Coaxial heterojunction TiO2 nanotube array and preparation method thereof

A nanotube array and coaxial heterojunction technology, which is applied in the field of nanotube array film preparation, can solve the problems of reduced specific surface area and adsorption capacity, clogged nanotubes, etc., and achieves performance improvement, distance reduction, and increased contact area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

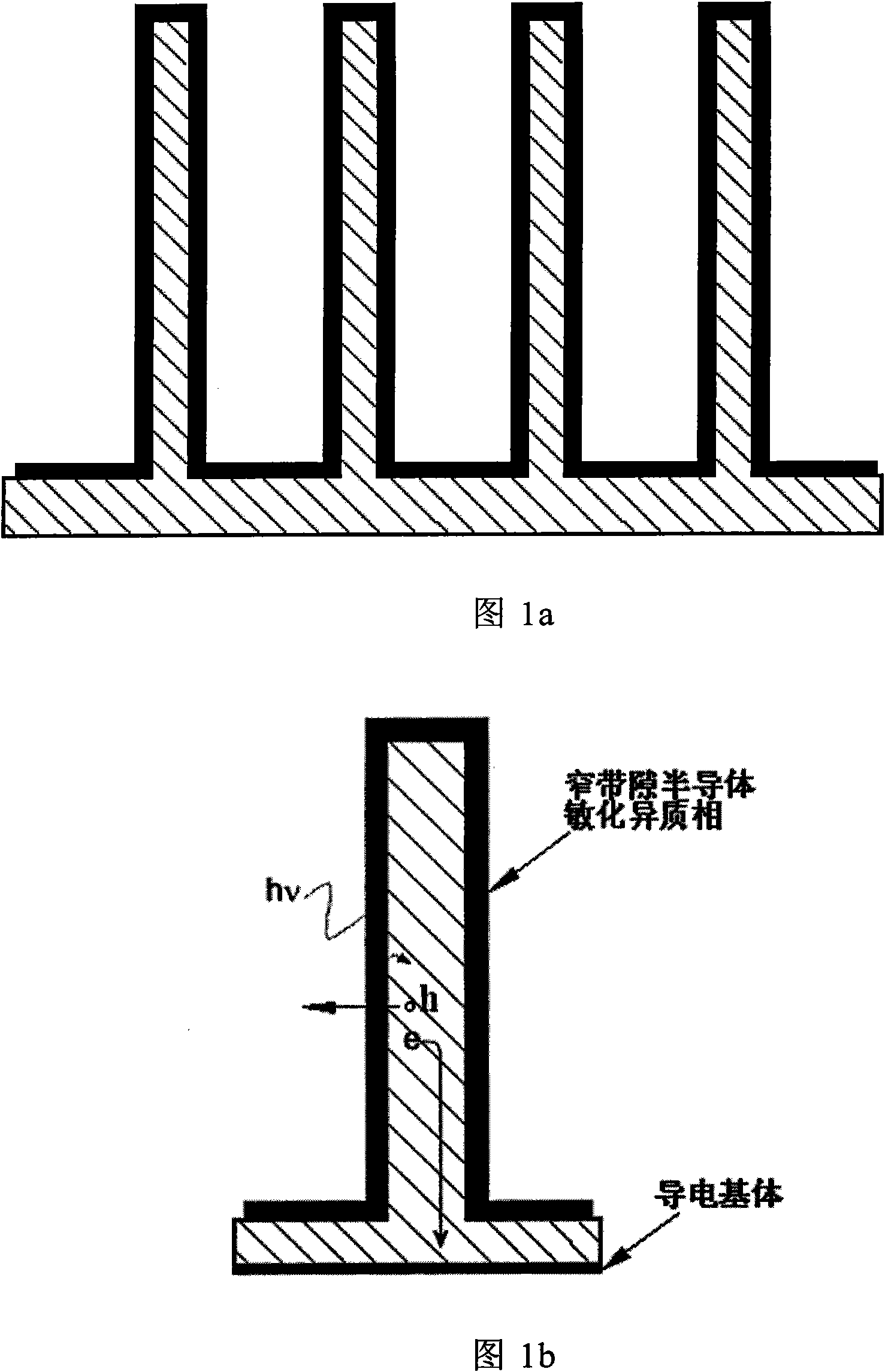

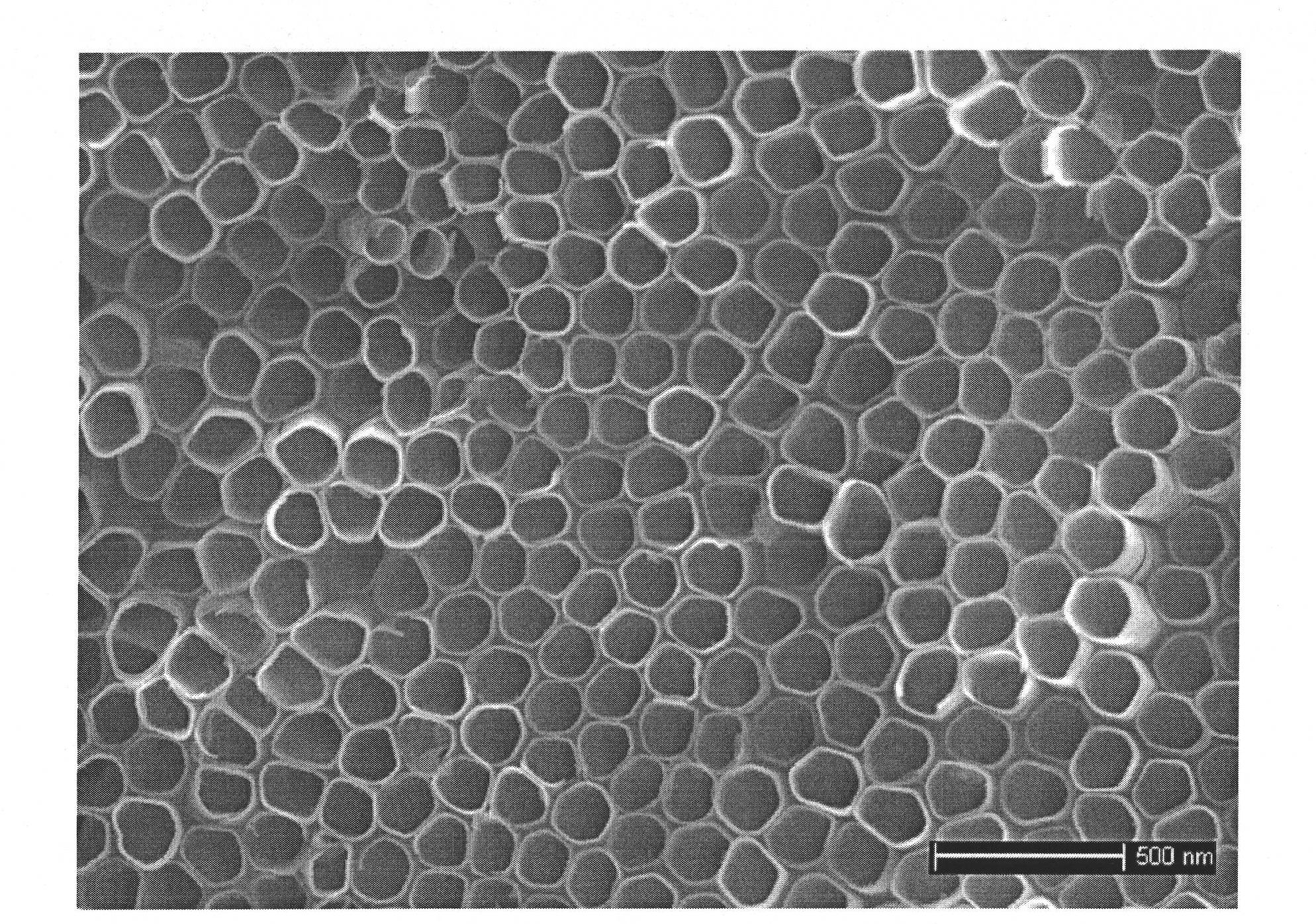

