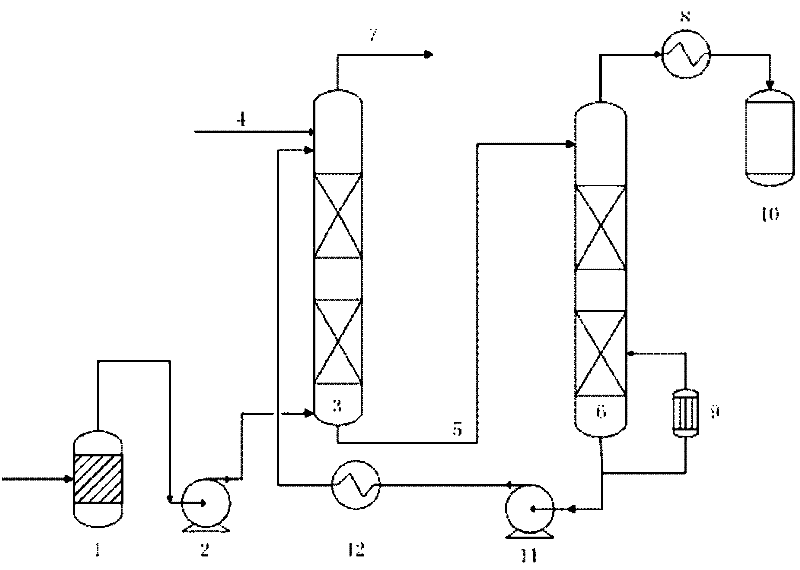

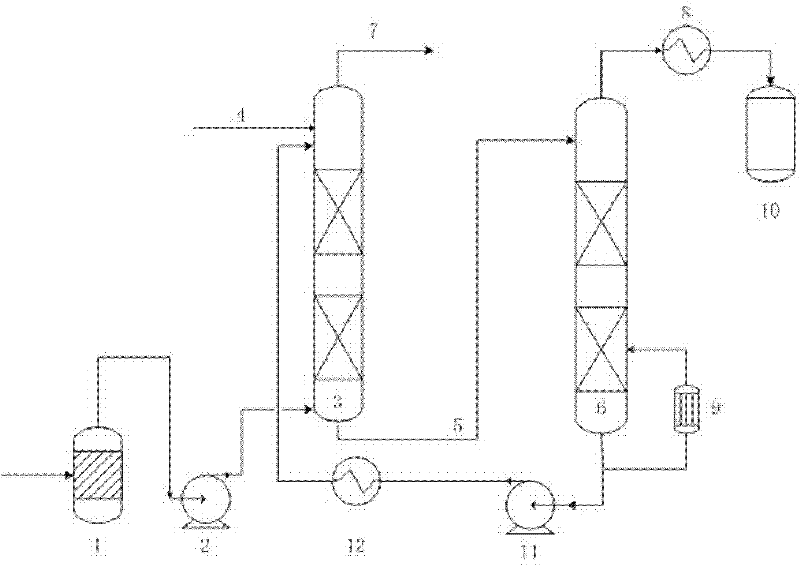

Resource tail gas treatment system and technology for soil vapor extraction repair technique

A gas-phase extraction and treatment process technology, applied in the field of soil remediation, can solve problems such as environmental risks, high heat treatment costs, and increased greenhouse gas emissions, and achieve the effects of simple absorption methods, simple device structures, and increased economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The tail gas extracted by the gas phase extraction device contains pollutants benzene, toluene and xylene, and the concentration of pollutants is 100mg / m 3 , the extraction flow rate is 200m 3 / h for example. Obtain result as follows according to above-mentioned process embodiment:

[0025] Original pollutant content

Embodiment 2

[0027] The tail gas extracted by the gas phase extraction device contains pollutants benzene, toluene and xylene, and the concentration of pollutants is 300mg / m 3 , the extraction flow rate is 600m 3 / h for example. Obtain result as follows according to above-mentioned process embodiment:

[0028] Original pollutant content

[0029] It can be seen from the above process that the present invention has made an invention and innovation for the treatment of high-concentration pollutant tail gas in the process of gas-phase extraction and restoration of soil. It uses high-efficiency absorbent to absorb, and the absorption rate can reach 99.99%, and the content of organic pollutants in the air fully meets the national regulations. The pollution discharge standard solves the problem of air pollution. In addition, the volatile organic pollutants can be effectively recovered, and the recovery rate can reach more than 99.9%, and the solvent can be recycled, and the regenera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com