Method for component content prediction and optimization operation in wet-process metallurgic extraction process

A technology of hydrometallurgy and component content, applied in the direction of electrical program control, comprehensive factory control, instruments, etc., can solve the problems of increased product cost, increased consumption of auxiliary materials, and difficulty in ensuring the first pass rate, etc., to ensure product quality, The effect of optimal control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

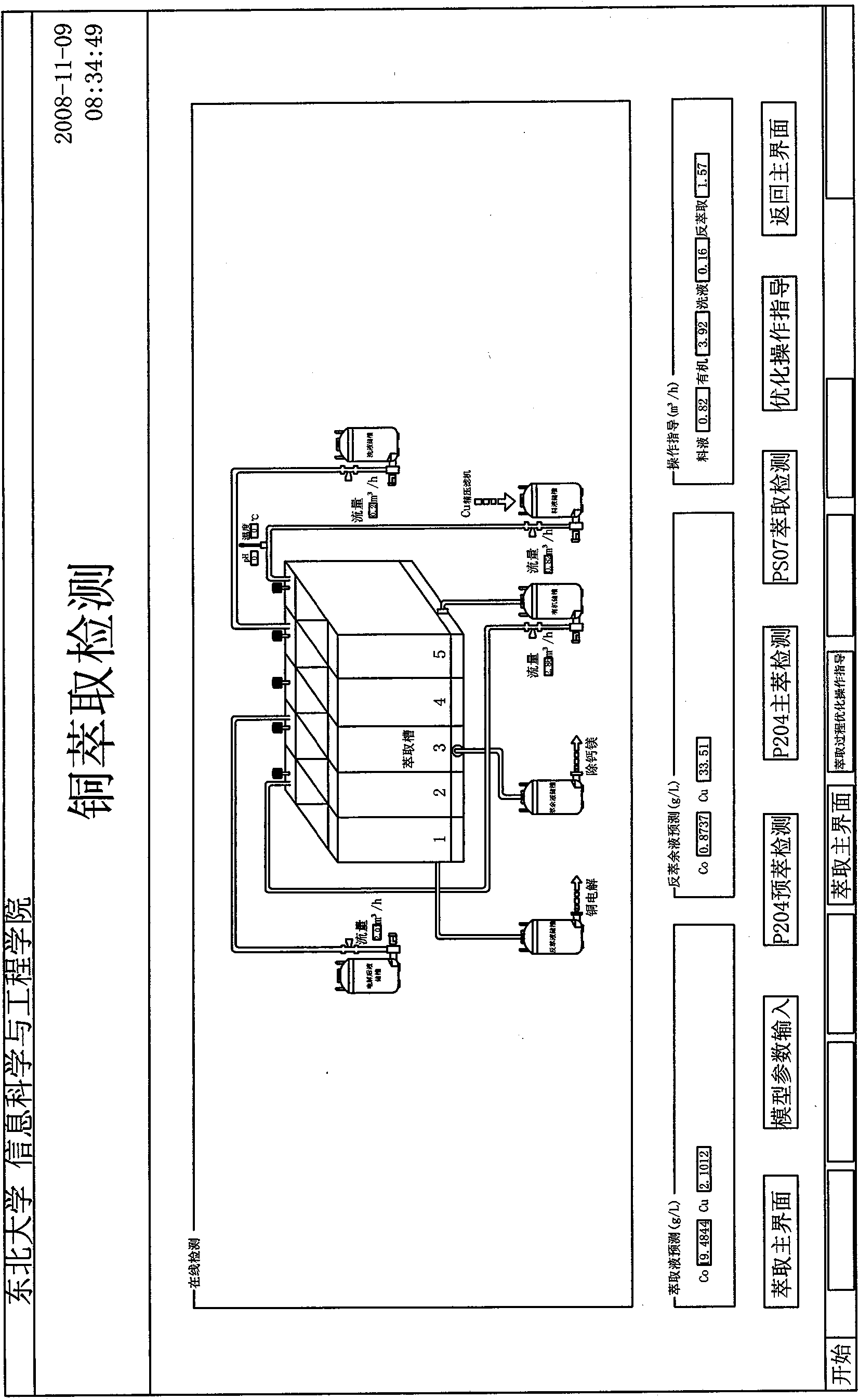

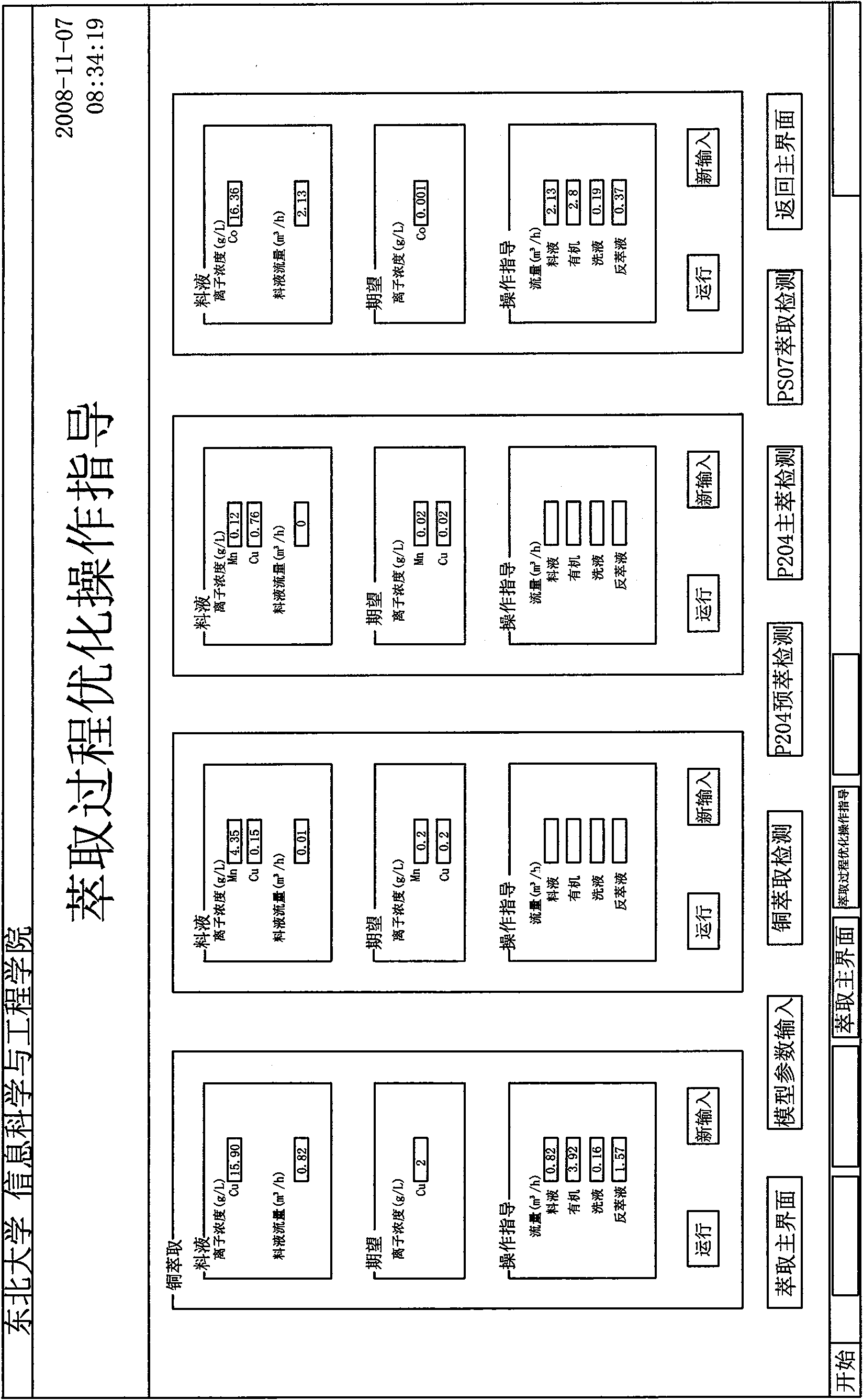

[0144] Implementation on the copper extraction and impurity removal production line.

[0145] There are 5 stages of cascaded extraction tanks for copper extraction on this production line, 2 stages for extraction, 1 stage for washing, 2 stages for stripping, a total of 5 stirring motors, 4 flow meters, 4 pumps, and 4 frequency conversion device, a pH meter, and a thermometer. The extraction process detection system is mainly composed of flow detection, pH value detection and temperature detection.

[0146] PLC controller adopts CPU 315-2DP of Siemens 300 series, with Profibus-DP port to connect distributed IO. Equip the PLC with an Ethernet communication module for the host computer to access PLC data. The PLC controller and Ethernet communication module are placed in the PLC cabinet in the central control room.

[0147] The pH value of the extraction process is detected online through the glass electrode produced by Cole-parmer Company, and the change of the pH value of th...

