Double-shell hollow spherical organic metal framework material and preparation method thereof

An organometallic, hollow spherical technology, applied in the direction of organic chemistry, zinc organic compounds, etc., can solve problems such as unseen technical solutions, achieve high chemical and thermal stability, large specific surface area, and wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

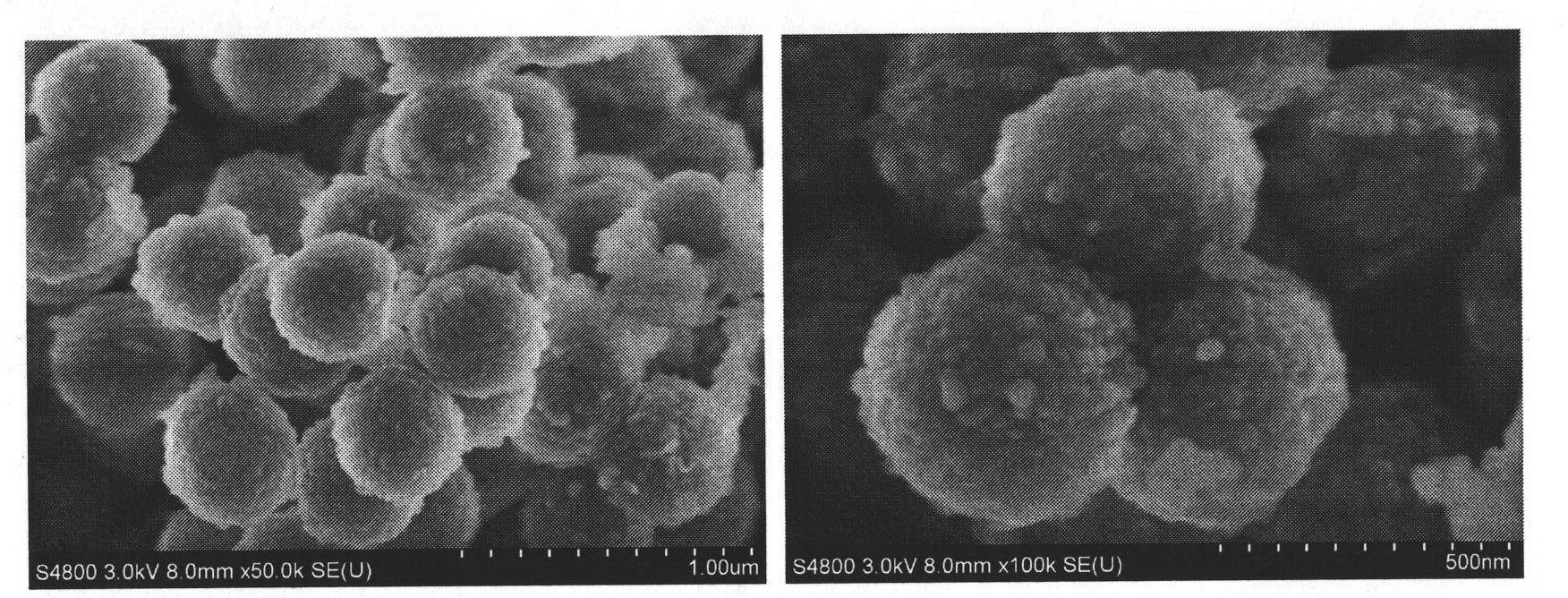

[0039] Preparation of sulfonated PS beads template: At room temperature, 10 g of freeze-dried hollow PS beads were ultrasonically dispersed in 300 ml of concentrated H 2 SO 4 , stirred in an oil bath at 40°C for 15 minutes, dispersed in a mixed solution of 1000 ml of water and ethanol, settled, centrifuged, washed until neutral, and freeze-dried to prepare sulfonated PS pellets for later use.

Embodiment 2

[0041] Take 200 mg of the above-mentioned sulfonated PS pellets, disperse them in 45 ml of methanol with 90 W ultrasound, and stir for 10 minutes. Methanol solution of zinc nitrate hexahydrate Dissolve 0.667g of zinc nitrate hexahydrate in 45ml of methanol, add and continue to stir, add 1.47g of 2-methylimidazole after 10 minutes, stir for an hour, let stand, centrifuge, wash with methanol, Drying at 40°C overnight gave a white solid.

