Activated carbon washing-resisting electrode and preparation method and application thereof

An activated carbon and erosion-resistant technology, which is applied in the direction of active material electrodes, electrode manufacturing, circuits, etc., can solve the problems that cannot be applied to the treatment occasions with a large amount of sewage, the powder of the mixture is easy to fall off, and cannot handle sewage, etc., and achieves high hardness and bonding Good sex, good overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Activated carbon erosion-resistant electrode, and preparation method thereof

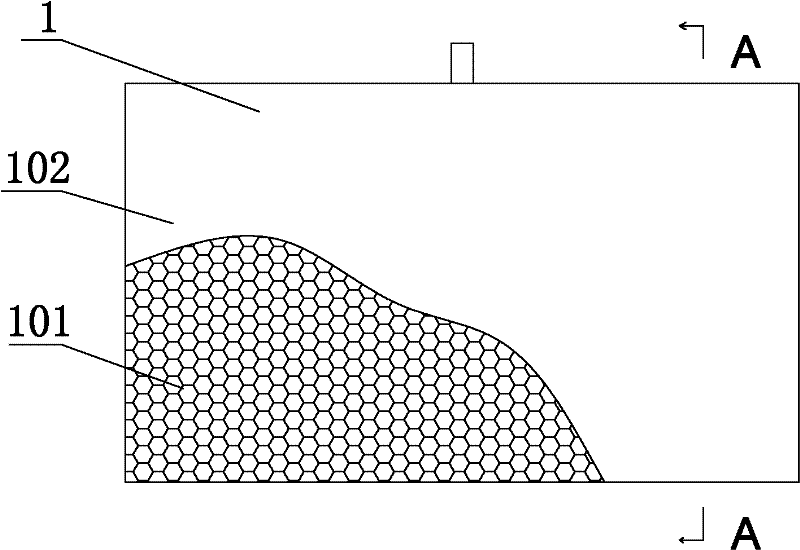

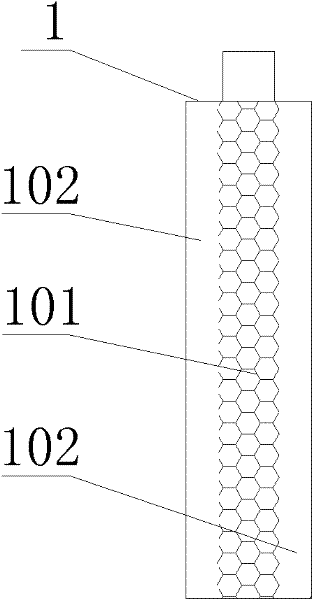

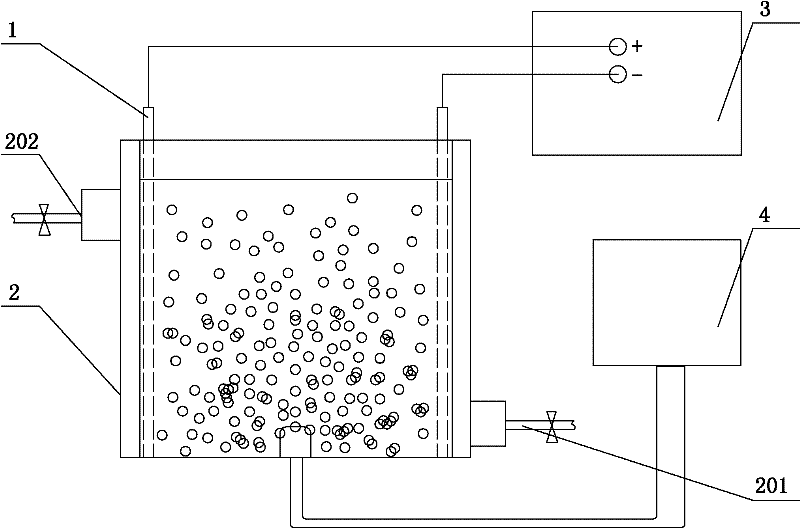

[0039] a kind of like figure 1 , figure 2 The shown activated carbon erosion-resistant electrode 1 includes a foamed nickel substrate 101, and the surface and pores of the foamed nickel substrate 101 are filled with activated carbon mixed material 102. The activated carbon mixed material 102 includes activated carbon, acetylene black, polytetrafluoroethylene and carboxymethyl The mass ratio of activated carbon, acetylene black, polytetrafluoroethylene, and carboxymethyl cellulose in the cellulose-activated carbon mixed material 102 is 3:1.5:2:0.01875. The activated carbon erosion-resistant electrode 1 is in the shape of a sheet, and the loading capacity of the activated carbon mixed material on the sheet-shaped activated carbon erosion-resistant electrode 1 is 0.45kg / m 2 ~0.50kg / m 2 .

[0040] The activated carbon erosion-resistant electrode 1 is prepared through the following steps:

...

Embodiment 2

[0058] Activated carbon erosion-resistant electrode, and preparation method thereof

[0059] a kind of like figure 1 , figure 2 The shown activated carbon erosion-resistant electrode 1 includes a foamed nickel substrate 101, and the surface and pores of the foamed nickel substrate 101 are filled with activated carbon mixed material 102. The activated carbon mixed material 102 includes activated carbon, acetylene black, polytetrafluoroethylene and carboxymethyl The mass ratio of activated carbon, acetylene black, polytetrafluoroethylene, and carboxymethyl cellulose in the cellulose-activated carbon mixed material 102 is 4:1:2.3:0.0375. The activated carbon erosion-resistant electrode 1 is in the shape of a sheet, and the loading capacity of the activated carbon mixed material on the sheet-shaped activated carbon erosion-resistant electrode 1 is 0.45kg / m 2 ~0.50kg / m 2 .

[0060] The activated carbon erosion-resistant electrode 1 is prepared through the following steps:

[...

Embodiment 3

[0078] Activated carbon erosion resistant electrode and its preparation

[0079] a kind of like figure 1 , figure 2 The shown activated carbon erosion-resistant electrode 1 includes a foamed nickel substrate 101, and the surface and pores of the foamed nickel substrate 101 are filled with activated carbon mixed material 102. The activated carbon mixed material 102 includes activated carbon, acetylene black, polytetrafluoroethylene and carboxymethyl The mass ratio of activated carbon, acetylene black, polytetrafluoroethylene, and carboxymethyl cellulose in the cellulose-activated carbon mixed material 102 is 5:0.5:3.1:0.07. The activated carbon erosion-resistant electrode 1 is in the shape of a sheet, and the loading capacity of the activated carbon mixed material on the sheet-shaped activated carbon erosion-resistant electrode 1 is 0.45kg / m 2 ~0.50kg / m 2 .

[0080] The activated carbon erosion-resistant electrode 1 is prepared through the following steps:

[0081] (1) Ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com