Novel titanium dioxide cathode material of power lithium ion cell and preparation method thereof

A lithium-ion battery and titanium dioxide technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low charge and discharge capacity, general rate performance, and influence on the development of power lithium-ion batteries, and achieve high charge and discharge capacity and good rate The effect of performance and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

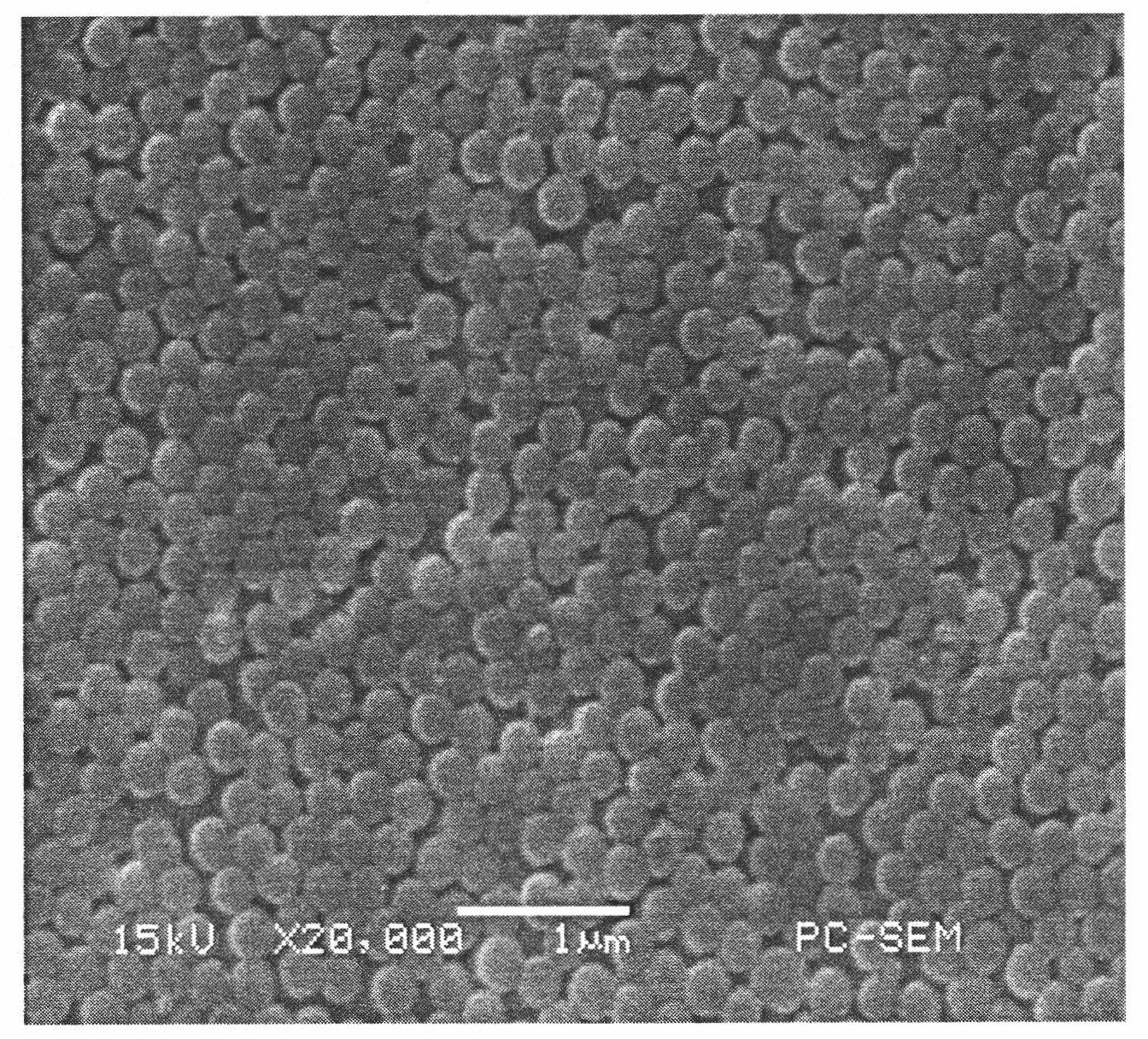

[0027] (1) 0.58g P123 (EO 20 PO 70 EO 20 ), 7g of absolute ethanol, 0.45g of oxalic acid, 7.30g of hydrochloric acid, and water were mixed with magnetic stirring for 30 minutes, and then 4.5g of tetra-n-butyl titanate was added dropwise to the mixed solution, and magnetically stirred for 1 hour.

[0028] (2) Add 4 g of polystyrene pellets synthesized by emulsifier-free polymerization into the above solution and stir magnetically for 2.5 hours, then centrifuge once to remove excess solution, and bake for 4 hours under vacuum at 60°C to obtain a new type of layered mesoporous Titanium dioxide precursor.

