Tissue engineered bone cartilage frame and preparation method thereof

A tissue engineering bone and osteochondral technology, applied in the field of tissue engineering osteochondral scaffolds and constructing osteochondral complexes, can solve problems such as interface mechanical defects, poor mechanical properties of upper materials, poor shear resistance, etc., and achieve good flexibility and mechanical properties, reducing antigenicity, and beneficial to osteogenesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 uses fresh bovine femoral condyle as raw material to prepare tissue engineered osteochondral scaffold

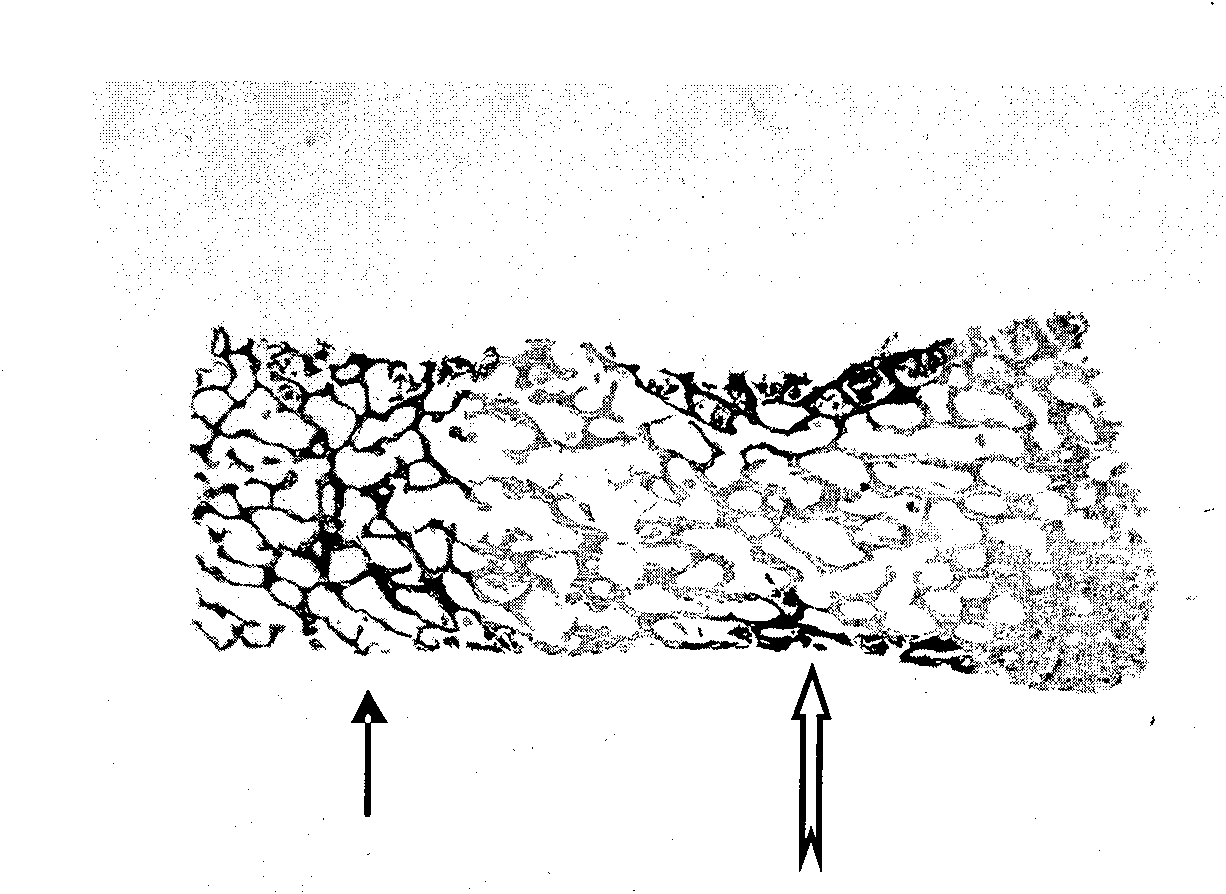

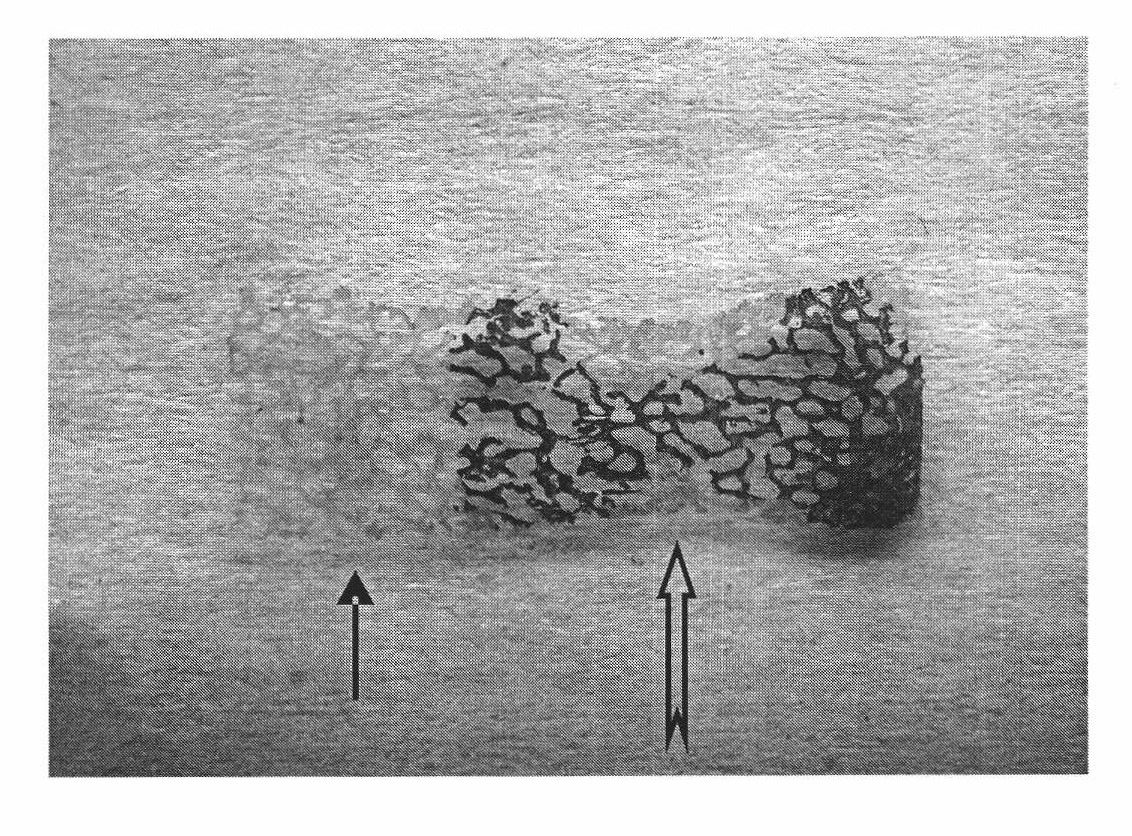

[0036] Purchasing fresh bovine femoral condyles from the market, removing the attached muscles and ligaments, sawing them into 2cm thick bone slices, washing the bone marrow with a high-pressure water gun and triple distilled water, cutting off the bone cortex, and dehydrating with absolute ethanol , degreased with ether, and air-dried. Then, a 4mm diameter trepan was used to make a cancellous bone column with a diameter of 4mm from the treated bovine femoral condyle. The lower 2 / 3 of the cancellous bone column was embedded in paraffin. Place the cancellous bone column as a whole in 10% (w / v) EDTA solution for decalcification for 2 weeks, then remove paraffin with xylene and graded alcohol, soak in PBS buffer solution for more than 1 week, and then use a freeze dryer according to the instructions By freeze-drying, the layered decalcified tissue engineer...

Embodiment 2

[0037] Example 2 Using Fresh Bovine Femoral Condyle as Raw Material to Prepare Tissue Engineering Osteochondral Scaffold

