Multifunctional anti-leakage shrinkage type concrete surface layer reinforcer

A multi-functional, concrete technology, applied in the field of building materials, can solve the problems of single effect of surface strengthening agent, inconvenient construction, less dosage, etc., and achieve significant shrinkage reduction performance, improve surface strength, and small dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

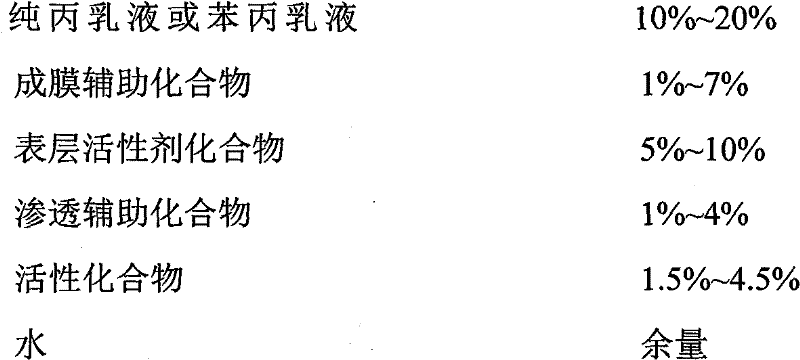

[0032] Mix the following components by weight ratio and stir evenly to obtain the multifunctional anti-seepage and shrinkage-reducing concrete surface strengthening agent of the present invention:

[0033] High Molecular Polymer 10%

[0034] Film-forming auxiliary compound 2%

[0035] Surfactant compound 6.5%

[0036] Penetration Aid Compound 1.5%

[0037] active compound 3%

[0038] Water 77%

[0039]Among them, the high molecular polymer is pure acrylic emulsion; the film-forming auxiliary compound is diethylene glycol monomethyl ether; the surfactant compound is alkyl polyethylene glycol ether; the penetration auxiliary compound is organosilane; the active compound is nano silicic acid sodium.

Embodiment 2

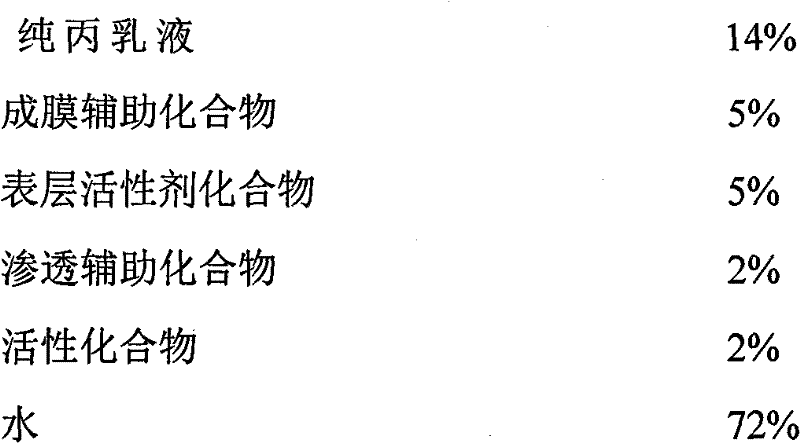

[0041] Mix the following components by weight ratio and stir evenly to obtain the multifunctional anti-seepage and shrinkage-reducing concrete surface strengthening agent of the present invention:

[0042] Polymer 17%

[0043] Film-forming auxiliary compound 4%

[0044] Surfactant Compound 8%

[0045] Penetration Aid Compound 2%

[0046] active compound 4%

[0047] water 75%

[0048] Wherein, the high molecular polymer is styrene-acrylic emulsion; the film-forming auxiliary compound is dodecyl alcohol ester; the surfactant compound is alkaryl polyether alcohol; the permeation auxiliary compound is organosilane; and the active compound is sodium polyacrylate.

Embodiment 3

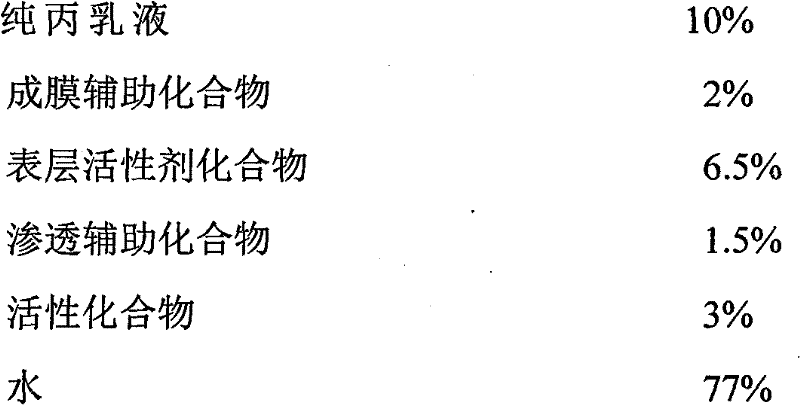

[0050] The components and weight percentages of a multifunctional anti-seepage and shrinkage-reducing concrete surface layer strengthening agent are:

[0051] Polymer 14%

[0052] Film-forming auxiliary compound 5%

[0053] Surfactant Compound 5%

[0054] Penetration Aid Compound 2%

[0055] active compound 2%

[0056] Water 72%

[0057] Among them, the high molecular polymer is pure acrylic emulsion; the film-forming auxiliary compound is dodecyl alcohol ester; the surfactant compound is alkaryl polyether alcohol; the penetration auxiliary compound is methyl methacrylate; the active compound is nano-scale silicon Sodium acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com