Preparation method of blue/purple long-distance triggered LED (Light Emitting Diode) white-light emitting illumination material

A technology for remote excitation and luminescent materials, applied in luminescent materials, energy-saving lighting, chemical instruments and methods, etc., can solve the problems of decreased luminous efficiency of phosphors, limited application range of phosphors, color drift of white LEDs, etc., and achieves long service life , reduced dosage, and non-toxic raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Glass pretreatment: Soak a 10cm×10cm square glass piece in an aqueous solution with a washing powder content of 4g / L, and ultrasonically clean it for 30 minutes, take out the glass piece, wash it with deionized water for 2 minutes, and then put it in the oven medium, dry at 120°C for 15 minutes, and set aside;

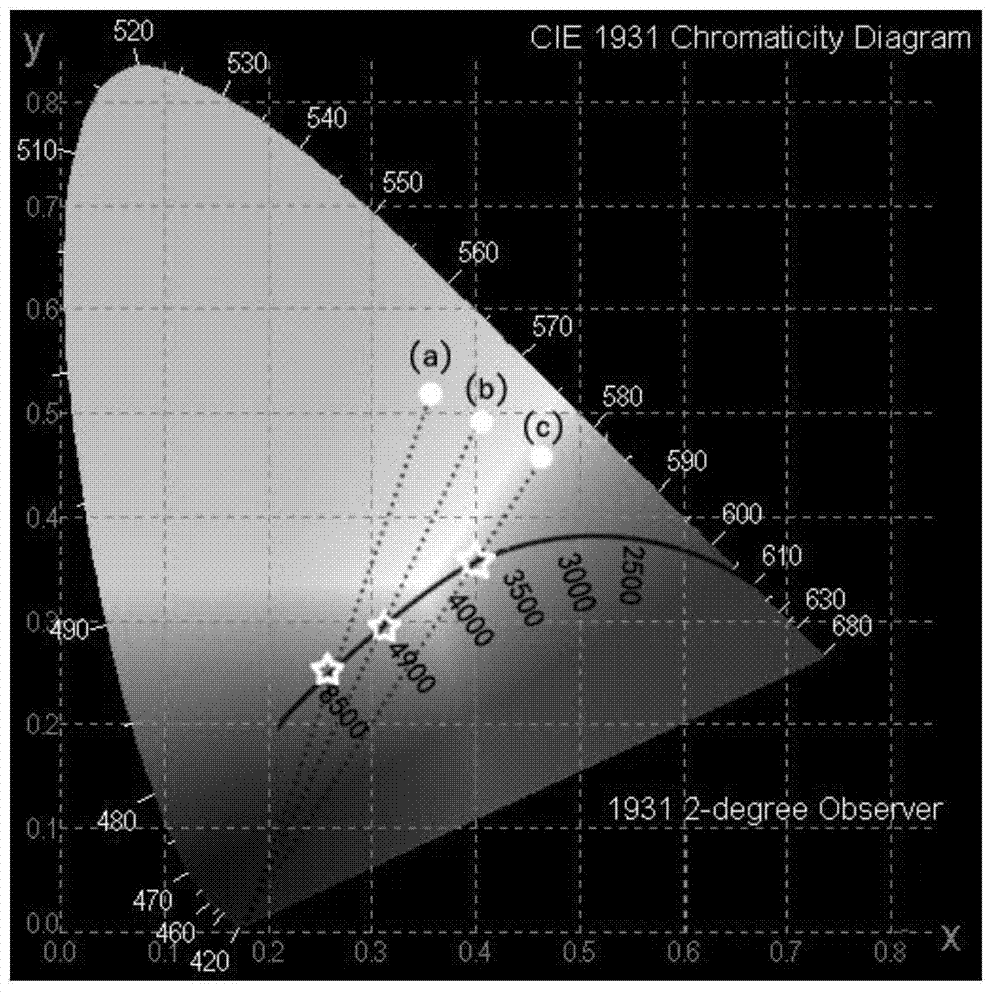

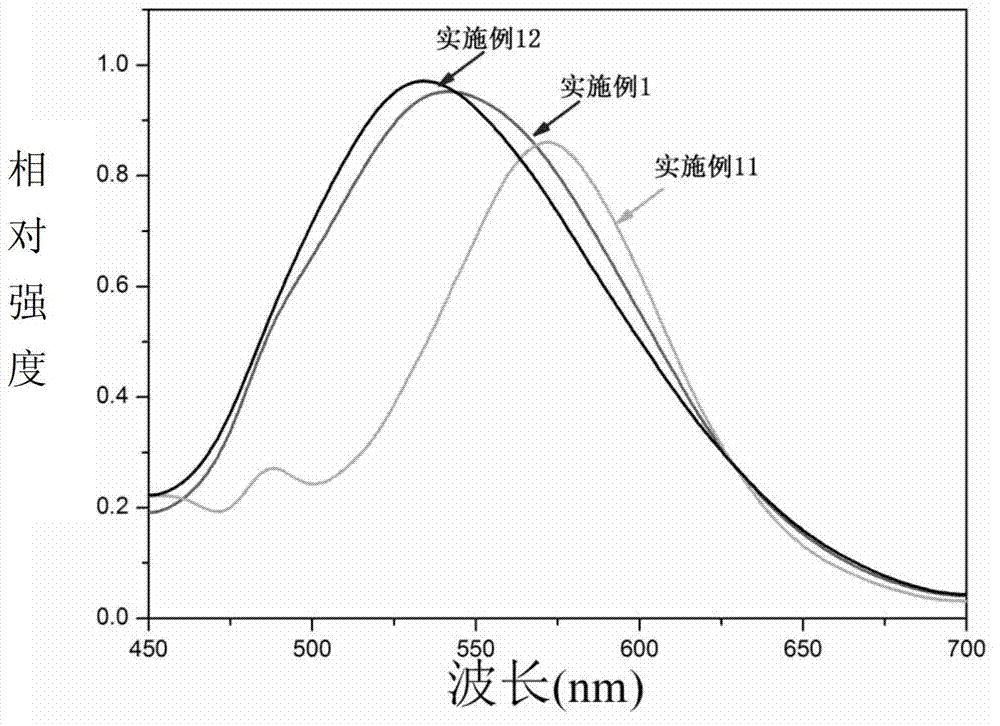

[0029] Pour 6.0g of liquid polyurethane into a 50mL beaker, then add 2.0g of butyl acetate and 0.05mL of defoamer (the content of polydimethylsiloxane is 0.015mg), and finally add Sr 2.97 al 0.025 Si 0.975 o 5 : Ce 3+ 0.025 , Eu 2+ 0.005 Phosphor powder 2.0g, stir for 1 hour; drop-coat the stirred paste substance on the pretreated glass sheet, the coating thickness is 0.3-0.4mm; put the coated glass sheet in an oven to dry at 40°C The blue / purple light remote excitation LED white light lighting luminescent material can be obtained by drying under the same conditions for 12 hours. Figure 5 It is a comparison diagram of the fluorescence intensity between ...

Embodiment 2

[0031] The addition amount of liquid polyurethane in Example 1 was adjusted to 6.5g, the addition amount of butyl acetate was adjusted to 1.5g, and the others were kept unchanged, and the blue / violet light remote excitation LED white light lighting luminescent material was obtained.

Embodiment 3

[0033] The addition amount of liquid polyurethane in Example 1 was adjusted to 7.0 g, the addition amount of butyl acetate was adjusted to 1.0 g, and the others were kept unchanged to obtain a blue / purple light remote excitation LED white light lighting luminescent material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com