Vanadium-based multiple coating liquid, composite film and preparation method and application thereof

A multi-component composite, coating solution technology, applied in the coating and other directions, can solve the problems of low visible transmittance, difficult to stabilize control, etc., to achieve the effect of high visible light transmission, simple process, and improved visible transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 A method for preparing a vanadium-based composite film with a phase transition temperature of 45°C includes the following steps in sequence:

[0029] (1) Put 18.18g V 2 O 5 Add 100ml of ionized water into a 250ml beaker, add hydrazine hydrate solution dropwise while stirring until a blue transparent solution is obtained. 20 ml of silica sol aged for 3 days with a concentration of 1 mol / liter was added to the blue transparent solution. After aging for 4 hours, a stable vanadium-based multi-element coating solution was prepared.

[0030] (2) The quartz glass is cleaned by standard RCA to remove contaminated organic matter, dust and metal ion impurities on the glass surface. Coating by spin coating, spin coating speed is 500r / min, dry for 10 minutes, then repeat the operation 2 times.

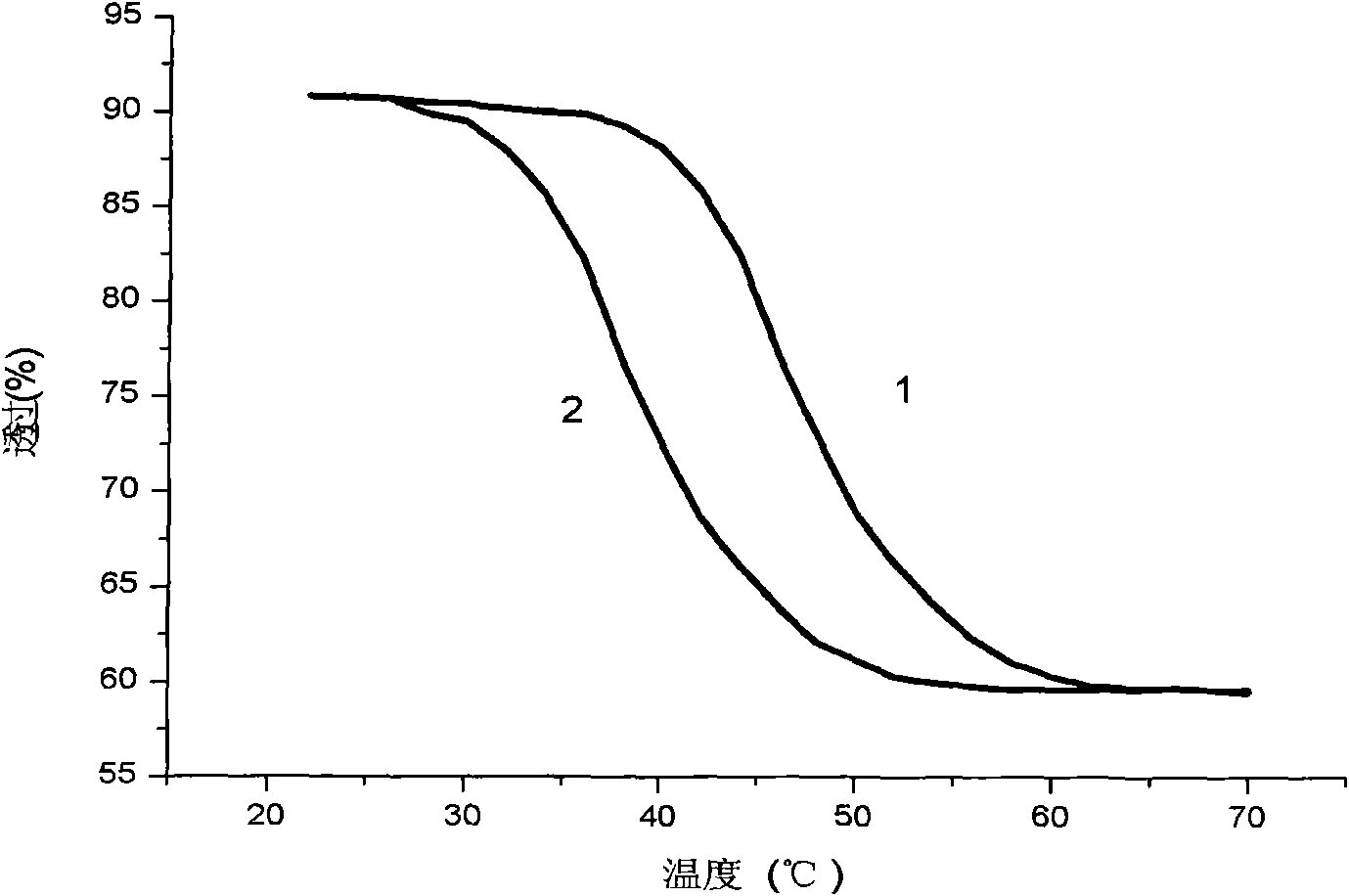

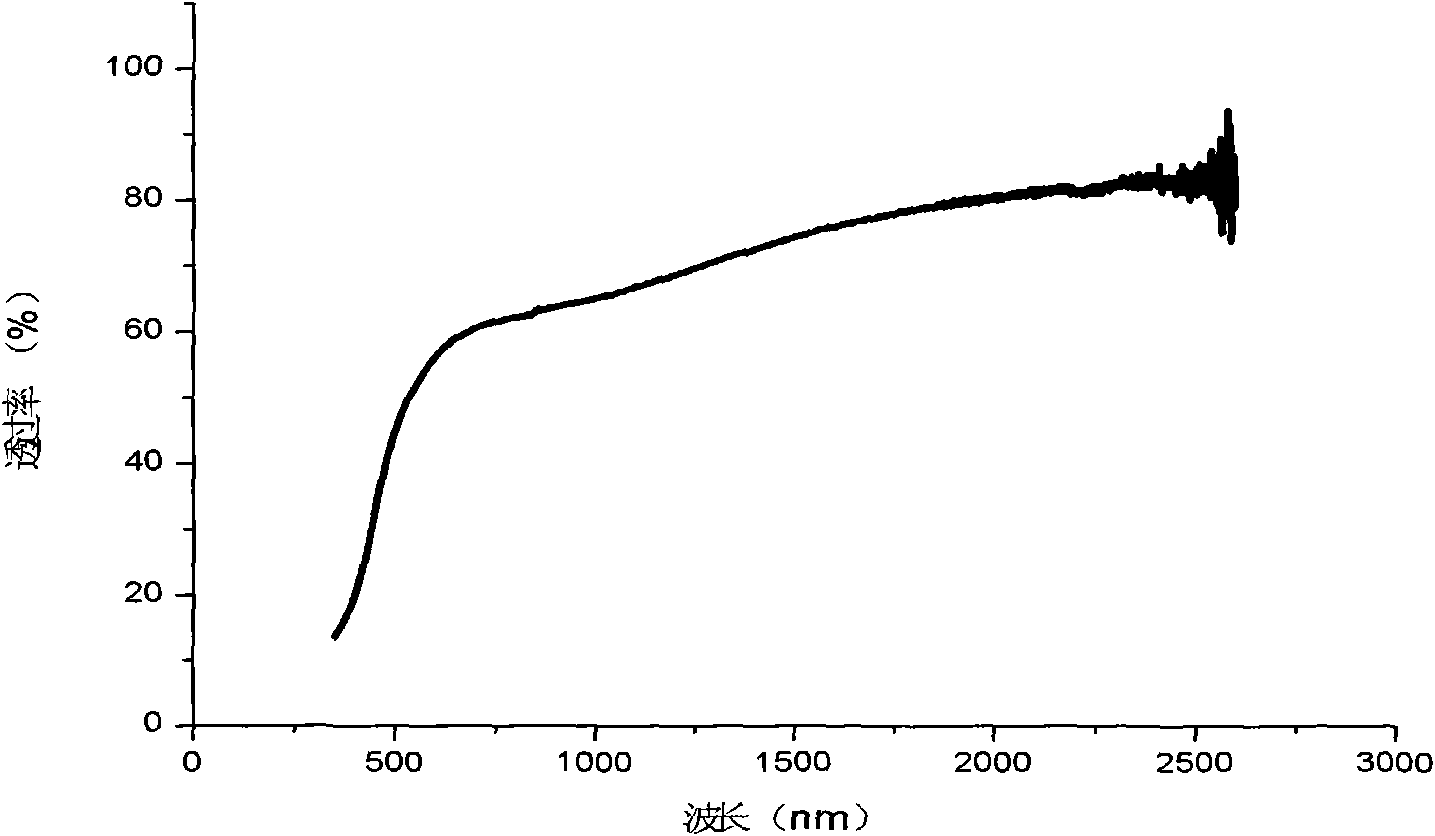

[0031] (3) In a nitrogen atmosphere, keep the temperature at 600°C for 1 hour, and then let the furnace temperature drop naturally to obtain a vanadium oxide-silicon oxide composite fi...

Embodiment 2

[0033] Example 2 A method for preparing a vanadium-based composite film with a phase transition temperature of 75°C includes the following steps in sequence:

[0034] (1) Put 18.18g V 2 O 5 Add 100ml of ionized water into a 250ml beaker, add hydrazine hydrate solution dropwise while stirring until a blue transparent solution is obtained. Add 20 ml of 1 mol / L titanium sol aged for 3 days to the blue transparent solution. After aging for 10 minutes, a stable vanadium-based multi-element coating solution was prepared.

[0035] (2) The quartz glass is cleaned by standard RCA to remove contaminated organic matter, dust and metal ion impurities on the glass surface. Coating by spin coating, spin coating speed is 3000r / min, dry for 10 minutes, then repeat the operation 2 times.

