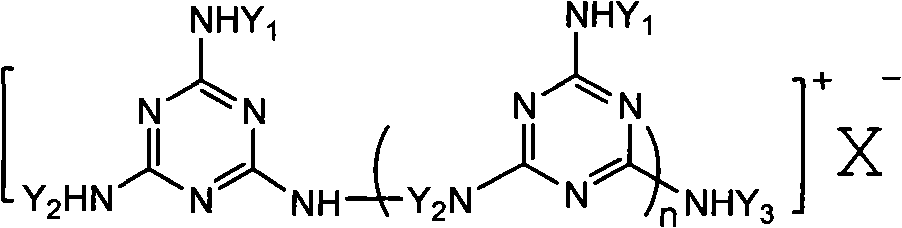

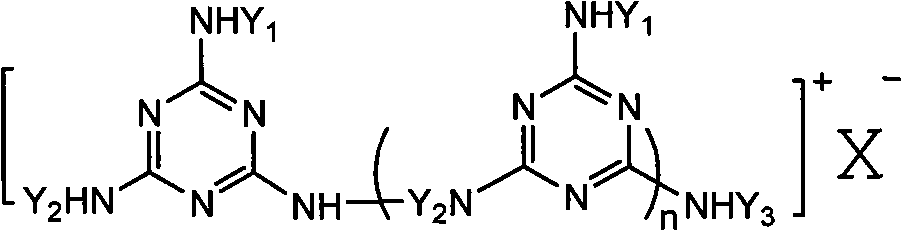

Materials of high flame-retardancy organic intercalation layered clay and preparation method thereof

A layered clay, high flame retardant technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of low ion concentration, poor solubility, and the influence of ion exchange reaction, and achieve comprehensive performance improvement, phase Good capacity and the effect of improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] First, 5 grams of montmorillonite with a total amount of cation exchange of 90 mmol / 100 g was added to 250 ml of dispersion medium water with high-speed stirring or ultrasonic vibration to form a stable suspension, and left to stand, and the coarser particles in the lower layer were filtered off to obtain the filtrate. use. Disperse 6.3 grams of melamine in 100ml of deionized water, heat to 90°C, stir at high speed to form a stable dispersion system, dilute 8.35ml, 36.5% concentrated hydrochloric acid with 50ml of deionized water, add dropwise, and control the temperature during the addition of hydrochloric acid. Stirring speed to prevent agglomeration. After the addition, keep the temperature constant, react for 1.5 hours, cool, precipitate, filter, and wash until nearly neutral, and the white powdery solid obtained is melamine hydrochloride. Dissolve an appropriate amount of melamine hydrochloride in 50ml of water, heat and stir to form a colorless solution, then slow...

Embodiment 2

[0043] First, 5 grams of montmorillonite with a total amount of cation exchange of 90 mmol / 100 g was added to 250 ml of dispersion medium water with high-speed stirring or ultrasonic vibration to form a stable suspension, and left to stand, and the coarser particles in the lower layer were filtered off to obtain the filtrate. use. Disperse 6.3 grams of melamine in 100ml of deionized water, heat to 90°C, and stir at high speed to form a stable dispersion system. Dilute 3.55ml of 85% concentrated phosphoric acid with 25ml of deionized water and add dropwise. When half of the phosphoric acid is added , increase the stirring speed to prevent agglomeration, after the feeding is completed, keep the temperature constant, and react for 2.5 hours to obtain a milky white suspension that is a melamine phosphate suspension. 5.57ml of 36.5% hydrochloric acid was diluted with 50ml of deionized water, slowly added dropwise, and reacted for 1.5 hours to form a transparent and clear solution. ...

Embodiment 3

[0046] First, 5 grams of montmorillonite with a total amount of cation exchange of 90 mmol / 100 g was added to 250 ml of dispersion medium water with high-speed stirring or ultrasonic vibration to form a stable suspension, and left to stand, and the coarser particles in the lower layer were filtered off to obtain the filtrate. use. Disperse 12.75 grams of melamine urea cyanate (MCA) in 100 ml of deionized water, heat to 90 ° C, and stir at a high speed to form a stable dispersion system. Dilute 3.28 ml of 36.5% concentrated hydrochloric acid with 50 ml of deionized water and slowly add it dropwise , after the feeding is completed, keep the temperature constant, react for 1.5 hours, cool, precipitate, filter, and wash until nearly neutral, and the white powdery solid obtained is uric acid melamine hydrochloride. Disperse an appropriate amount of uric acid melamine hydrochloride in 50ml of water, heat and stir to form a colorless solution, slowly add it dropwise into the montmori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com