Solid sol type aerosol fire extinguishing agent and preparation method thereof

An aerosol and fire extinguishing agent technology, applied in the direction of fire prevention equipment, etc., can solve the problems that the uniformity of mixing cannot be achieved, the degree of mixing uniformity depends on the degree of crushing, and the impact on the environment is large, so as to achieve safety and environmental protection. The effect of low investment, reducing production energy consumption and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Formula (parts by weight):

[0039] Oxidizing agent 55; Reducing, combustible agent 43;

[0040] Additive 1; Water 30.

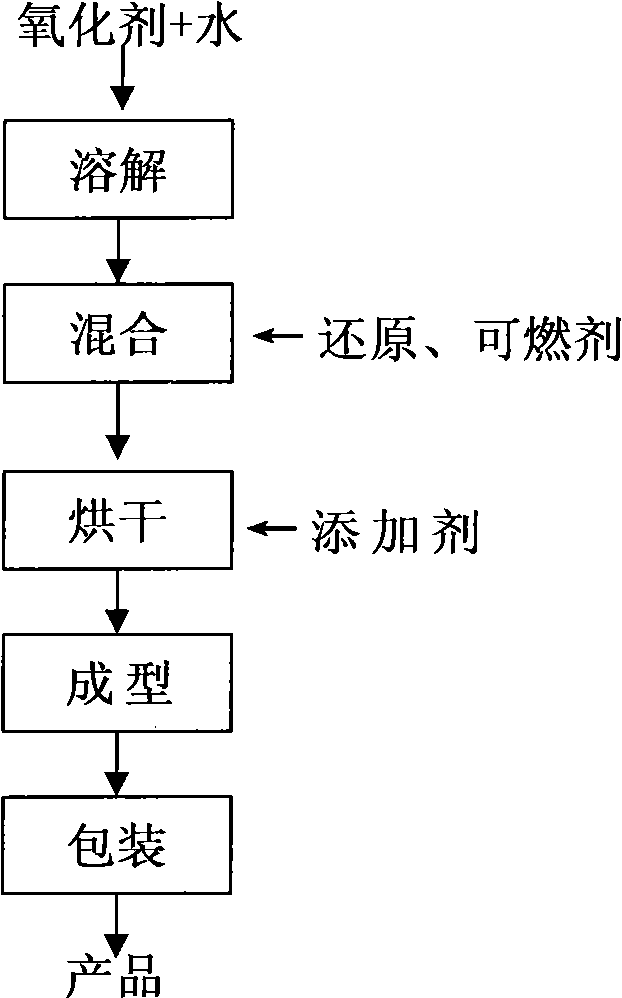

[0041] 2. Process steps:

[0042] 1. Dissolution: first add 30 parts of water into the reaction pot, add 55 parts of oxidant, fully stir and dissolve under heating conditions to form an aqueous solution of oxidant;

[0043] 2. Mixing: Add 43 parts of reducing and combustible agents to the above oxidant aqueous solution, dissolve and mix evenly under the condition of heating and stirring;

[0044] 3. Drying: dry the mixture until its water content is less than 1%;

[0045] 4. Molding: casting the dried mixture into a mould, and then sealing and packing to obtain the product of the present invention.

Embodiment 2

[0047] 1. Formula (parts by weight):

[0048] Oxidizing agent 50; Reducing, combustible agent 50;

[0049] Additive 2; Water 35.

[0050] 2. Process steps:

[0051] 1. Dissolution: First add 25 parts of water into the reaction pot, add 50 parts of oxidant, and fully stir and dissolve under heating conditions to form an aqueous solution of oxidant;

[0052] 2. Mixing: Add 50 parts of reducing and combustible agents to the above oxidant aqueous solution, dissolve and mix evenly under the condition of heating and stirring;

[0053] 3. Drying: dry the mixture until its water content is less than 1%;

[0054] 4. Molding: cast the dry mixture into a mold, and seal and pack to obtain the product of the present invention

Embodiment 3

[0056] 1. Formula (parts by weight):

[0057] Oxidizing agent 45; reducing, combustible agent 55;

[0058] Additive 2; Water 30.

[0059] 2. Process steps:

[0060] 1. Dissolution: First add 30 parts of water into the reaction pot, add 45 parts of oxidant, fully stir and dissolve under heating conditions to form an aqueous solution of oxidant;

[0061] 2. Mixing: Add 55 parts of reducing and combustible agents to the above oxidant aqueous solution, dissolve and mix evenly under the condition of heating and stirring;

[0062] 3. Drying: dry the mixture until its water content is less than 1% and add 3 parts of additives;

[0063] 4. Molding: cast the dry mixture into a mold, and seal and pack to obtain the product of the present invention

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com