Method for preparing functional polyester masterbatch from regenerative polyester bottle chips and device for method

A technology of polyester masterbatch and recycled polyester, which is applied in the field of textile raw material processing, and can solve problems such as antistatic, anti-ultraviolet, antibacterial, purity of polyester masterbatch, and technical inspiration of polyester masterbatch. , to achieve the effect of improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

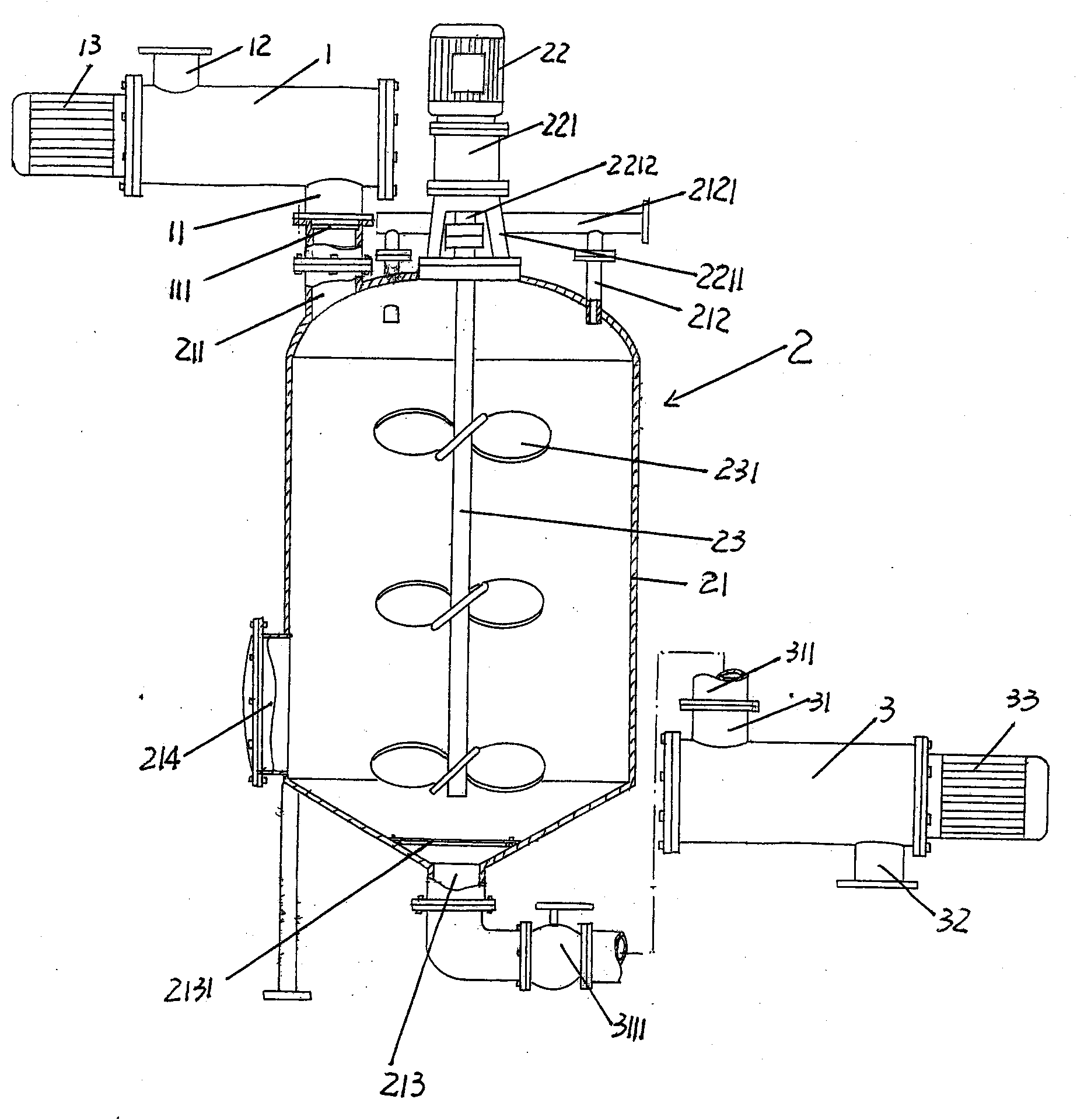

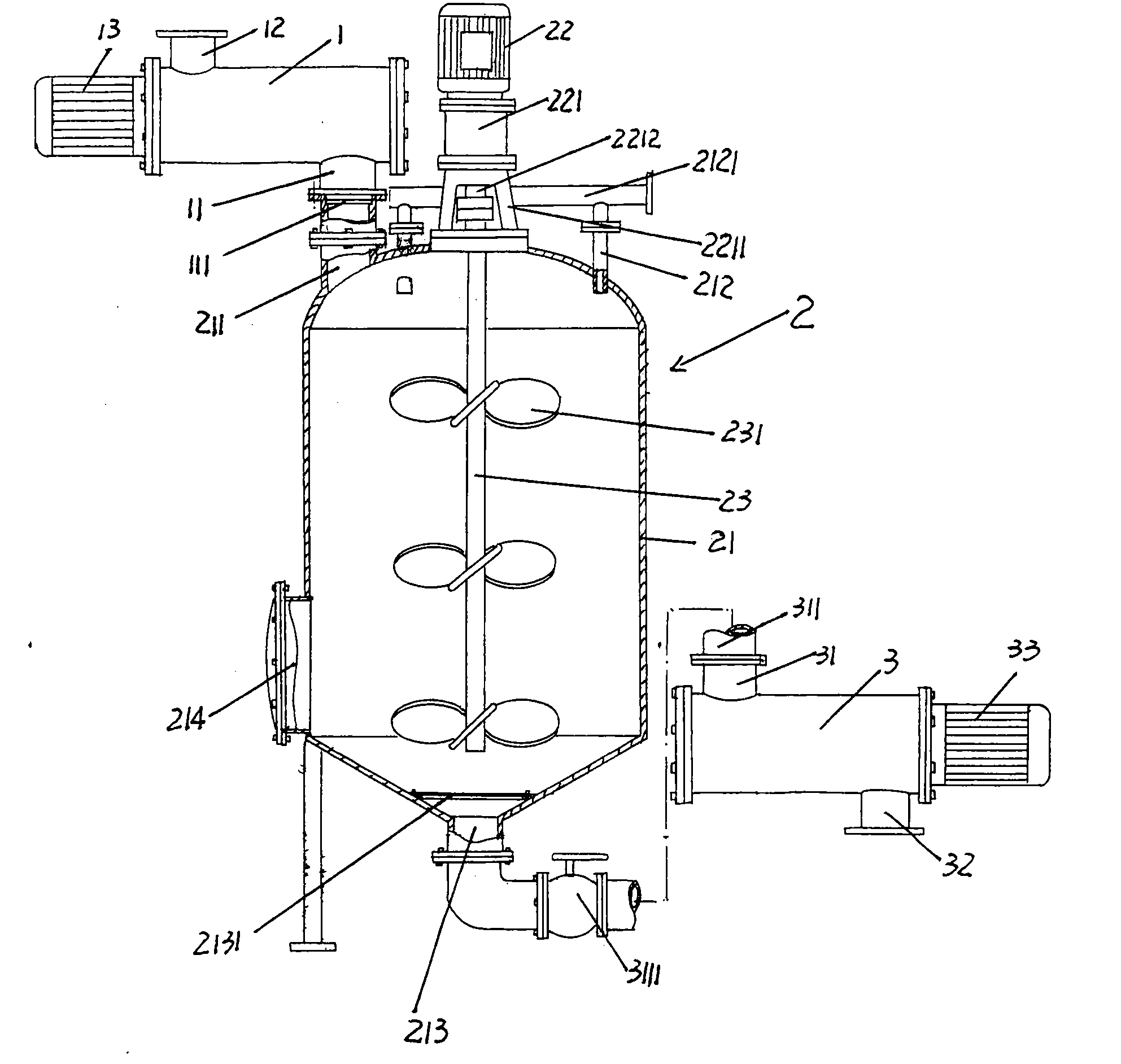

[0023]Specifically in conjunction with Fig. 1, will be introduced from the screw extruder feeding port 12 of the first screw extruder 1 by commercially available regenerated polyester bottle flakes, under the work of the working motor 13 of the first screw extruder 1, make The first screw extruder 1 works to melt the regenerated polyester bottle flakes into a regenerated polyester bottle flake melt (also known as a melt), and extrude from the extruder outlet 11, and pass through the aforementioned mesh After being filtered by the 700-mesh melt screen 111 , it enters the barrel 21 of the mixer 2 . In this embodiment, the temperature of the first screw extruder 1, that is, the extrusion temperature is controlled at 300°C, the extrusion pressure is controlled at 15MPa, the screw speed is controlled at 70n / min, and the polyester melt entering the barrel 21 Under the operation of the stirring motor 22 of the mixer 2, the speed reducer 221 decelerates to drive the stirring shaft 23 ...

Embodiment 2

