Selective hydrogenation method for phenylacetylene in phenylacetylene-containing styrene material flow

A technology for selective hydrogenation and phenylacetylene, applied in chemical instruments and methods, hydrocarbons, chemical/physical processes, etc., can solve problems such as excess hydrogen and increased styrene loss, and ensure utilization and consistency sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

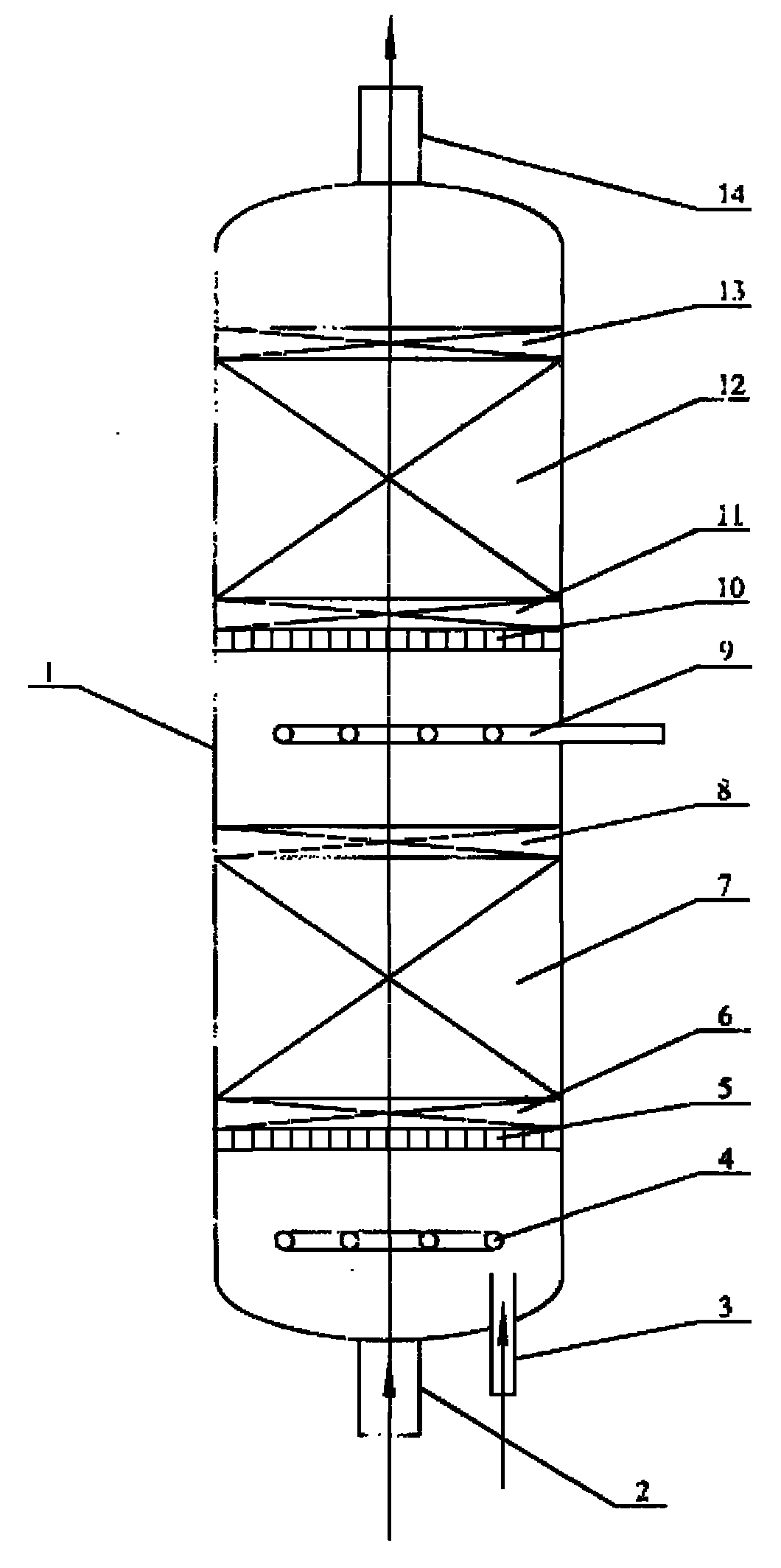

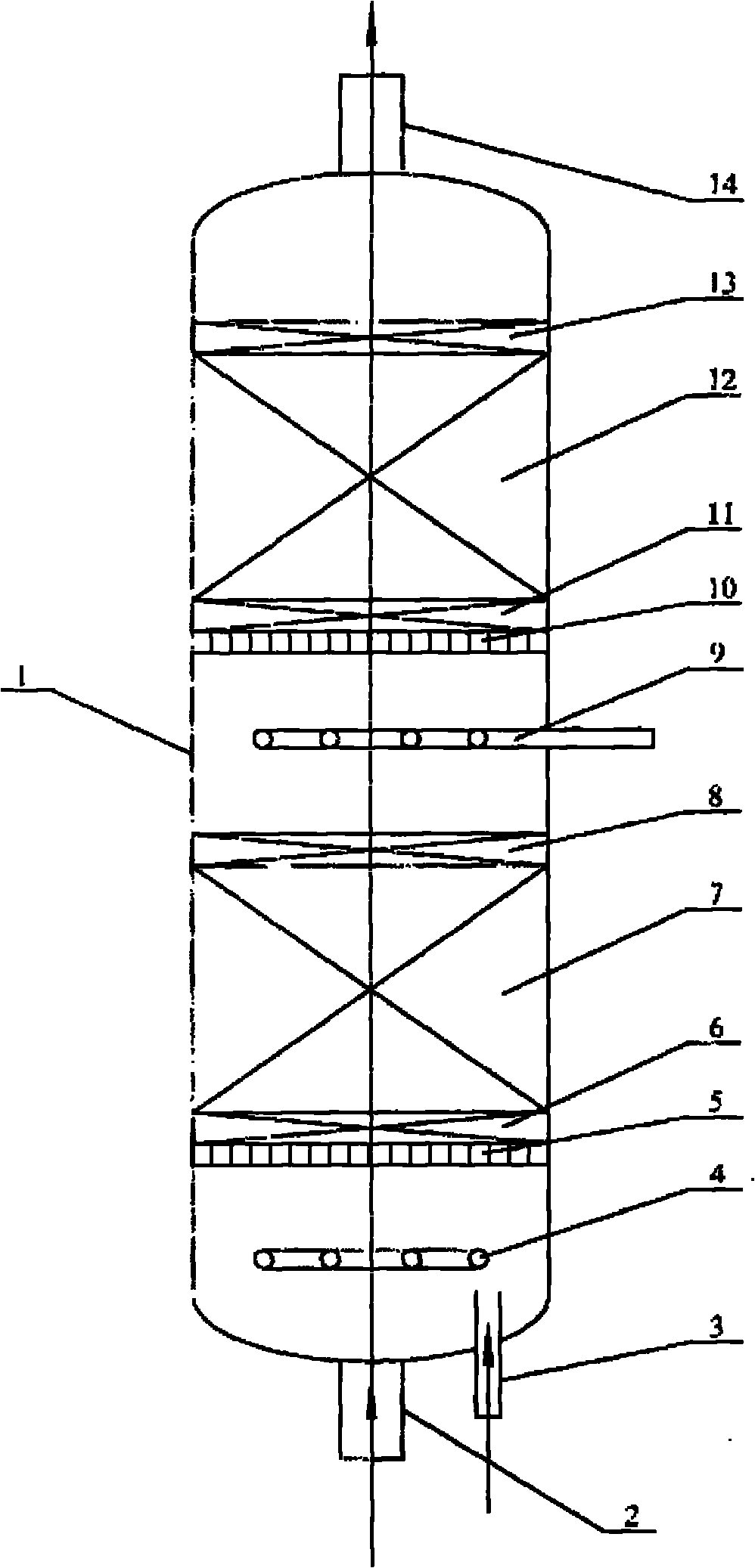

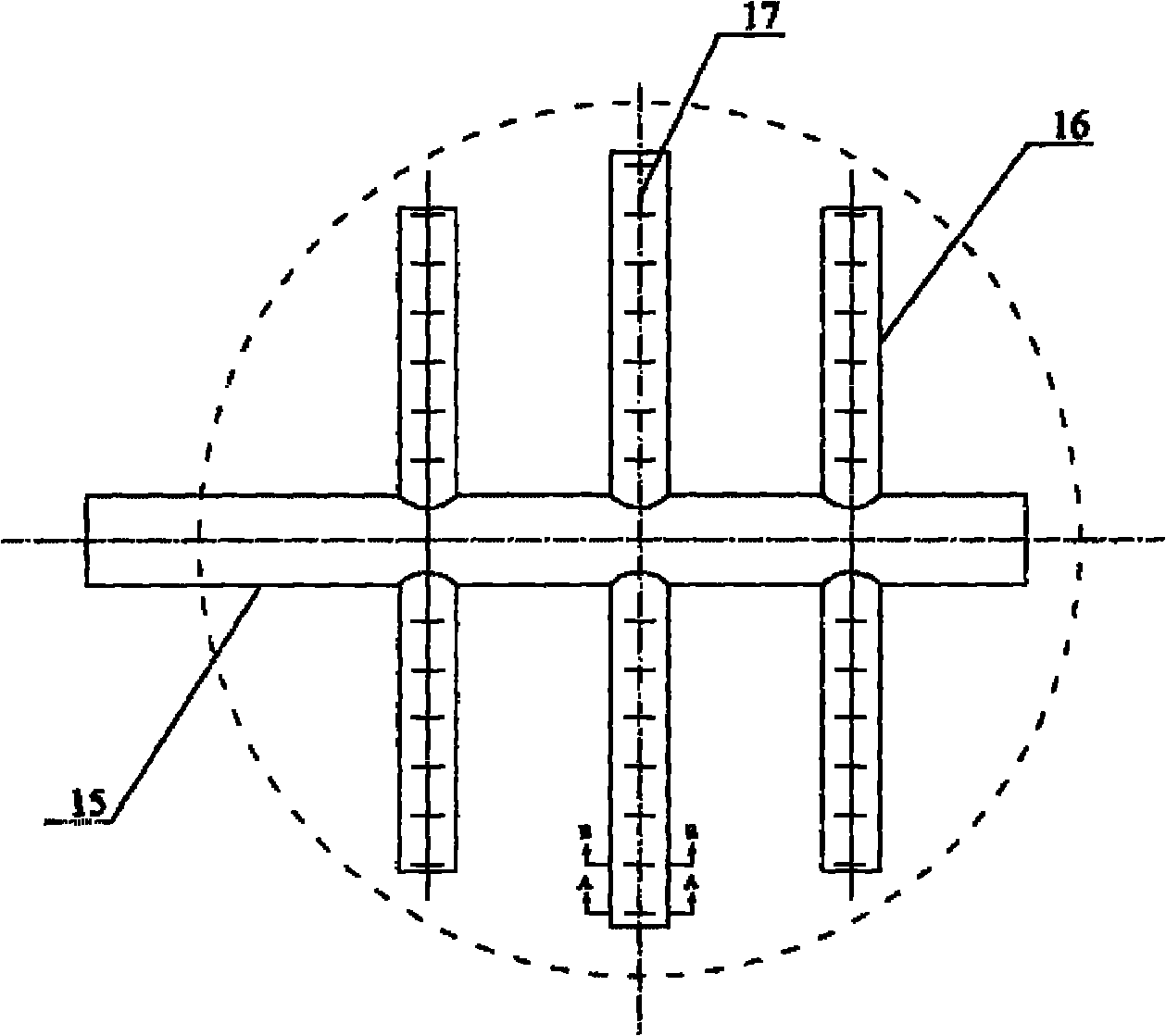

[0028] According to Figure 1, Figure 2 and Figure 7, the diameter of the gas-liquid-solid three-phase multi-stage fixed bubbling bed reactor is 1000 mm, and the catalyst bed is 2 layers. Catalyst 0.5% by weight Pd / Al 2 o 3 palladium-containing catalyst. Dendritic gas distributor distributed in parallel, each branch pipe is arranged at equal intervals in the same section of the reactor, and there are two rows of small holes on the branch pipe, and the small holes are evenly distributed along the length of the pipe. The diameter of the main pipe is 100 mm, and there are 4 branch pipes with a diameter of 50 mm. The small holes on the branch