Normal temperature extra soft adhesive for externally repairing side edge scratches of retreaded tire and repairing process

A tire tire and normal temperature technology, which is applied in the field of normal temperature special soft rubber for external repair of retreaded tire sidewall damage and repair technology, can solve the problems of inconvenient repair operation, difficult repair operation, low production efficiency, etc., and achieve easy repair and filling Glue operation, repair station is easy, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

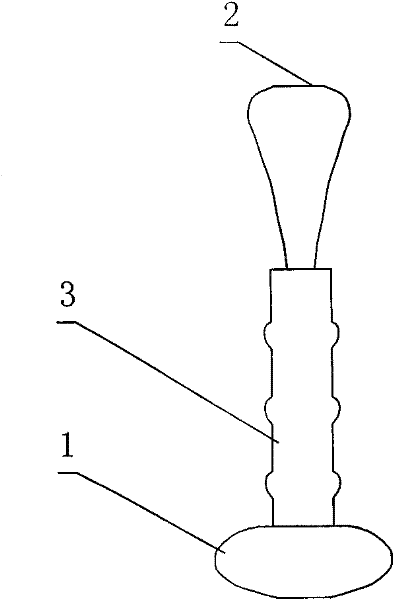

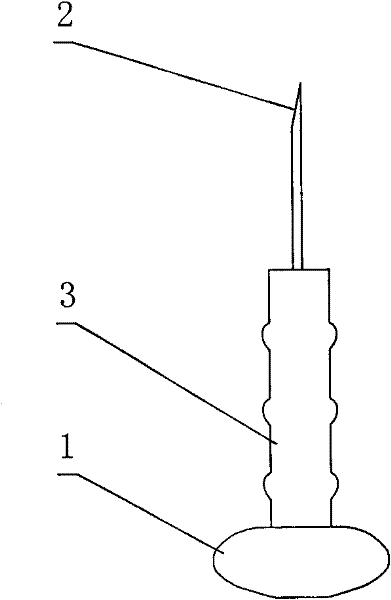

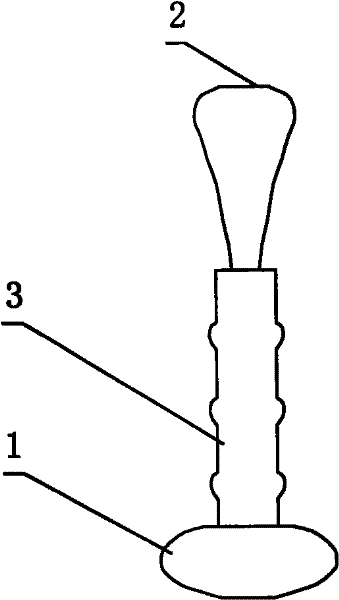

Image

Examples

Embodiment Construction

[0021] Special soft rubber at room temperature for repairing sidewall damage of retreaded tires, composed of the following raw materials in parts by weight: natural standard rubber: 80, butadiene rubber 9000: 20, CaCO 3 : 100, carbon black N754: 10, zinc oxide 99.5% (zinc oxide with a purity of 99.5%): 5, stearic acid: 3, antioxidant 4010: 1, antioxidant RD: 1, antioxidant DFC: 1.5, engine oil (a softener): 60, Sulfur: 3, Accelerator M: 1.5 and Accelerator TMTD: 0.2.

[0022] Normal temperature special soft glue is made as follows:

[0023] 1. Rubber mixing equipment: Since the amount of this type of rubber is small, an open rubber mixing machine can be used for plasticizing and mixing of raw rubber. The temperature of the raw rubber plasticizing roller is 50°C-55°C, and the temperature of the mixing roller is 55°C-60°C.

[0024] 2. Raw rubber mastication: the natural standard rubber must be masticated for more than four sections, and the number of times for each section is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com