Modified liquid crystal sealant composition

A liquid crystal sealant and composition technology, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve the problems affecting the screen printability of liquid crystal sealants, the performance decline of liquid crystal sealants, and the difficulty in controlling the particle size of fillers, etc. problems, to achieve the effect of improving printing gloss, printing continuity and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

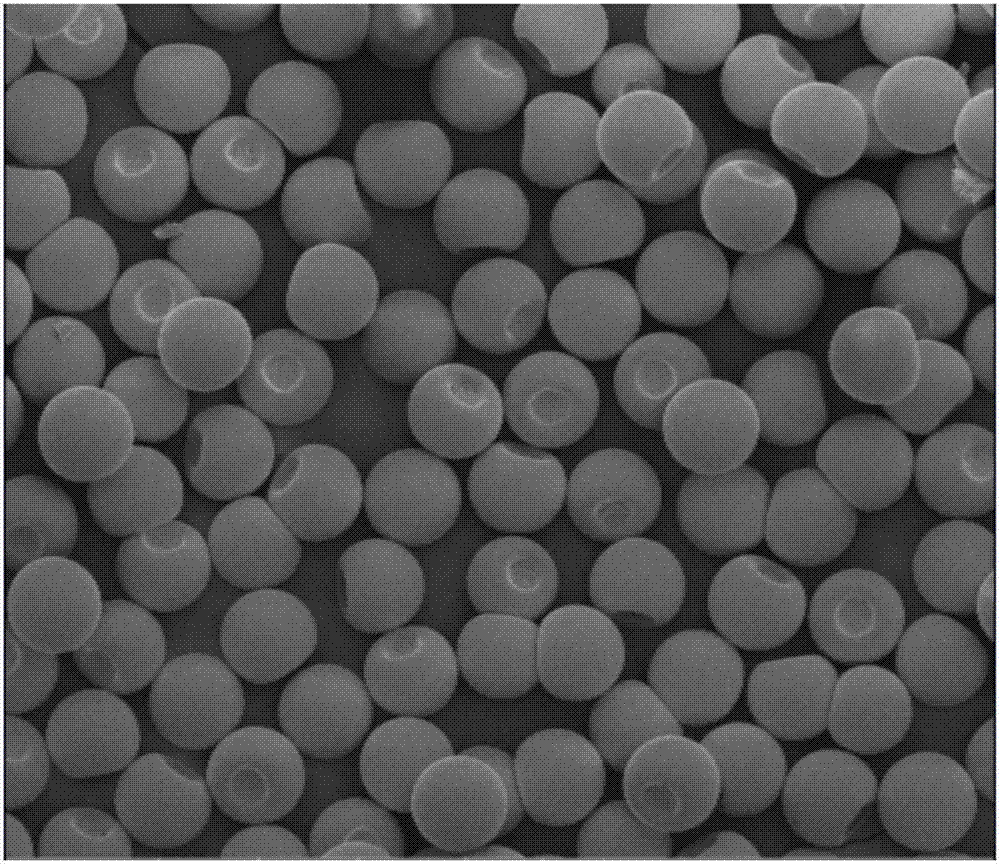

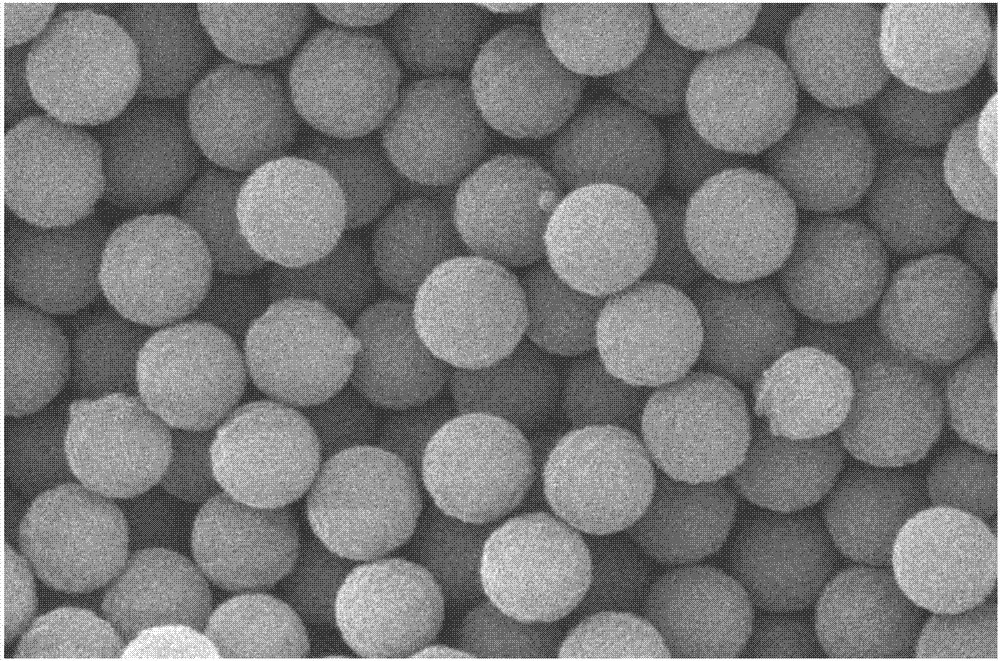

[0028] Preparation of seed microspheres with a particle size of 1 μm: Add 20 g of styrene, 0.2 g of azobisisobutyronitrile, 1 g of polyvinylpyrrolidone, 300 g of absolute ethanol, etc. into a 500 mL three-necked flask, stir until homogeneous, and ventilate with nitrogen gas. Oxygen for 10 minutes, the water bath was heated to 70°C, the rotation speed of the stirring paddle was kept at 60 rpm, and the reaction was carried out for 24 hours. The sample was separated by a high-speed centrifuge, and the lower microspheres were washed with a mixture of ethanol and water for several times. Seed particles with a particle size of about 1 μm can be obtained.