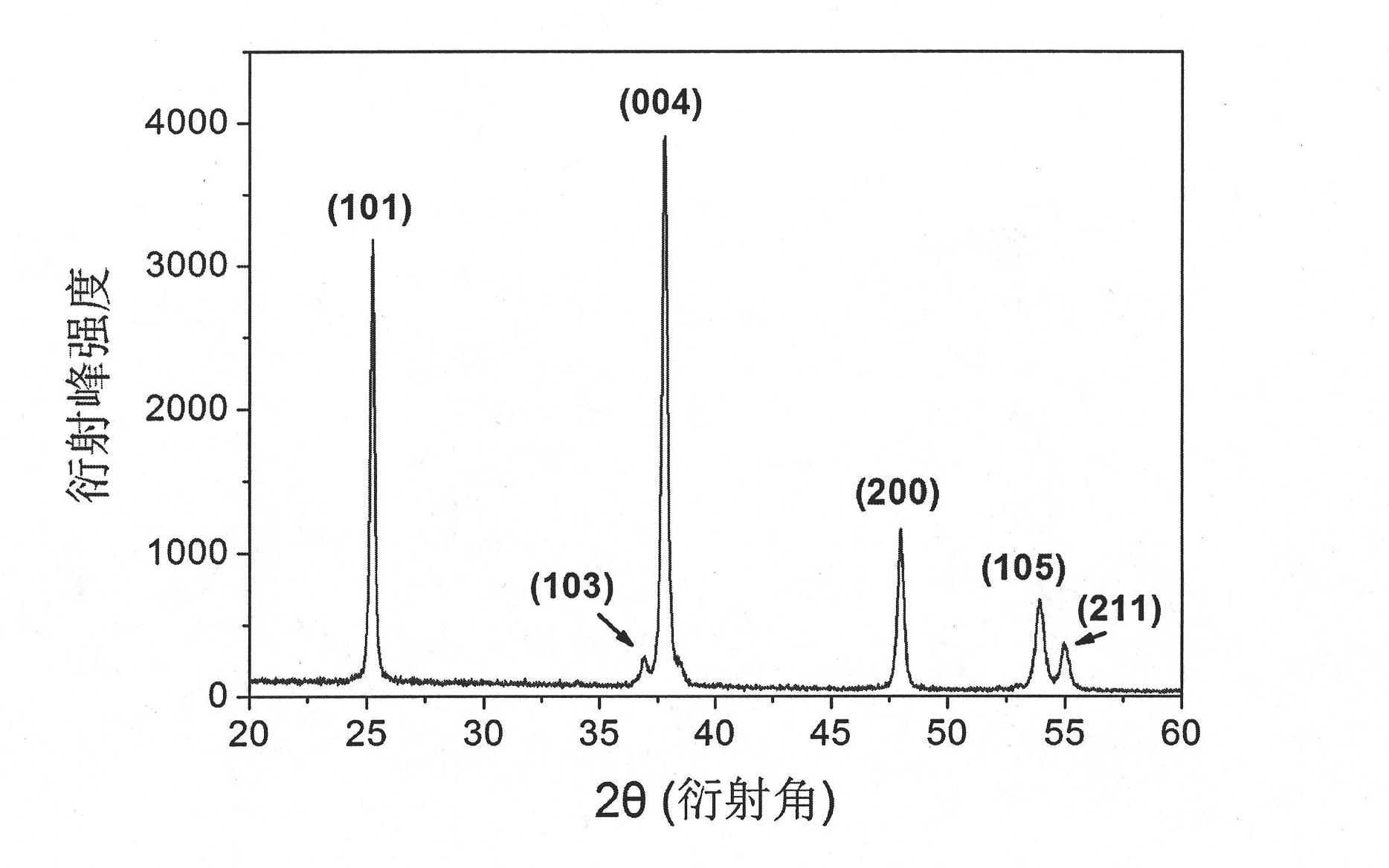

[0049] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0050] The method for preparing coaxial heterojunction nanotube arrays described in the present invention is a new method combining electrochemical deposition technology and atomic layer epitaxy technology, which has the advantages of electrochemical room temperature deposition, low cost and accurate atomic layer epitaxy Advantages of controlling the epitaxial layer. The difference from other electrochemical deposition techniques is that it forms a surface chemically limited growth through an underpotential deposition process, and achieves epitaxial growth by electrodepositing single atomic layers of compound constituent elements. The atomic layer deposition of different elements is carried out in different solutions. , so the deposition conditions (deposition potential, reaction solution concentration, etc.) of each element can be op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com