Organic silicon dehydrogenation condensed type optical cable adhesive and use method thereof

A silicone, condensation-type technology, used in adhesives, adhesive additives, polymer adhesive additives, etc.

Active Publication Date: 2012-08-08

CHINA BLUESTAR CHENGRAND CO LTD

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

It can be seen that the existing non-dehydrogenation condensation adhesives cannot meet this requirement at all.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

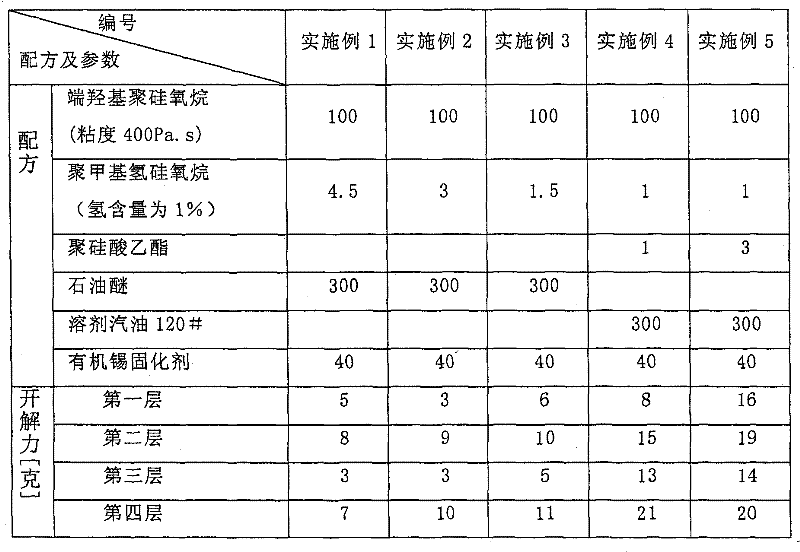

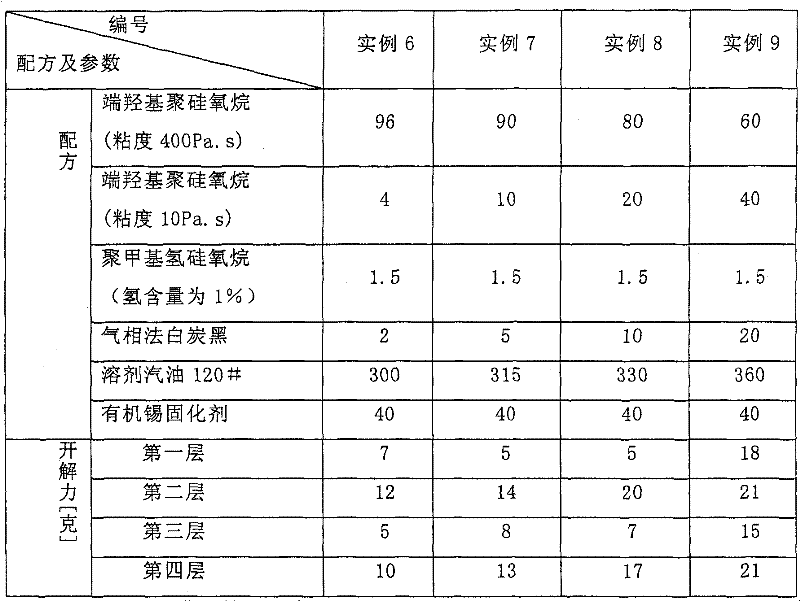

Embodiment 1

[0031] Example 2

Embodiment 2

[0033] Example 3

Embodiment 3

[0035] Example 4

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Login to View More

Abstract

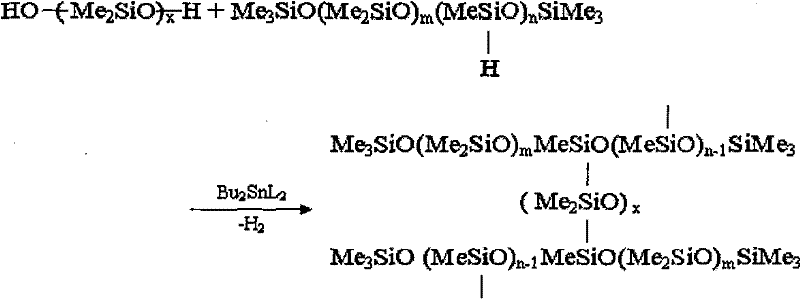

The invention relates to a dehydrogenation condensed type optical cable adhesive and a use method thereof. The A component substance of the adhesive is a sizing material obtained by the steps of taking hydroxy-terminated polydimethylsiloxane as a basic polymer, adding polymethyl hydrogen siloxane and fumed silica and mixing evenly; and the B component substance of the adhesive is an organic tin curing agent prepared by dissolving dibutyltin dilaurate in 120# solvent gasoline or petroleum ether. When in use, the A component substance of the sizing material is dissolved in the 120# solvent gasoline or the petroleum ether with the boiling range of 90 to 120 DEG C in advance, then the mixture is coated on the surface of an optical cable by brush coating or dip coating after the solution and the curing agent are mixed evenly, and an optical cable winding is prepared by winding after curing. The adhesive has moderate bonding strength, ageing resistance and high / low-temperature resistance, the inherent shape of the bonded optical cable winding can keep stable in the processes of storage, transportation and paying off, the resistance generated when the optical cable winding is paid off athigh speed is also minimum without the deviation of the coils of the optical cable, and the signal transmission of the optical cable is also not influenced.

Description

technical field [0001] The invention relates to a silicone optical cable adhesive, in particular to a dehydrogenation condensation optical cable adhesive and its application method. The adhesive can not only be used for the bonding and setting of optical cable windings, but also is easy to untie and can meet the requirements of high-speed payout, so it is especially suitable for long-distance optical cable transmission fields, such as communications, meteorological department sounding balloon control, signal transmission and High-tech applications such as traction and throwing across obstacles, as well as the field of defense wired guidance. Background technique [0002] As far as the optical cable adhesive with silicone material as the main body is concerned, the DC-1-2577 used in the United States is a one-component solvent-type room temperature vulcanizing silicone resin with medium viscosity, and the cured product has high hardness and high strength. When used for the b...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09J183/06C09J11/08C09J11/04

Inventor 李龙锐唐小斗周远建

Owner CHINA BLUESTAR CHENGRAND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com