Controlled release fertilizer with high content of biological carbon and preparation method thereof

A technology of controlled-release fertilizer and bio-carbon, which is applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of large waste of raw materials, single controlled-release mechanism, and inability to be directly applied, and achieves low production cost, flexible formulation application, and economical savings. Effects of raw materials and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

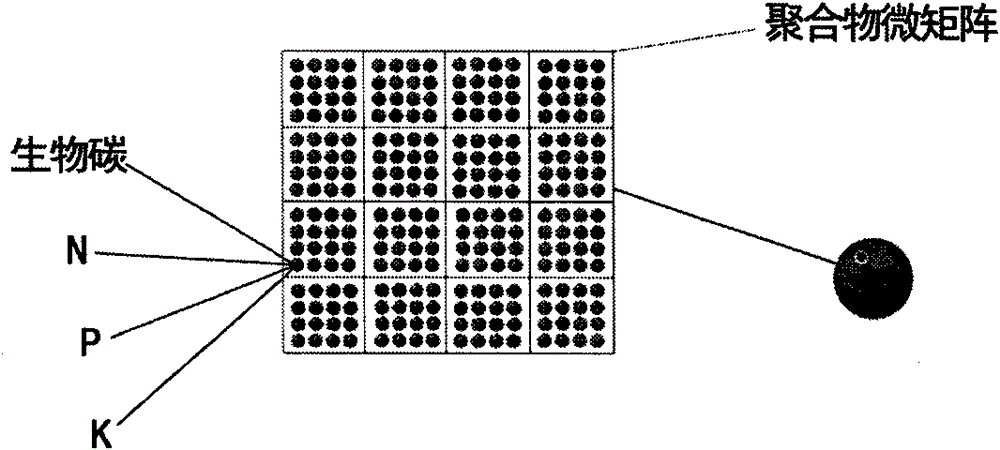

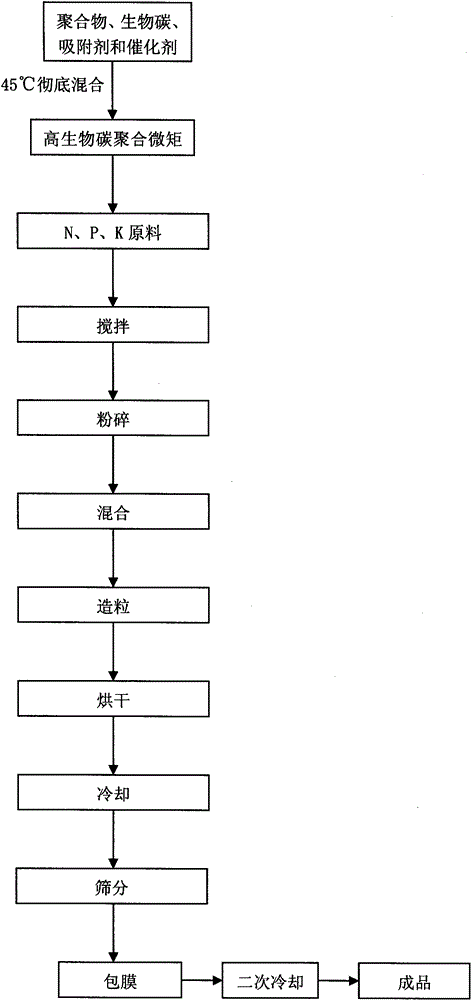

[0031] The preparation process of high biological carbon controlled release fertilizer is as follows: figure 2 As shown, it mainly includes two parts:

[0032] 1. Preparation of high biochar controlled release agent:

Embodiment 1

[0034] Mix polyvinyl alcohol, polyvinyl acetic acid, and carbonized formaldehyde cellulose at a weight ratio of 40:40:20 as polymer ingredients, and combine biochar produced by smokeless coking technologies such as orange stalks with calcium bentonite as an adsorbent at a ratio of 90: 10 weight ratio mixing; 0.1% weight ratio of polymer ingredients and 99% weight ratio of biochar and adsorbent mixture, and 0.9% weight ratio of catalyst propylene glycol are thoroughly mixed to make a high biochar slow-release agent, mixed granules The diameter is controlled at 80-100 mesh (grid), and the mixing temperature is 45-65°C.

Embodiment 2

[0036] The cellulose polymer ethlcellalose is used as a polymer ingredient, and the biochar produced by smokeless coking technologies such as orange stalks is mixed with zeolite powder as an adsorbent in a weight ratio of 90:10; the polymer ingredient of 45% by weight and 54.98 % weight ratio of biochar and adsorbent mixture, and 0.02% weight ratio of catalyst ethylene glycol are thoroughly mixed to make a high biochar slow-release agent. The particle size after mixing is controlled at 80-100 mesh (grid), and the mixed The temperature is 45-65°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com