Spherical silicon dioxide hollow material and preparation method thereof

A spherical silica and hollow technology, which is applied in the manufacture of silica, silicon oxide, and nanostructures, can solve the problems of long reaction time and achieve the effects of simple operation, easy-to-obtain non-toxic raw materials, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Cholic acid crystals were purified by ethanol recrystallization.

[0021] At 25°C, add 0.2g of commercially available ammonia water (25%) into 32ml of water to make an aqueous ammonia solution, add 0.5g of cholic acid crystals to it, and after 2 hours, the cholic acid is completely dissolved to form a clear solution, pH 9; 0.29g3 - Aminopropyltriethoxysilane was mixed with 0.27 g of ethyl orthosilicate, added to the above-prepared solution, stirred and reacted for 0.5 hour to form a milky white emulsion-like homogeneous system. The above reactant system was left to mature at 80° C. for 15 hours. The obtained product was filtered, the filter cake was washed three times with water and 95% ethanol respectively, and dried in a drying oven at 60° C. for 6 hours to obtain a white powdery solid.

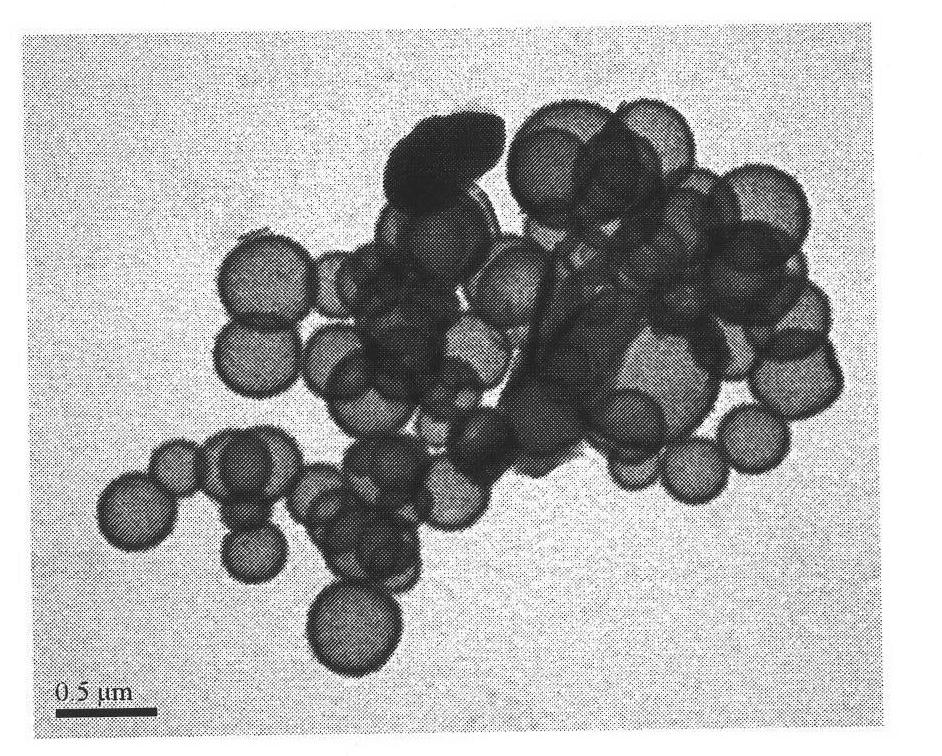

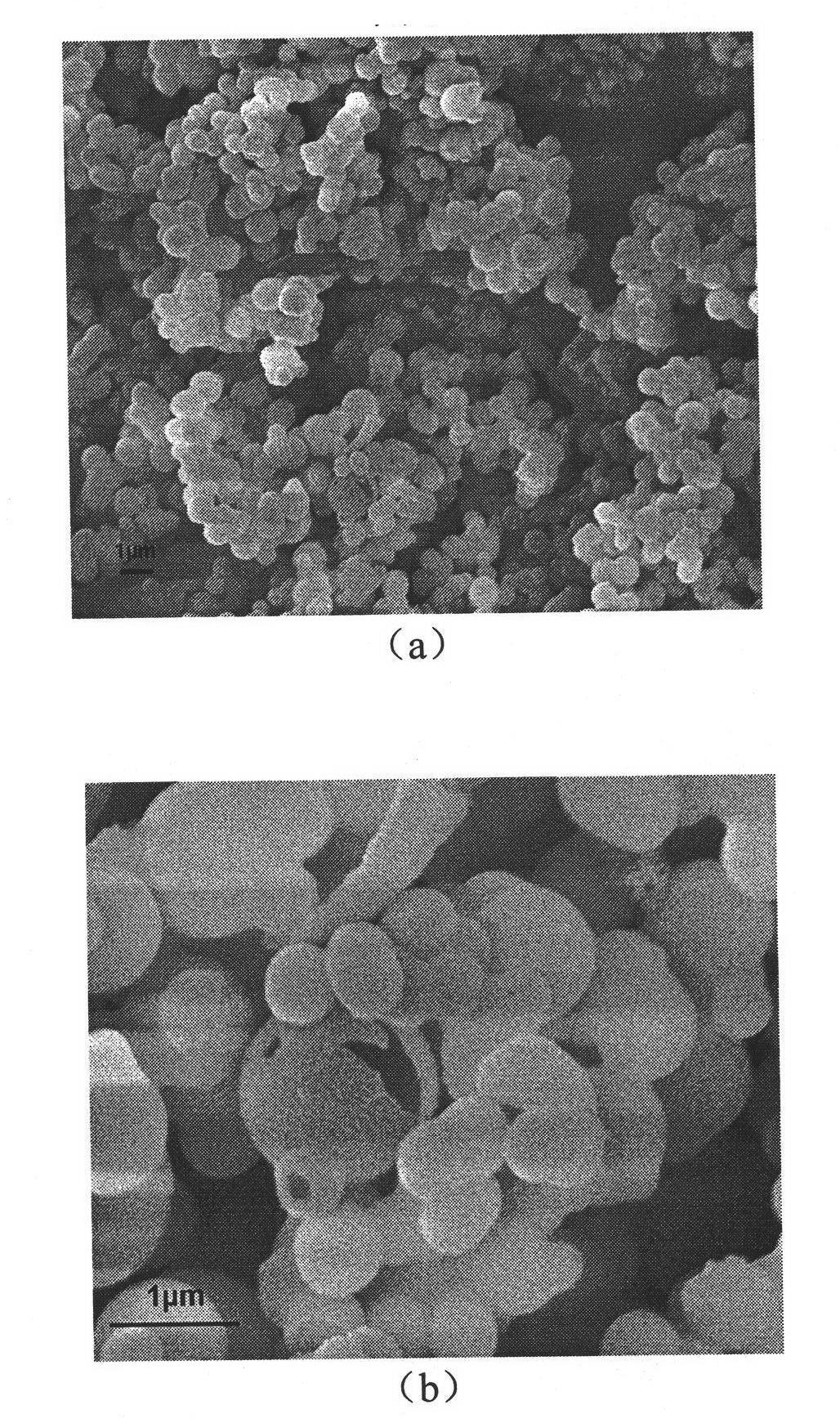

[0022] figure 1 The TEM photos of the spherical silica hollow material prepared in Example 1 are given. TEM detection shows that the obtained product has a spherical hollow struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com