[0029] Preparation of dimple-shaped monodisperse polymer microspheres with a particle size of 2 μm: 50 g of 1 μm seed microspheres, 400 g of monomer (trihydroxypropane trimethacrylate), and 6 L of sodium dodecylbenzenesulfonate aqueous solution The emulsion was added into a three-necked bottle, and stirred and swelled at a constan...

Embodiment 1

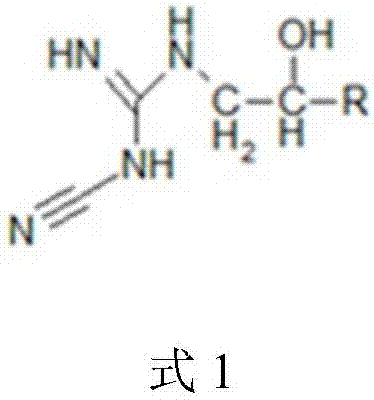

[0032] This example is used to illustrate the liquid crystal sealant composition and its preparation method provided by the present invention.

[0033] raw material:

[0034]

[0035]

[0036] Stir the above-mentioned epoxy resin silane coupling agent and diluent, then add fillers and modified dicyandiamide, stir and disperse, and then grind 3 times on a three-roll mill (Shanghai Shihe Electromechanical Equipment Co., Ltd.) to obtain a liquid crystal sealant combination Object 1.

Embodiment 2

[0038] This example is used to illustrate the liquid crystal sealant composition and its preparation method provided by the present invention.

[0039] raw material:

[0040]

[0041] Stir the above-mentioned epoxy resin silane coupling agent and diluent, then add fillers and modified dicyandiamide, stir and disperse, and then grind 3 times on a three-roll mill (Shanghai Shihe Electromechanical Equipment Co., Ltd.) to obtain a liquid crystal sealant combination Object 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com