Probiotic microcapsules and preparation method thereof

A technology of probiotics and microcapsules, applied in the field of probiotics microcapsules and their preparation, can solve problems such as high price, and achieve the effects of reduced storage cost, high industrial application value and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

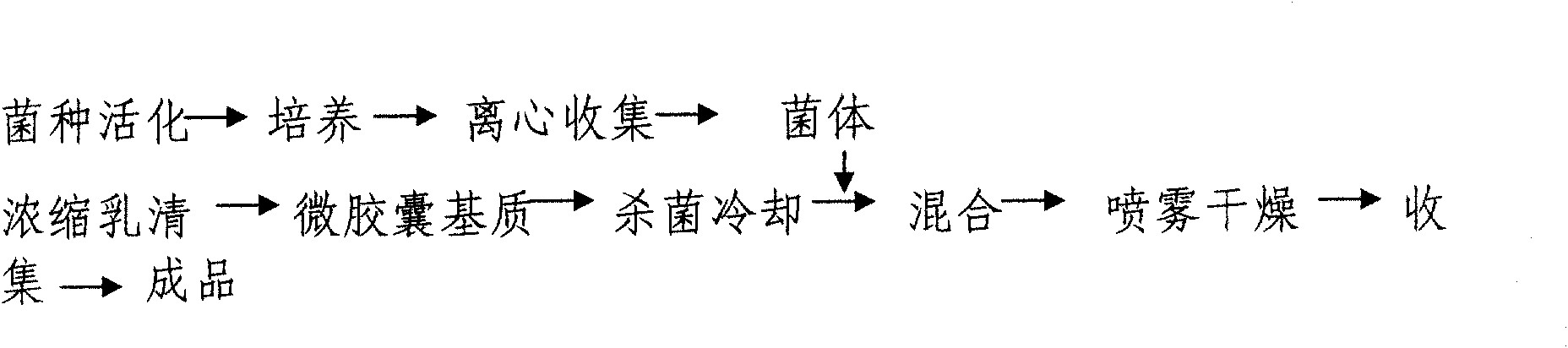

[0026] step:

[0027] 1. Strains: Culture Lactobacillus acidophilus SY-02 in MRS medium at 37°C for 12 hours, collect the bacteria by centrifugation, and set aside;

[0028] 2. Microcapsule base material: fresh whey is treated with membrane and desalted to obtain concentrated whey with a concentration of 16%-20% (protein content is 2-6%) as the base material, adding 2-6% WPI, 80-20% Heat at 90°C for 30 minutes, cool to about 45°C, and set aside;

[0029] 3. Mixing: mix the centrifuged bacteria with the microcapsule base material to make 10 10 ~10 11 cfu / ml bacterial suspension for use;

[0030] 4. Spray drying: the mixed bacteria and microcapsule base liquid are processed by spray drying equipment, the inlet air temperature is 180°C; the outlet air temperature is 80°C, and the lactic acid bacteria microcapsules are collected. The number of live bacteria in the obtained microcapsules can reach 10 10 cfu / g.

[0031] The obtained lactic acid bacteria microcapsules can be ...

Embodiment 2

[0033] Except for the following differences, it is the same as Example 1.

[0034] Among them, the probiotic strain adopts Lactobacillus bulgaricus and is cultivated according to conventional methods;

[0035] Wherein the concentrated whey protein in the microcapsule base material is used in the cheese production process, the solid content is 16%-20% (the protein content is 2-6%), and 2-6% WPI is added.

Embodiment 3

[0037] Except for the following differences, it is the same as Example 1.

[0038] Among them, the probiotic strain adopts Lactobacillus reuteri and is cultivated according to conventional methods;

[0039] Wherein the microcapsule base material is prepared by dissolving 10% by weight whey protein isolate (WPI) in water, and then adding 50mmol / L calcium chloride; the dosage of WPI can be between 8-15%.

[0040] As can be seen from the above examples, the embodiment of the present invention uses concentrated whey as the microcapsule coating material, Lactobacillus acidophilus as the capsule core, and utilizes the performance of whey protein to form a gel to combine whey and acidophilus Lactobacilli are mixed and spray-dried to form microcapsules to achieve long-term preservation of probiotics. The probiotic microcapsules prepared by the present invention can be directly added to functional milk powder products such as infant milk powder and middle-aged and elderly milk powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com