pipes are circular with a diameter of 5 mm. into an angle of 30°. Hydrogen is a mixture of hydrogen and nitrogen, and the molar ratio of nitrogen to hydrogen is 0.5. A C8 hydrocarbon fraction comprising 25% by weight of styrene, 11% by weight of ethylbenzene and 1500ppm phenylacetylene is added to the bottom of the reactor, a part of hydro...

Embodiment 2

[0030] According to Figure 1, Figure 2 and Figure 9, the diameter of the gas-liquid-solid three-phase multi-stage fixed bubbling bed reactor is 1500 mm, and the catalyst bed is 2 layers. Catalyst 1.5 wt% Ni / Al 2 o 3 nickel-containing catalysts. Dendritic gas distributor distributed in parallel, each branch pipe is arranged at equal intervals in the same section of the reactor, with two rows of open short pipes on the branch pipe, and the open short pipes are staggered and evenly distributed along the length of the pipe. The diameter of the main pipe is 100 mm, and there are 8 branch pipes with a diameter of 40 mm. The small holes on the short pipe with holes are circular with a diameter of 4 mm. The reactor axis forms an included angle of 60°. Hydrogen is pure hydrogen. A C8 hydrocarbon cut comprising 30% by weight of styrene, 10.5% by weight of ethylbenzene and 3500ppm phenylacetylene is added to the bottom of the reactor, a part of hydrogen is also added to the bottom of...

Embodiment 3

[0032] According to Figure 1, Figure 2 and Figure 5, the diameter of the gas-liquid-solid three-phase fixed bubbling bed reactor is 1000 mm, and the catalyst bed is 2 layers. Catalyst 1.5 wt% Ni / Al 2 o 3 nickel-containing catalysts. Dendritic gas distributor distributed in parallel, each branch pipe is arranged at equal intervals in the same section of the reactor, the small holes on the branch pipe are 1 row, and the holes are opened along the axial direction of the reactor, and the small holes are evenly distributed along the length of the pipe. The diameter of the main pipe is 80 mm, and there are 12 branch pipes with a diameter of 30 mm. The small holes are circular with a diameter of 5 mm. The total area of the holes is 1.5 times the cross-sectional area of the branch pipes. Hydrogen is a mixture of hydrogen and nitrogen, and the molar ratio of nitrogen to hydrogen is 0.3. A C8 hydrocarbon cut comprising 35% by weight of styrene, 8% by weight of ethylbenzene and 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com