L) is subjected to the next step of extraction treatment.

[0052] (3), extraction:

[0053] Add ammon...

Embodiment 2

[0068] The separation and purification method of coptisine monomer of the present embodiment comprises the following major steps:

[0069] (1), extraction:

[0070] Take 10 kg of Coptidis Rhizoma, crush it into a coarse powder, add 80 L of 95% ethanol solution by volume, reflux extraction 4 times, each time for 3 hours, filter, collect and combine the filtrates (the dregs are evaporated to dryness to recover ethanol).

[0071] (2), concentration:

[0072] The filtrate collected and combined in step (1) is recovered to ethanol, concentrated to a relative density of 1.05g / mL (measured at about 90°C), left to stand for crystallization for 12 hours, filtered, and the precipitate is removed (the crystal in the precipitate is Berberis Alkaline, separately purified and processed to obtain the berberine product), Coptisine is mainly retained in the filtrate, and the obtained filtrate (about 30L) is subjected to the next step of extraction treatment.

[0073] (3), extraction:

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com