Method for separating agricus bisporus polysaccharides from agricus bisporus and determining method thereof

A technology of Agaricus bisporus and Agaricus bisporus, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of low efficiency, long time, high processing temperature, etc., and achieve the effects of low energy consumption, improved extraction rate and yield, and rapid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

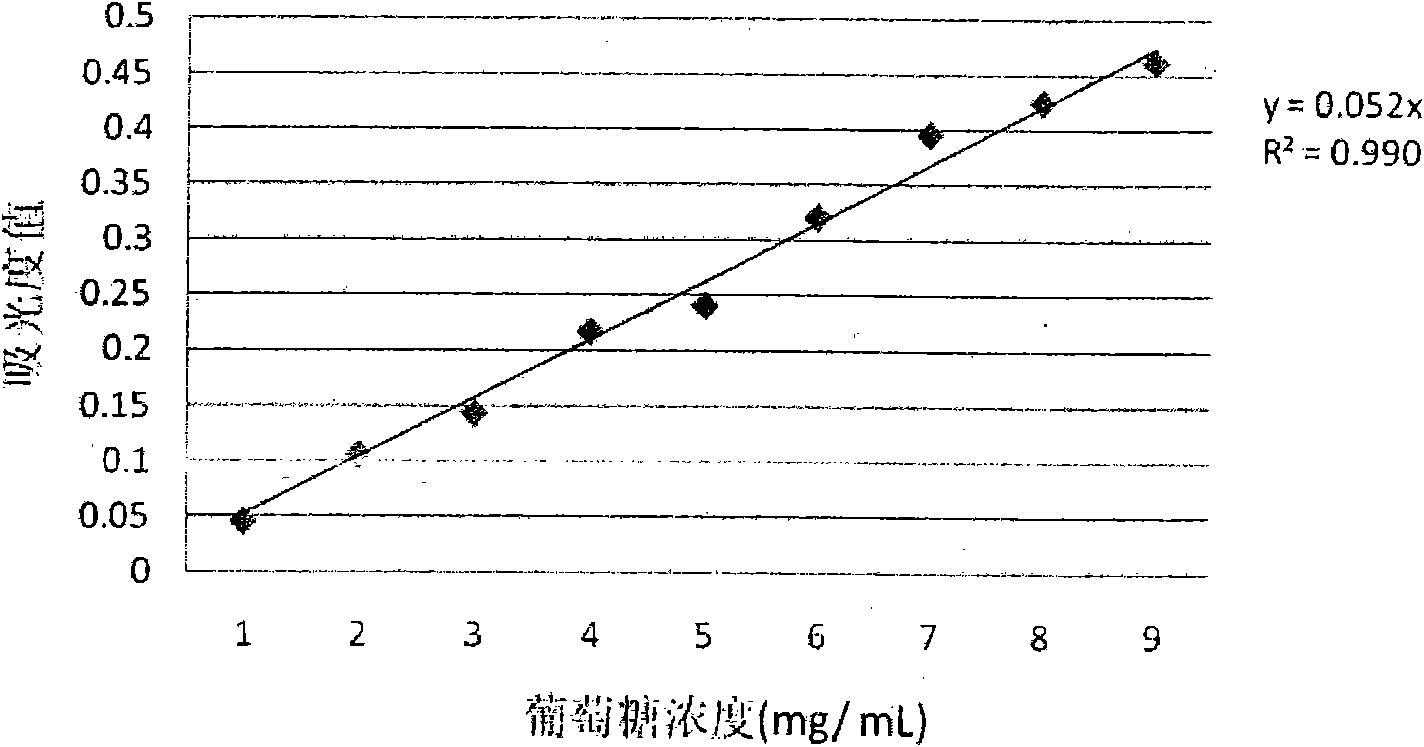

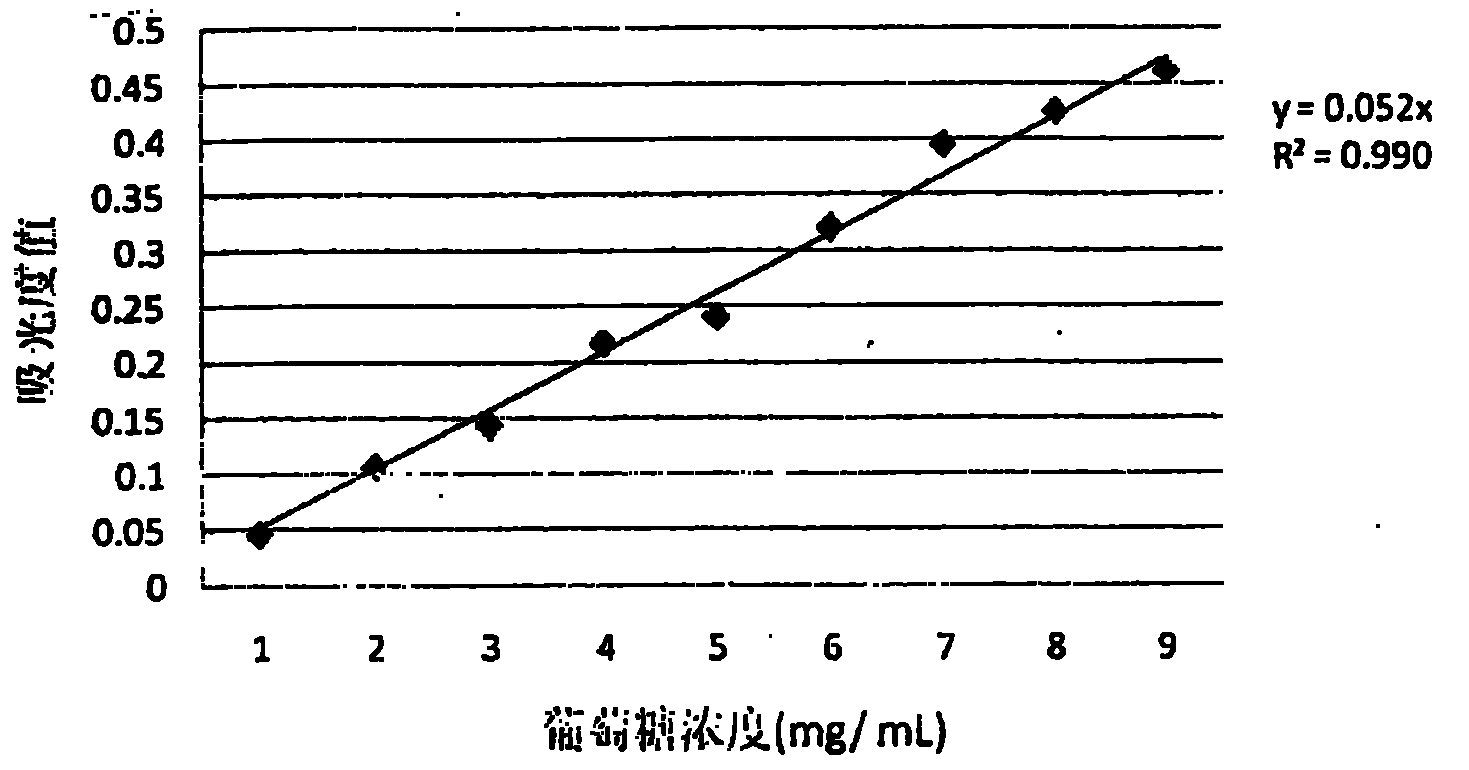

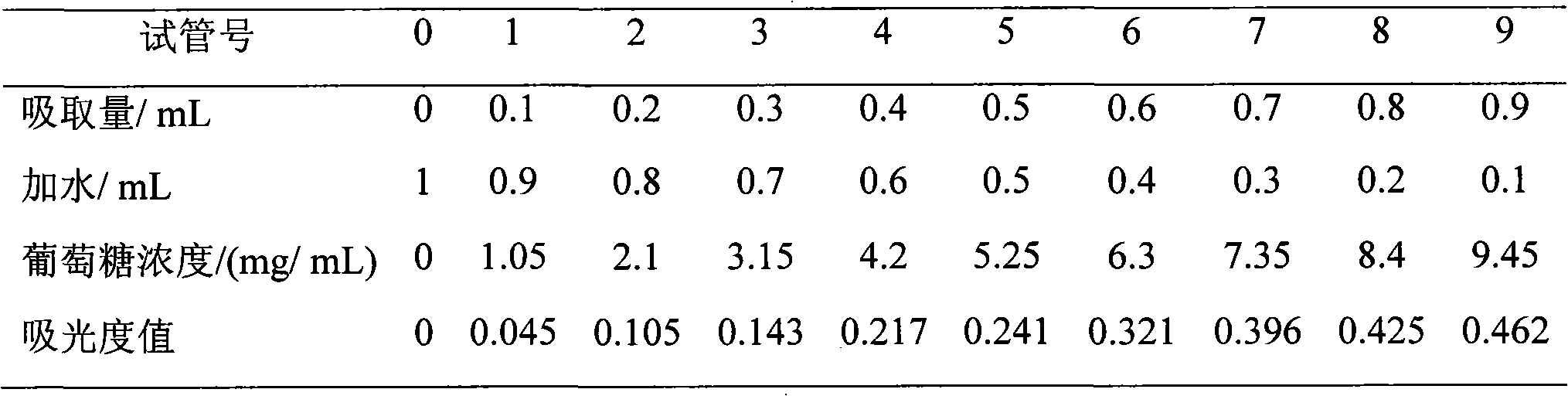

Examples

Embodiment Construction

[0047] A method for isolating Agaricus bisporus polysaccharide from Agaricus bisporus The specific scheme created by the present invention

[0048] 1 Experimental materials, reagents and equipment

[0049] Fresh Agaricus bisporus, phenol, concentrated sulfuric acid, glucose, (NH 4 ) 2 SO 4 , polyethylene glycol (PEG) 6000, distilled water.

[0050] 10mL centrifuge tube, 50mL centrifuge tube, vacuum freeze dryer, centrifuge, UV-722 UV-visible spectrophotometer, analytical balance.

[0051] 2 Experimental methods and steps

[0052] (1) Pretreatment of experimental materials: vacuum freeze-dry fresh Agaricus bisporus for 24 hours.

[0053] (2) Extraction of crude polysaccharides in hot water: crush the dried Agaricus bisporus, weigh two grams, put it in a stainless steel or glass container, add 200mL of distilled water, boil on high heat, keep it on low heat for 1 hour, centrifuge to take the supernatant, and precipitate Put it back into the heating equipment and add 100mL ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com