Method for preparing metal, metallic oxide or metallic hydroxide and carbon nano tube composite

A technology of carbon nanotubes and hydroxides, which is applied in the field of metal oxides, metal hydroxide/carbon nanotube composite materials, and metal preparation, and can solve the problems of large particle size, poor loading effect, and low loading capacity. To achieve the effect of mild reaction conditions, short reaction time and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, preparation platinum / multi-walled carbon nanotube nanocomposite material

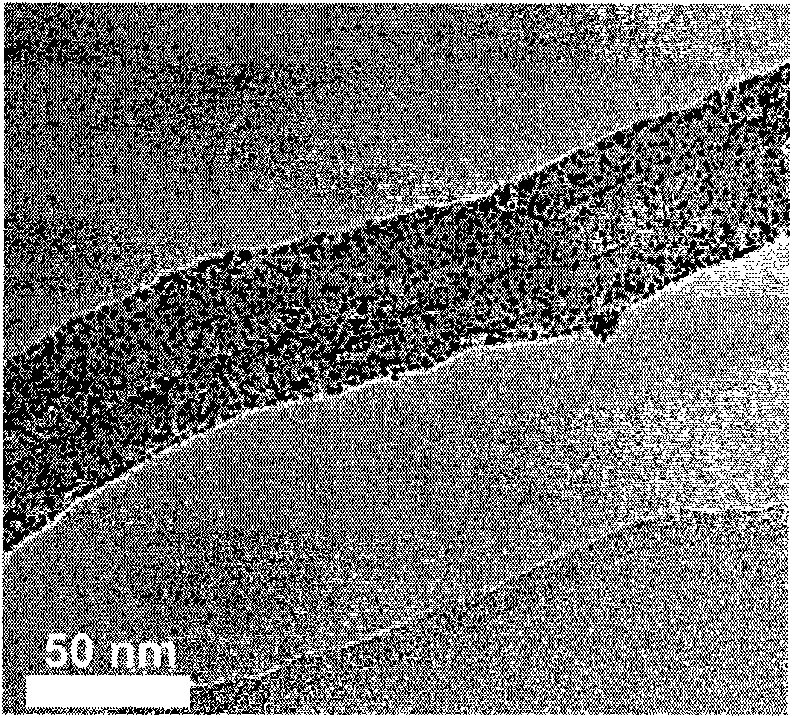

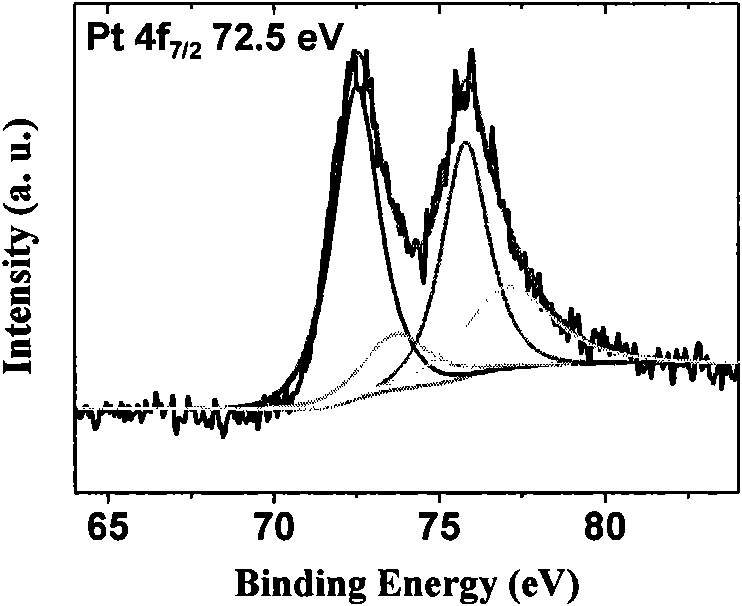

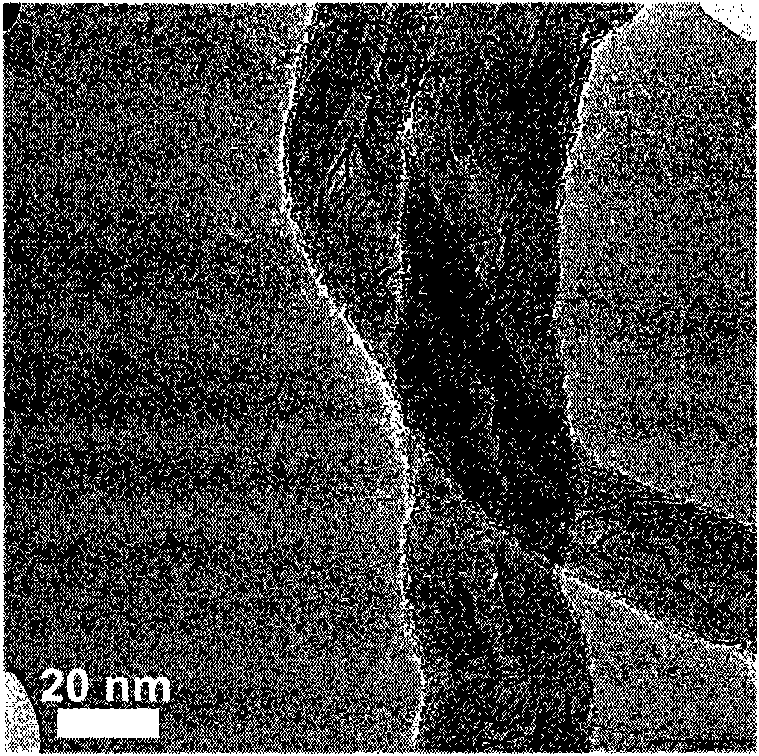

[0030] 1 mg of multi-walled carbon tubes with a diameter of 40-60nm were added to 20 ml of ethanol, ultrasonically dispersed in an ice-water bath for 2 minutes, and 1 ml of chloroplatinic acid ethanol solution with a concentration of 1.0 mg / ml was added to the dispersion; Under the action of ultrasound, 1 ml of 0.36 mg / ml sodium borohydride ethanol solution was slowly added dropwise to obtain a platinum / multi-walled carbon nanotube composite material with a platinum loading of 27.4 wt%. The ultrasonic energy used in this method is 500W, and the reaction temperature is 0°C. The transmission electron microscope photo of the obtained material is shown in figure 1 (microscope model JEM-2011, accelerating voltage 200kV). It can be seen from the figure that the platinum particles are evenly loaded on the surface of the carbon tubes with a narrow size distribution and an average diameter...

Embodiment 2

[0031] Embodiment 2, preparation platinum / multi-walled carbon nanotube nanocomposite material

