Advanced treatment process of sludge containing oil

A technology of advanced treatment and sludge, applied in sludge treatment, biological sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of coking operation impact, excessive investment, secondary pollution of waste water and waste residue, etc. To achieve the effect of convenient maintenance and management, simple equipment maintenance and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

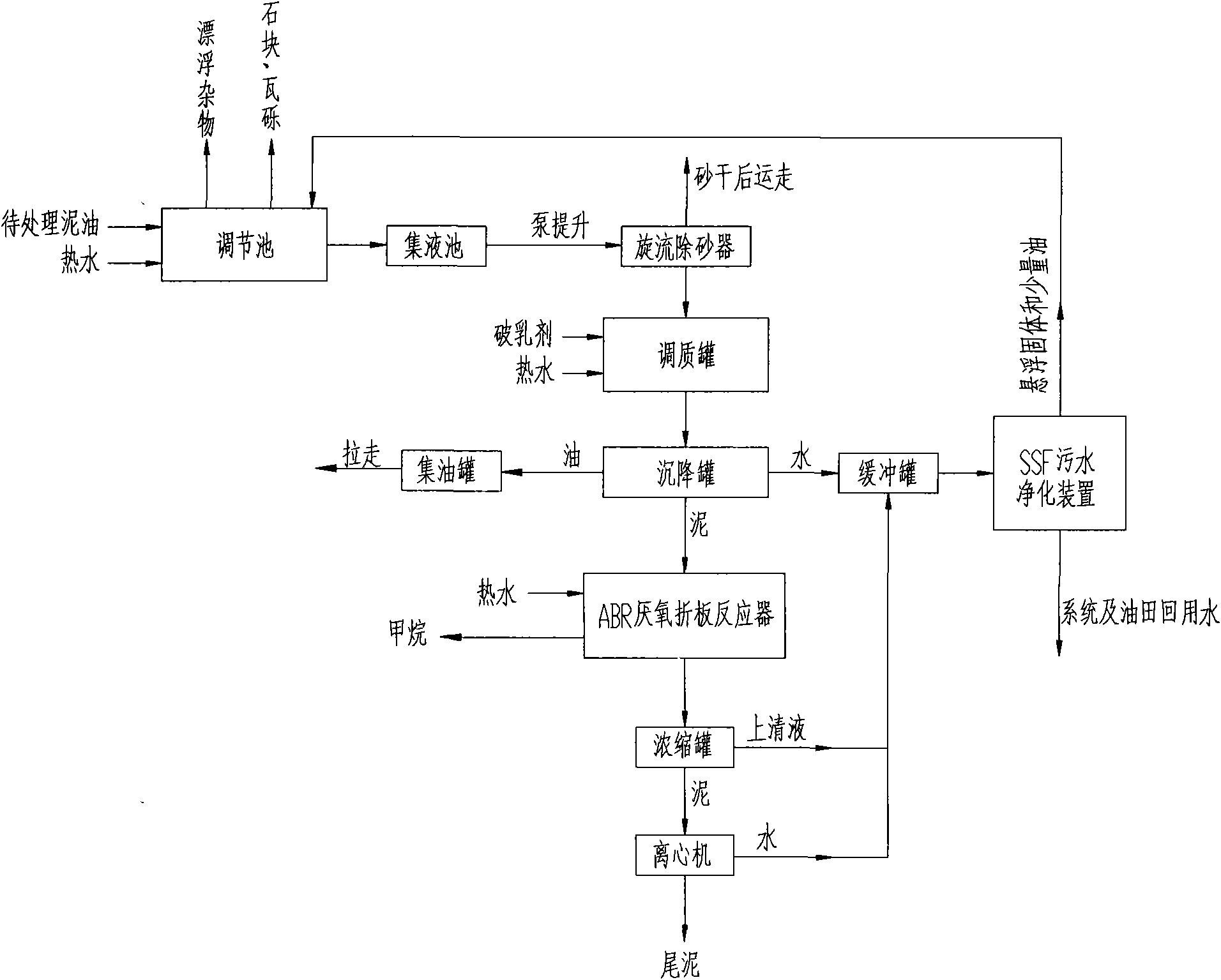

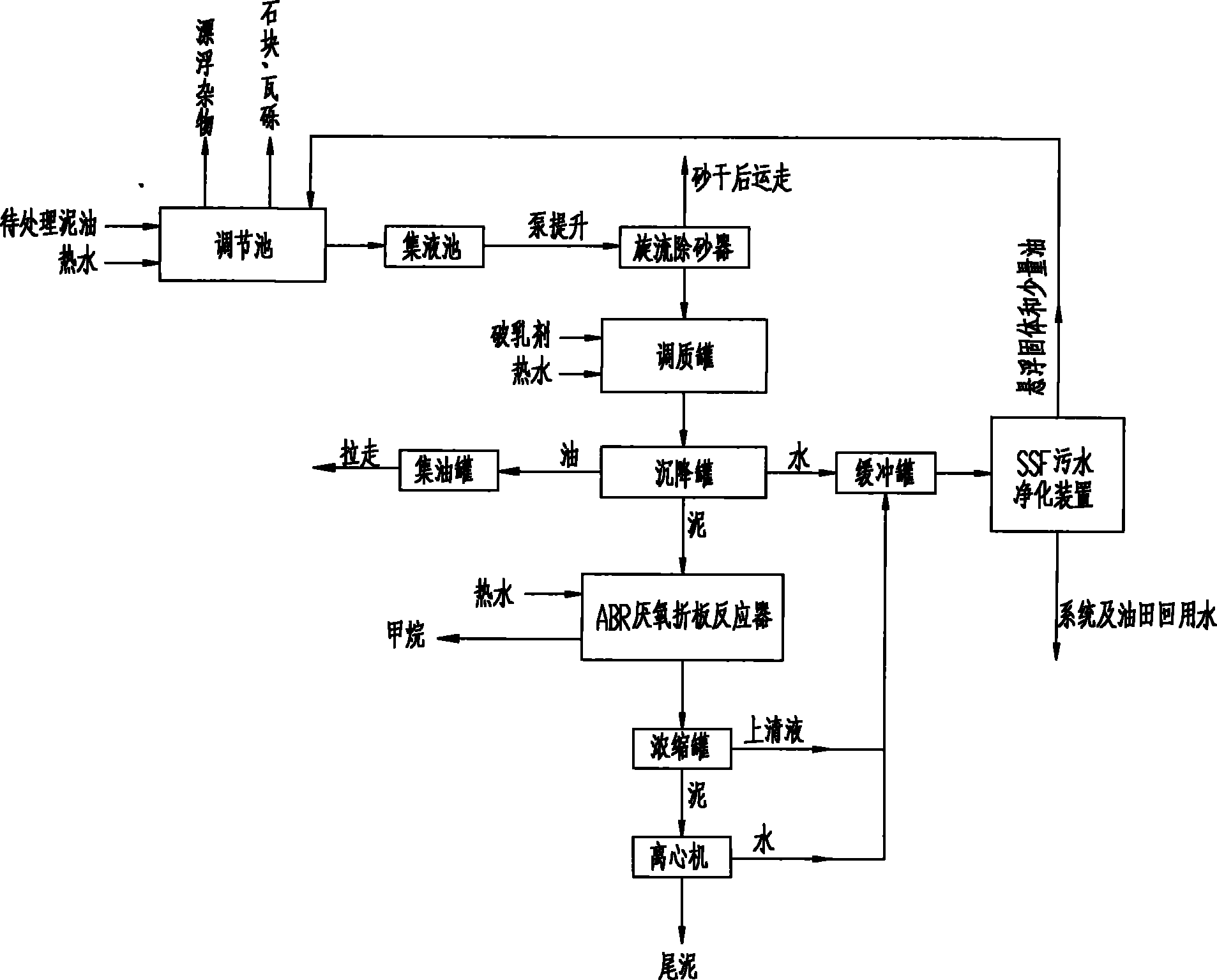

[0036]figure 1 The specific implementation process is given:

[0037] (1) First, dilute and stir the oil sludge in hot water 2.5 times (referring to 2.5 times the design capacity, the same below) in the regulating tank to make it have a certain fluidity, and regularly use the grab bucket to clean the gravel at the bottom of the tank and construction waste and other sundries; let the above-mentioned diluted sludge flow through the grid to remove floating sundries and then enter the sump.

[0038] (2) The sludge water in the liquid collection tank is input into the hydrocyclone by the pump to remove sand, and the discharged sand is air-dried to a certain extent and then transported away;

[0039] (3) Add 2.5 times hot water to the desanded sludge water and the appropriate demulsifier selected for the oil and mix and stir to further dilute and demulsify the sludge, and then enter the conditioning tank, which is equipped with a mixer And the heating coil, after fully stirring and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com