[0038] Purchasing fresh bovine femoral condyles from the market, removing the attached muscles and ligaments, sawing them into 2cm thick bone slices, washing the bone marrow with a high-pressure water gun and triple distilled water, cutting off the bone cortex, and dehydrating with absolute ethanol , degreased with ether, and air-dried. Then a trephine with a diameter of 1 cm was used to make a cancellous bone column with a diameter of 1 cm from the treated bovine femoral condyle. The lower 2 / 3 of the cancellous bone column was embedded in paraffin. The lower 2 / 3 part of the paraffin-embedded cancellous bone column was placed in 10% (w / v) EDTA solution for decalcification for 2 weeks, then the paraffin was removed with xylene and graded alcohol, and soaked in PBS buffer for more than 1 week. Then freeze-dried,.

Embodiment 3

[0039] Example 3 Using Fresh Bovine Femoral Condyle as Raw Material to Prepare Tissue Engineering Osteochondral Scaffold

[0040] Purchasing fresh bovine femoral condyles from the market, removing the attached muscles and ligaments, sawing them into 2cm thick bone slices, washing the bone marrow with a high-pressure water gun and triple distilled water, cutting off the bone cortex, and dehydrating with absolute ethanol , degreased with ether, and air-dried. Then, a 2 cm diameter trepan was used to make a cancellous bone column with a diameter of 2 cm from the treated bovine femoral condyle. The lower 2 / 3 of the cancellous bone column was embedded in paraffin. The lower 2 / 3 part of the paraffin-embedded cancellous bone column was placed in 10% (w / v) EDTA solution for decalcification for 2 weeks, then the paraffin was removed with xylene and graded alcohol, and soaked in PBS buffer for more than 1 week. Then freeze dry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com