Silver paste printing ink for scratch notes and preparation method thereof

A silver paste ink and scratch-off technology, which is applied in the field of preparation of silver paste ink, can solve the problems of weak hiding power and low gloss of silver paste ink, so as to reduce production cost, improve printing gloss, and change wetting sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

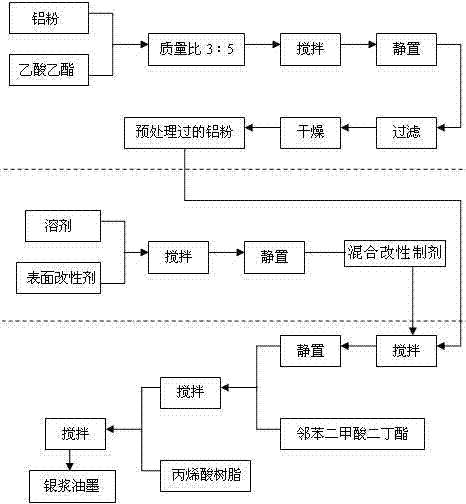

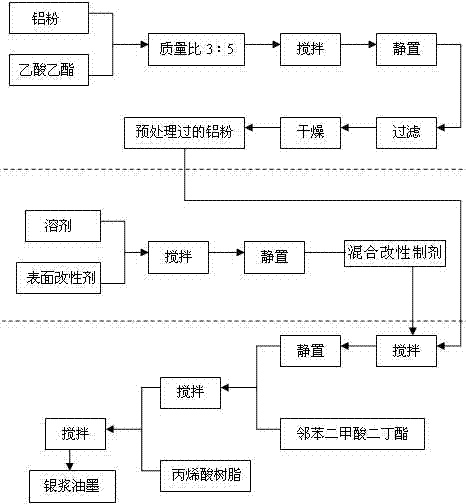

[0022] The preparation method of above-mentioned silver paste ink of the present invention, as figure 1 , follow the steps below to implement:

[0023] Step 1. Weigh each component, the total mass percentage is 100%, of which the aluminum powder is 48.72%-51.22%, the particle size is 11-14μm, the solvent is 24.65%-27.75%, and the surface modifier is 0.49%- 1.02%, dibutyl phthalate is 0.5%-0.6%, acrylic resin is 19.51%-25.64%;

[0024] Step 2. Compare the quality of aluminum powder weighed in step 1, and weigh ethyl acetate according to the ratio of aluminum powder to ethyl acetate mass ratio of 3:5, add the ethyl acetate weighed in this step to step 1 and weigh In the aluminum powder, stir with a magnetic stirrer for 2-3h, filter after standing for 2-3h, and dry at 40-60°C for 2-3h to obtain pretreated aluminum powder;

[0025] Step 3. Put the solvent weighed in step 1 into a beaker, add the surface modifier weighed in step 1, stir with a magnetic stirrer for 20-30 minutes, ...

Embodiment 1

[0029] According to the above-mentioned silver paste ink preparation method, as figure 1 As shown, follow the steps below to implement:

[0030] Step 1. Weigh each component, the total mass percentage is 100%, wherein the aluminum powder particle size is 12 μm, the aluminum powder is 51.22%, the solvent is 27.75%, the surface modifier is 1.02%, dibutyl phthalate 0.5% for acrylic resin and 19.51% for acrylic resin. The surface modifier is composed of 15% oleic acid, 30% sodium dodecylbenzene sulfonate, and 55% sodium stearate; the solvent is 45% ethyl acetate, 25% ethylene glycol Alcohol butyl ether, 30% ethylene glycol composition;

[0031] Step 2. Compare the quality of aluminum powder weighed in step 1, and weigh ethyl acetate according to the ratio of aluminum powder to ethyl acetate mass ratio of 3:5, add the ethyl acetate weighed in this step to step 1 and weigh In the aluminum powder, stir with a magnetic stirrer for 3 hours, filter after standing for 3 hours, and dry...

Embodiment 2

[0036] According to the above-mentioned silver paste ink preparation method, as figure 1 As shown, follow the steps below to implement:

[0037] Step 1. Weigh each component, the total mass percentage is 100%, wherein the aluminum powder particle size is 11 μm, the aluminum powder is 48.72%, the solvent is 24.65%, the surface modifier is 0.49%, dibutyl phthalate 0.5% for acrylic resin and 25.64% for acrylic resin. The surface modifier is composed of 20% oleic acid, 30% sodium dodecylbenzenesulfonate, and 50% sodium stearate; the solvent is composed of 55% ethyl acetate, 20% ethylene glycol Alcohol butyl ether, 25% ethylene glycol composition;

[0038] Step 2. Compare the quality of aluminum powder weighed in step 1, and weigh ethyl acetate according to the ratio of aluminum powder to ethyl acetate mass ratio of 3:5, add the ethyl acetate weighed in this step to step 1 and weigh In the aluminum powder, stir with a magnetic stirrer for 2 hours, filter after standing for 2 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com