Temperature-sensitive protein molecular engram monolithic column and preparation method and application thereof

A technology of molecular imprinting and monolithic column, which is applied to the preparation method of peptides, chemical instruments and methods, and other chemical processes, can solve the problems of temperature-sensitive protein molecular imprinting monolithic columns, such as no relevant papers or patent reports, etc., to achieve Large-scale production, simple operation process, and the effect of improving the selectivity of removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A western blot material, which can be prepared as follows:

[0032] (a) Add 1.2ml of silylating reagent to methanol and mix well. The volume ratio of silylating reagent to methanol is 3:1. Two silylating reagents, methyltrimethoxysilane and γ-methacryloxypropane The volume ratio of base trimethoxysilane is 7:1;

[0033] (b) Adding a catalyst with a concentration of 1.2mol / L to (a), and mixing evenly, wherein the ratio of the silylating agent to the catalyst is 4:1;

[0034] (c) pouring the liquid in (b) into the high performance liquid chromatography stainless steel column, sealing both ends of the mold, and placing it vertically at a temperature of 45° C. for 20 hours;

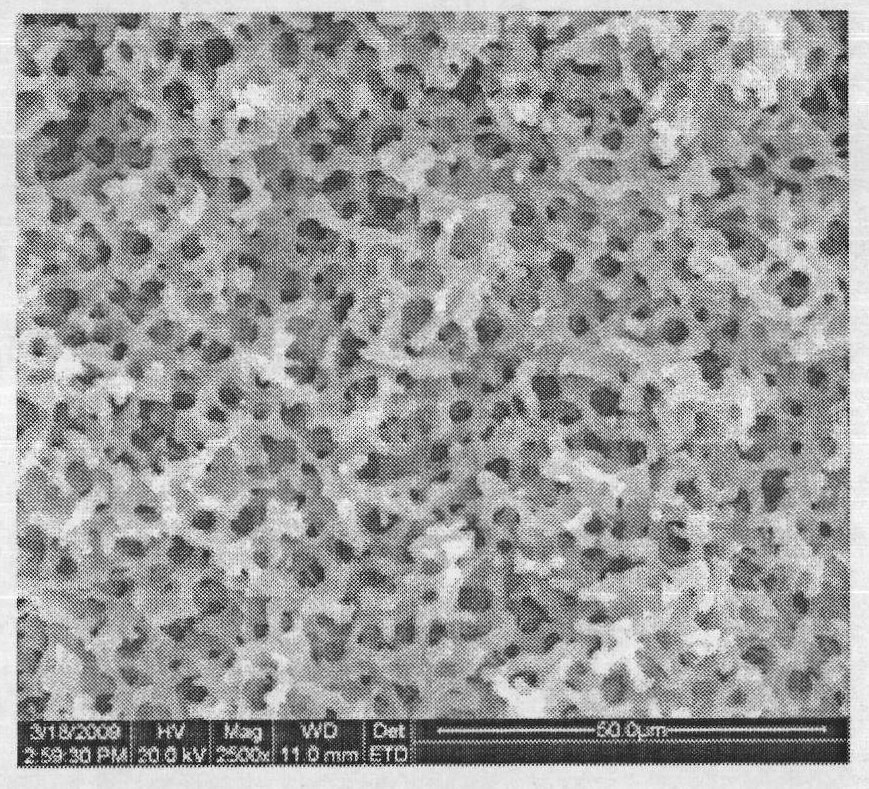

[0035] (d) After the reaction is over, the stainless steel column is connected to the high-performance liquid chromatography system, and the column body is washed with methanol to obtain a silica gel monolithic column skeleton; figure 1 It is a scanning electron micrograph of the cross-section of the...

Embodiment 2

[0044] A western blot material, which can be prepared as follows:

[0045] (a) Add 1.2ml of silylating reagent to ethanol and mix well. The volume ratio of silylating reagent to methanol is 2:1. Two silylating reagents, methyltriethoxysilane and γ-methacryloxy The volume ratio of propyltrimethoxysilane is 9:1;

[0046] (b) Add a catalyst with a concentration of 1.0mol / L to (a), and mix evenly, wherein the ratio of the silylating agent to the catalyst is 4:1;

[0047] (c) pouring the liquid in (b) into the capillary column, sealing both ends of the mold, and placing it vertically at a temperature of 47° C. for 30 hours;

[0048] (d) after the reaction is finished, the column body is washed with methanol to obtain a silica gel monolithic column skeleton;

[0049] (e) Dissolving the functional monomer and the cross-linking agent in the tris-hydrochloric acid (Tris-HCl) buffer solution of pH 7.10 of 10mM, the functional monomer in the buffer solution is NIPAAm (1.0290g), AAm ( ...

Embodiment 3

[0056] A western blot material, which can be prepared as follows:

[0057] (a) Add 1.2ml of silylating reagent to ethanol, mix well, the volume ratio of silylating reagent to methanol is 3:1, the volume of two silylating reagents tetraethoxysilane and aminopropyltrimethoxysilane The ratio is 5:1;

[0058] (b) adding a catalyst with a concentration of 0.8mol / L to (a), and mixing evenly, wherein the ratio of the silylating agent to the catalyst is 4:1;

[0059] (c) pouring the liquid in (b) into the capillary column, sealing both ends of the mold, and placing it vertically at a temperature of 50° C. for 12 hours;

[0060] (d) after the reaction is finished, the column body is washed with methanol to obtain a silica gel monolithic column skeleton;

[0061] (e) Dissolving the functional monomer and the cross-linking agent in the tris-hydrochloric acid (Tris-HCl) buffer solution of pH 7.10 of 10mM, the functional monomer in the buffer solution is NIPAAm (1.0513g), AAm ( 20.0mg) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com