[0025] Only change the extrusion temperature, pressure and screw speed of the first screw extruder 1 to 330°C, 12MPa and 50n / min respectively, and change the mesh number of the melt filter 111 to 500 mesh; The amount of nano-scale ceramic powder is changed to 0.5%, nano-scale iron oxide (antistatic agent) 1%, nano-scale titanium oxide (anti-ultraviolet) 0.5%, copper oxide 0.3%, lithium carbonate 0.2% and as a flame retardant Aluminum hydroxide 1% and magnesium hydroxide 1%, the pressure in cylinder body 21, temperature and the rotating speed of stirring shaft 23 are respectively changed into 10MPa, 285 ℃ and 6n / min, and the mesh number of stirring liquid filter screen 2131 is changed into 300 mesh; adjust the extrusion temperature, pressure and screw speed of the second screw extruder 3 to 270°C, 12MPa and 50n / min respectively to obtain a function with far-infrared function, anti-ultraviolet function, antibacterial function and flame-retardant function Polyester masterbatch, a...

Embodiment 3

[0027] Only change the extrusion temperature, pressure and screw speed of the first screw extruder 1 to 315°C, 13.5MPa and 60n / min respectively, and the mesh number of the melt filter 111 to 600 mesh; The material is changed to 1% nano-scale antimony oxide, the pressure and temperature in the cylinder 21 and the rotating speed of the stirring shaft 23 are respectively changed to 11MPa, 280°C and 8n / min, and the mesh number of the stirring liquid filter 2131 is changed to 250 mesh Change the extruding temperature and pressure of the second screw extruder 3 and the screw speed to 285°C, 11.5MPa and 70n / min respectively to obtain a functional polyester masterbatch with a flame-retardant function, and all the other are the same as those of Example 1 describe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com