Method for regulating metallic silicides source/drain Schottky barrier height

A technology of metal silicide source and Schottky potential, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of reduced driving current and increased leakage current, and achieves reduced difficulty and cost and continuous regulation Ability, easy to adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

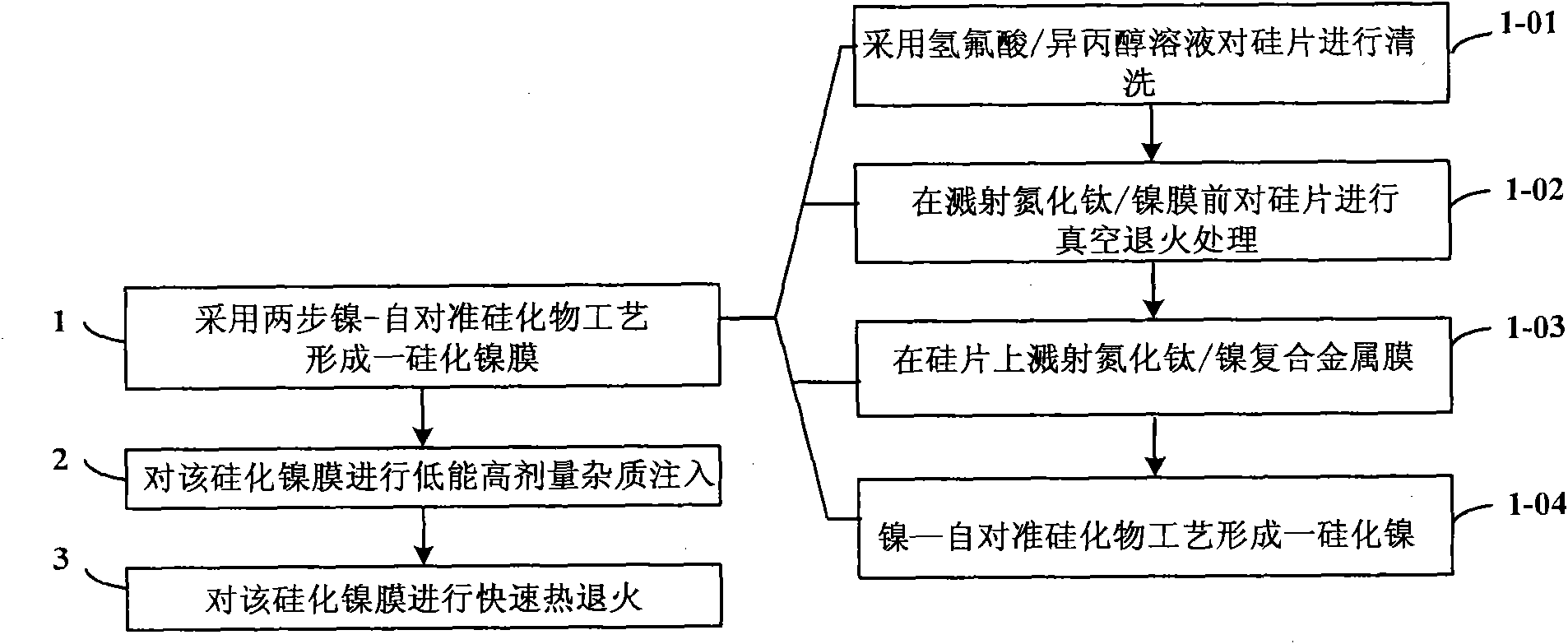

[0029] Such as figure 1 as shown, figure 1 It is a flow chart of a method for adjusting the height of metal silicide source / drain Schottky barriers provided by the present invention, and the method includes:

[0030] Step 1: Form a nickel silicide film using a two-step nickel-salicide process; specifically include:

[0031] First, the silicon chip is cleaned with hydrofluoric acid / isopropanol solution; that is, after routine cleaning, it is cleaned in hydrofluoric acid / isopropanol solution, and the proportion (volume ratio) of hydrofluoric acid / isopropanol solution is : hydrofluoric acid: isopropanol: deionized water=37.5ml: 6ml: 3000ml, soaked for 40 seconds at room temperature;

[0032] Then, vacuum anneal the silico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com