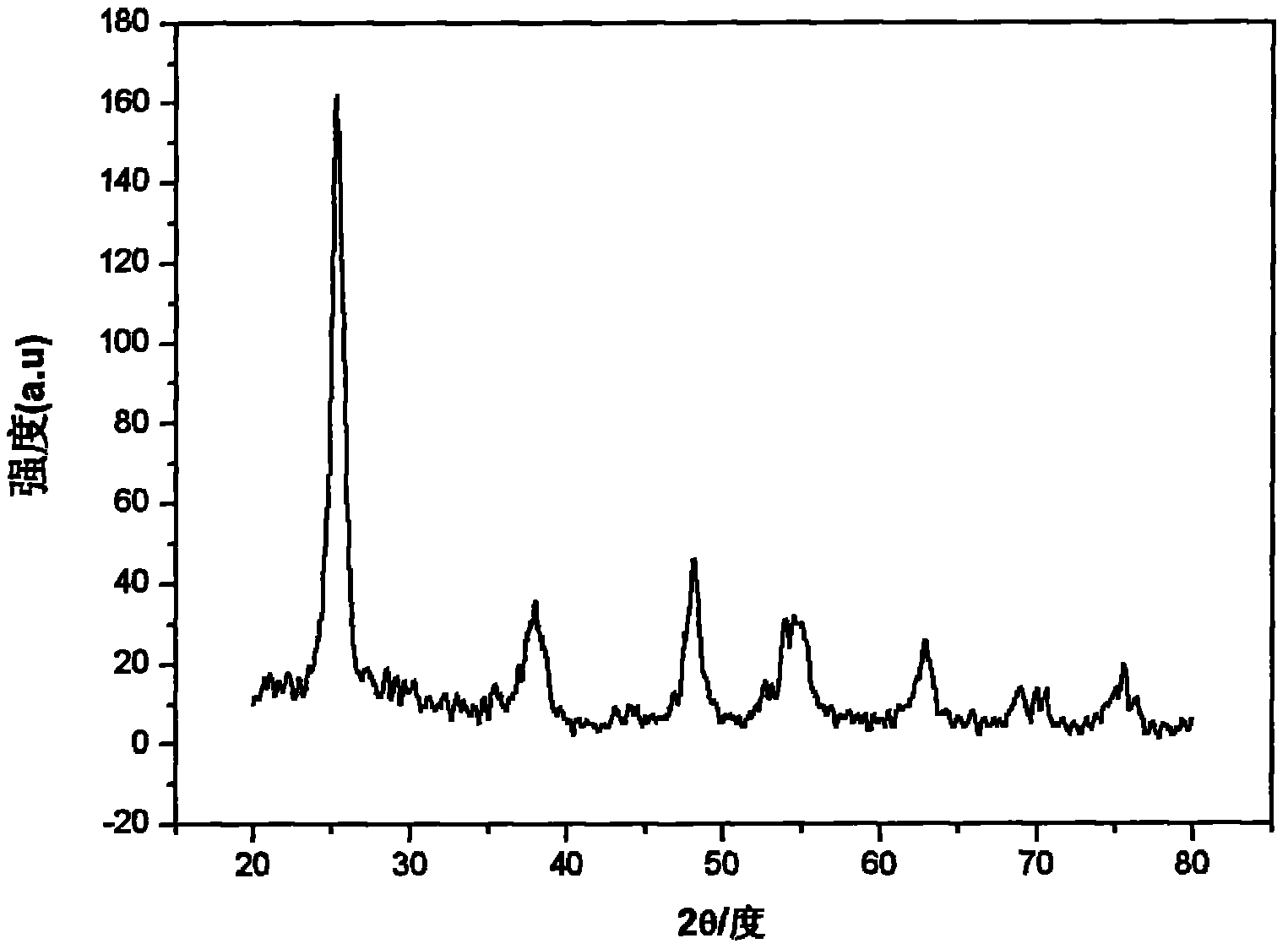

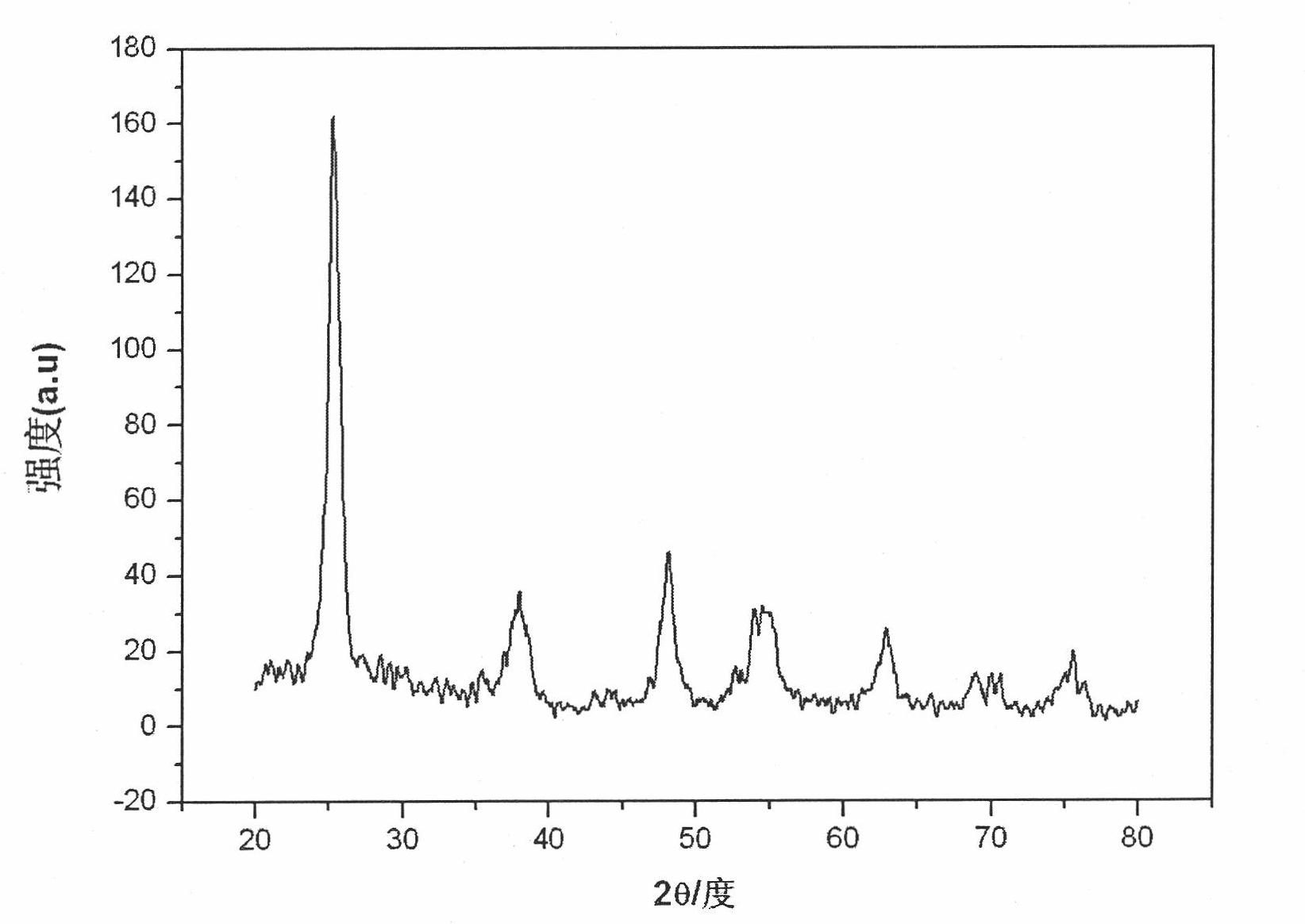

[0029] (3) The layered mesoporous titania precursor was calcined at 250°C for 2 hours, 350°C for 2 hours, and 500°C for 2 hours in an air atmosphere in a muffle furnace, with a heating rate of 2°C / min to obtain a layered Mesoporous titanium dioxide anode material.

Embodiment 2

[0031] (1) 0.2901g P123 (EO 20 PO 70 EO 20 ), 6g of absolute ethanol, 0.3g of oxalic acid, 7.30g of hydrochloric acid, and water were mixed with magnetic stirring for 30 minutes, and then 4.5g of tetra-n-butyl titanate was added dropwise to the mixed solution, and magnetically stirred for 2 hours.

[0032] (2) Add 4 g of polystyrene pellets synthesized by emulsifier-free polymerization into the above solution and stir magnetically for 2.5 hours, then centrifuge once to remove excess solution, and bake for 4 hours under vacuum at 70°C to obtain a new type of layered mesoporous Titanium dioxide precursor.

[0033] (3) The layered mesoporous titania precursor was calcined at 250°C for 2 hours, 300°C for 2 hours, and 500°C for 2 hours in an air atmosphere in a muffle furnace, and the heating rate was 2°C / min to obtain a layered Mesoporous titanium dioxide.

Embodiment 3

[0035] (1) 0.5801g P123 (EO 20 PO 70 EO 20 ), 7g of absolute ethanol, 0.6g of oxalic acid, 8g of hydrochloric acid, and water were mixed with magnetic stirring for 30 minutes, and then 3g of tetra-n-butyl titanate was added dropwise to the mixed solution, and magnetically stirred for 1 hour.

[0036] (2) Add 2 g of polystyrene pellets synthesized by emulsifier-free polymerization into the above solution and stir magnetically for 3 hours, then centrifuge twice to remove excess solution, and bake under vacuum at 60°C for 4 hours to obtain a new type of layered medium Porous titania precursor.

[0037] (3) The layered mesoporous titania precursor was calcined at 250°C for 3 hours, 350°C for 3 hours, and 550°C for 3 hours in an air atmosphere in a muffle furnace, with a heating rate of 3°C / min to obtain a layered Mesoporous titanium dioxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com