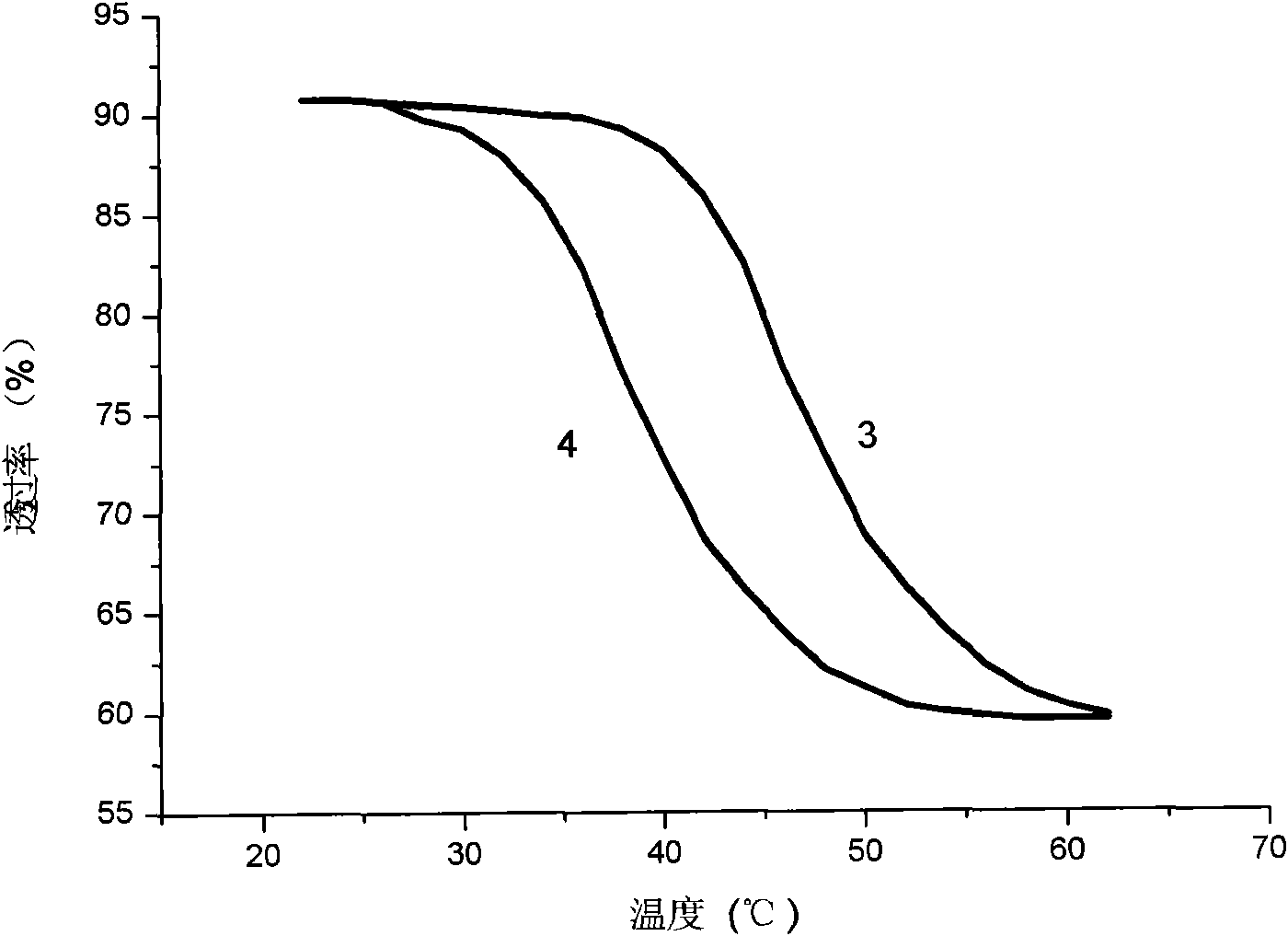

[0036] (3) In a nitrogen atmosphere, keep the temperature at 600°C for 1 hour, and then let the furnace temperature drop naturally to obtain a uniform vanadium-based composite film with a phase transition tempera...

Embodiment 3

[0038] Example 3 A method for preparing a vanadium-based composite film with a phase transition temperature of 100°C includes the following steps in sequence:

[0039] (1) Put 18.18g V 2 O 5 Add 100ml of ionized water into a 250ml beaker, add hydrazine hydrate solution dropwise while stirring until a blue transparent solution is obtained. 13 ml of titanium sol aged for 6 days at 1 mol / L was added to the blue transparent solution. After aging for 30 minutes, a stable vanadium-based multi-element coating solution was prepared.

[0040] (2) The quartz glass is cleaned by standard RCA to remove contaminated organic matter, dust and metal ion impurities on the glass surface. Coating by spin coating, spin coating speed is 15000r / min, dry for 10 minutes, and then repeat the operation twice.

[0041] (3) In a nitrogen atmosphere, keep the temperature at 500°C for 1 hour, and then let the furnace temperature drop naturally to obtain a uniform vanadium-based composite film with a phase trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com