[0032] 1 milligram of multi-walled carbon tubes with a diameter of 40-60 nm was added to 20 milliliters of ethanol, ultrasonically dispersed in an ice-water bath for 2 minutes, and 1 milliliter concentration of 0.14 mg / ml chloroplatinic acid ethanol solution was added to the dispersion; Under the action of ultrasound, 1 ml of 0.05 mg / ml sodium borohydride ethanol solution was slowly added dropwise to obtain a platinum / multi-walled carbon nanotube composite material with a platinum loading of 5 wt%. The ultrasonic energy used in this method is 500W, and the reaction temperature is 0°C. Transmission electron microscope analysis shows that platinum particles are uniformly loaded on the surface of carbon tubes, and its size is 1.9nm.

Embodiment 3

[0033] Embodiment 3, preparation platinum / multi-walled carbon nanotube nanocomposite material

[0034] 1 milligram of multi-walled carbon tubes with a diameter of 40-60 nm was added to 20 milliliters of ethanol, ultrasonically dispersed in an ice-water bath for 2 minutes, and 1 milliliter of 0.29 mg / ml chloroplatinic acid ethanol solution was added to the dispersion; Under the action of ultrasound, 1 ml of 0.1 mg / ml sodium borohydride ethanol solution was slowly added dropwise to obtain a platinum / multi-walled carbon nanotube composite material with a platinum loading of 10 wt%. The ultrasonic energy used in this method is 500W, and the reaction temperature is 0°C. Transmission electron microscopy analysis shows that platinum particles are uniformly loaded on the surface of carbon tubes, and its size is 2.0nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com