Embodiment 3

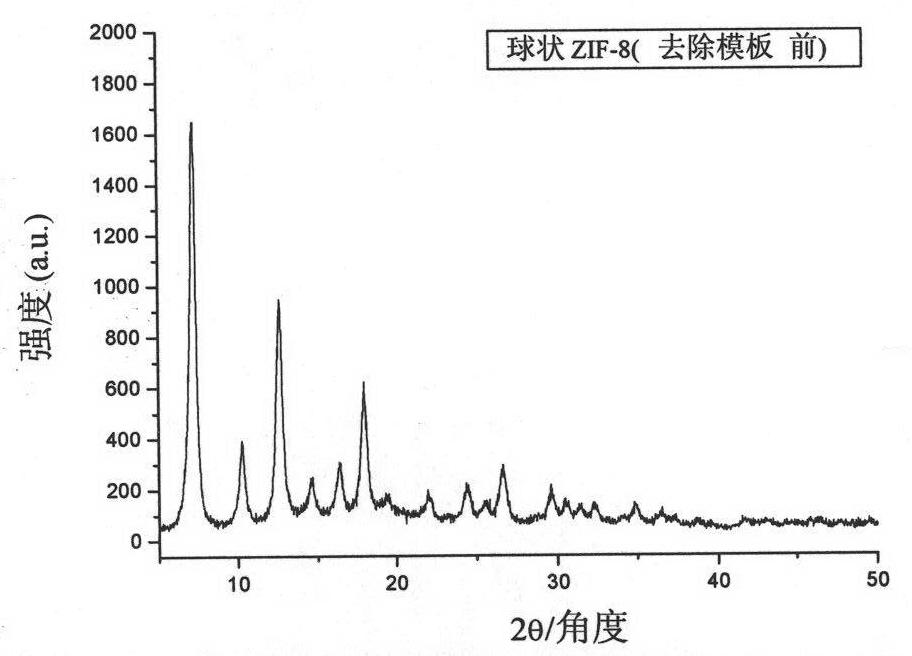

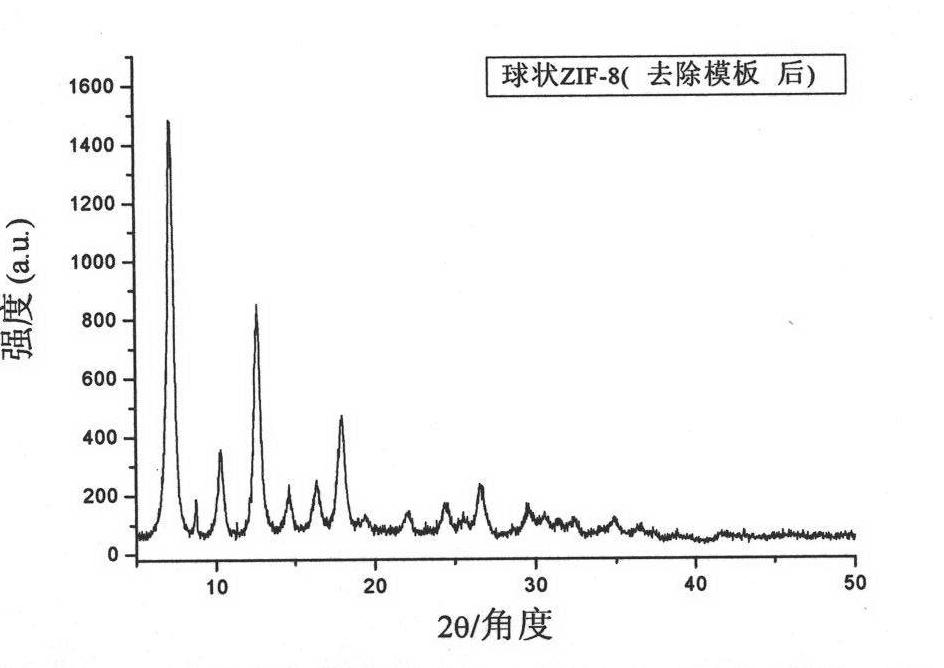

[0043] The above-mentioned obtained white solid was post-treated, and in N 2 Under protection, calcined at 350° C. for 3 hours to remove the template to obtain a spherical organometallic framework compound ZIF-8 with double shells.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com