Embodiment 2

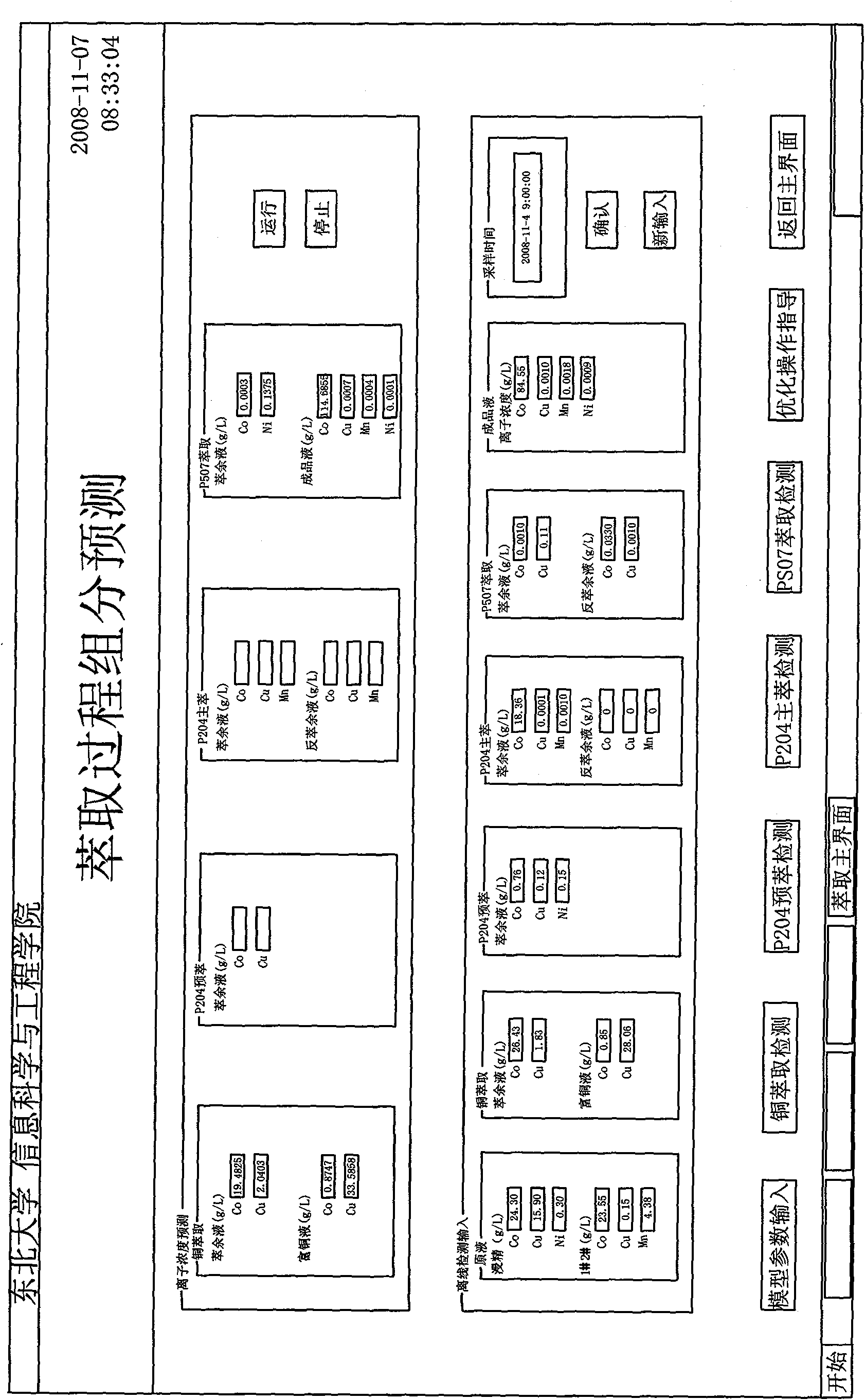

[0181] Implementation on the P204 pre-extraction and impurity removal production line.

[0182] There are 20 cascaded extraction tanks for P204 pre-extraction on this production line, 10 for extraction, 3 for washing, 3 for stripping, 3 for anti-iron, a total of 20 stirring motors, 5 flow meters , 5 pumps, 5 frequency converters, 3 pH meters, and 1 thermometer. The extraction process detection system is mainly composed of flow detection, pH value detection and temperature detection.

[0183]

serial number

Liquid

concentration

Liquid

flow

flow

The organic phase

flow

pH value

temperature

raffinate

concentration

concentration

1

4.60

3.0

0.22

2.4

4.64

15.1

0.20

0.21

2

6.35

2.0

0.25

3.0

4.45

12.4

0.22

0.21

3

4.94

2.0

0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com