Process method for preparing low residual voltage ZnO varistor ceramic

The technology of a varistor and a process method is applied in the processing field of low-residual-voltage ZnO varistor ceramics, which can solve the problems of inability to meet industrial applications, increase in leakage current density, etc., so as to be suitable for industrial applications and suppress the growth of leakage current. , high-performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

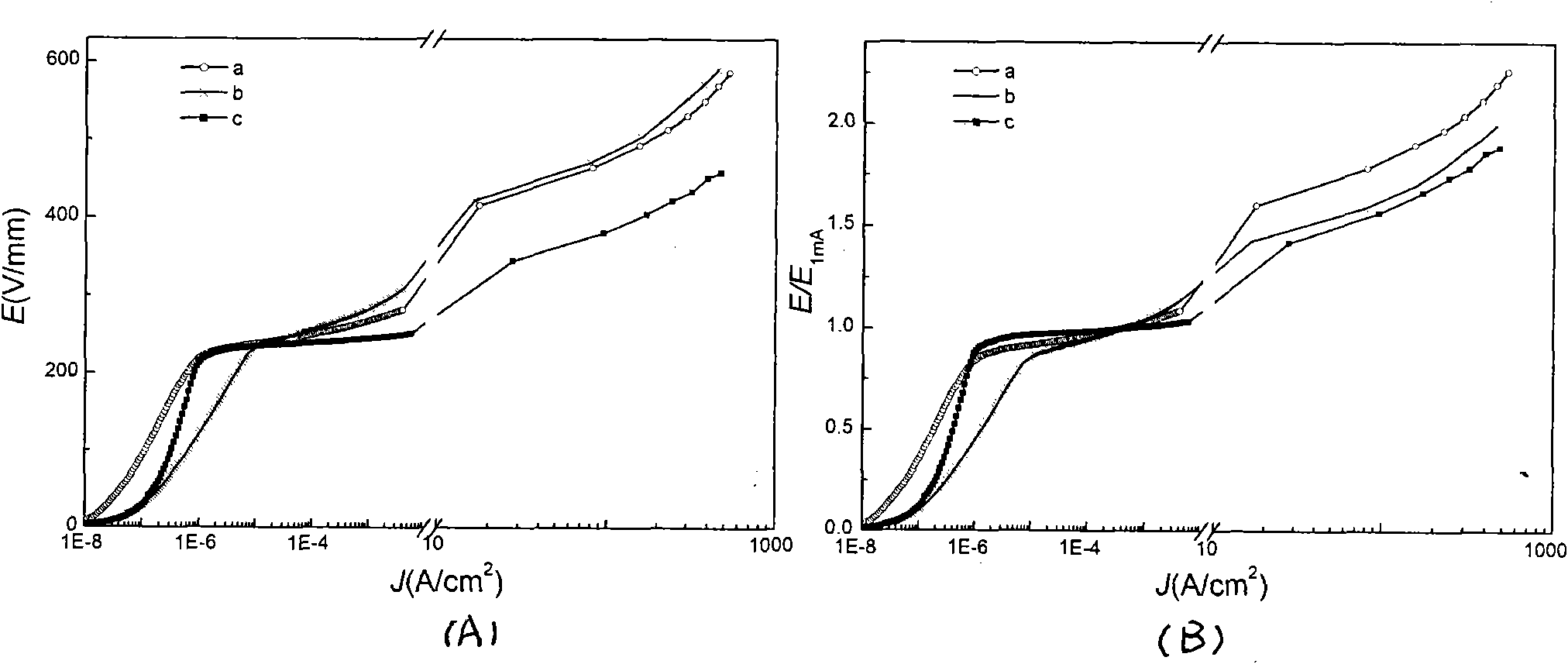

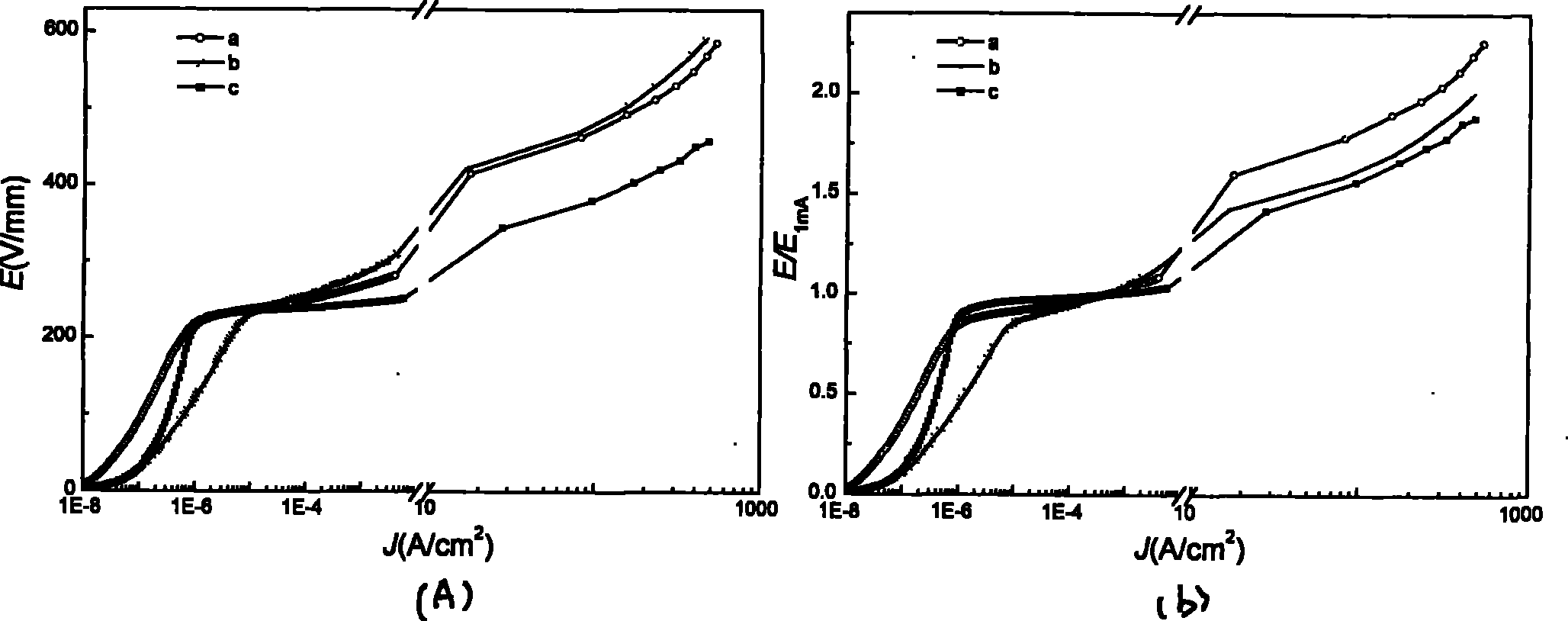

Image

Examples

preparation example Construction

[0017] The preparation method of the present invention is characterized in that the method is based on the preparation technology of low residual voltage ZnO varistor ceramics based on the two-step sintering method and the seed crystal method, and the raw material formula of the preparation method includes: ZnO (92.7-97mol%) 、 Bi 2 o 3 (0.4-0.9mol%), MnO 2 (0.4-0.7mol%), Sb 2 o 3 (0.5-1.5mol%), Co 2 o 3 (0.5-1.5mol%), SiO 2 (0.8-1.7mol%), Al(NO 3 ) 3 9H 2 O (0.1-0.4mol%) and Cr 2 o 3 (0.3-0.7mol%); the method comprises the following steps:

[0018] 1) Preparation of the seed crystal and the first step of sintering:

[0019] (11) Using 20%-50% of ZnO and 0%-20% of Bi in the raw material formula 2 o 3 and all Al(NO 3 ) 3 9H 2 O; be placed in a ball mill tank with deionized water or alcohol added, ball milled for 8-12 hours, and then dried as a seed crystal raw material;

[0020] (12) Put the dried seed crystal raw material into a high-temperature electric furna...

Embodiment 1

[0027] The raw material formula of the present embodiment is as follows:

[0028] The low residual voltage ZnO varistor ceramic raw material is prepared according to the following ratio: ZnO (94.8mol%), Bi 2 o 3 (0.7mol%), MnO 2 (0.5mol%), Sb 2 o 3 (1mol%), Co 2 o 3 (1mol%), SiO 2 (1.25mol%), Al(NO 3 ) 3 9H 2 O (0.25mol%) and Cr 2 o 3 (0.5mol%); The method of the present embodiment comprises the following steps:

[0029] 1) Preparation of the seed crystal and the first step of sintering:

[0030] (11) Adopt 25% ZnO and all Al(NO 3 ) 3 9H 2 0; be placed in the ball mill tank that adds deionized water for 10 hours, and then dry as the seed crystal raw material;

[0031] (12) Put the dried seed crystal raw material into a high-temperature electric furnace, pre-burn it at 1300°C for 4 hours in the first step to form a hard block of seed crystal, and cool it to room temperature with the furnace;

[0032] (13) After pulverizing the sintered hard block of seed crystal,...

Embodiment 2

[0044] The raw material formula of the present embodiment is as follows:

[0045] The low residual voltage ZnO varistor ceramic raw material is prepared according to the following ratio: ZnO (92.7mol%), Bi 2 o 3 (0.9mol%), MnO 2 (0.7mol%), Sb 2 o 3 (1.5mol%), Co 2 o 3 (1.5mol%), SiO 2 (1.7mol%), Al(NO 3 ) 3 9H 2 O (0.4mol%) and Cr 2 o 3 (0.7mol%); The method of the present embodiment comprises the following steps:

[0046] 1) Preparation of the seed crystal and the first step of sintering:

[0047] (11) Using 25% ZnO and 25% Bi in the raw material formula 2 o 3 and all Al(NO 3 ) 3 9H 2 0; be placed in the ball mill tank that adds deionized water for 12 hours, and then dry as the seed crystal raw material;

[0048] (12) Put the dried seed crystal raw material into a high-temperature electric furnace, pre-fire the first step at 1300° C. for 6 hours to form a hard block of seed crystal, and cool to normal temperature with the furnace;

[0049] (13) After pulver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Voltage gradient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com