Method for treating saccharin wastewater

A treatment method and wastewater technology, which can be used in water/sewage treatment, natural water treatment, flotation water/sewage treatment, etc., and can solve problems such as failure to meet secondary discharge standards and poor effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

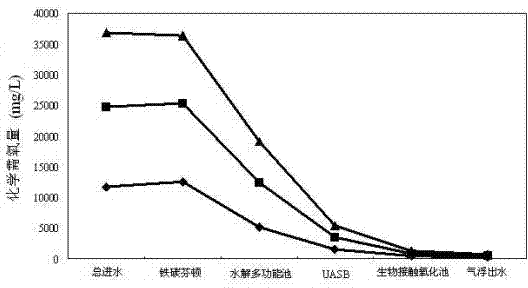

Image

Examples

specific Embodiment approach 1

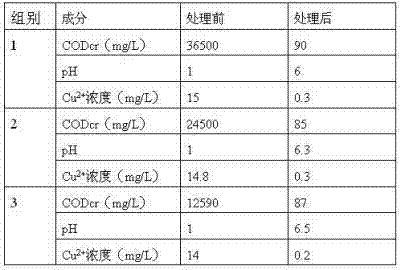

[0007] Embodiment 1: The treatment method of saccharin wastewater according to the present embodiment is carried out according to the following steps: 1. Add saccharin wastewater to a reactor equipped with a mixture of iron filings and activated carbon, and then press wastewater: hydrogen peroxide = 1: 0.1~ Add hydrogen peroxide at a volume ratio of 0.5, and adjust Fe 2+ The concentration is 50mg / L~200mg / L, the pH value is 4~5, and the hydraulic retention time is 2.0h~3.5h; 2. The effluent treated in step 1 flows into the first sedimentation tank for sedimentation treatment; The supernatant obtained after the treatment in step 2 flows into the hydrolysis multifunctional pool, and the concentration of anaerobic activated sludge in the hydrolysis multifunctional pool is 10kg / m 3 ~20kg / m 3 , the dissolved oxygen content is 0.1mg / L~0.3mg / L, the pH value is 4~5, and the hydraulic retention time is 10h~14h; 4. The supernatant obtained after the treatment in step 3 flows into the up...

specific Embodiment approach 2

[0009] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, hydrogen peroxide is added according to the volume ratio of waste water: hydrogen peroxide = 1:0.2~0.4, and the Fe 2+ The concentration is 60mg / L~180mg / L, the pH value is 4.2~4.8, and the hydraulic retention time is 2.2h~3.3h. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: in step one, add hydrogen peroxide according to the volume ratio of waste water: hydrogen peroxide = 1:0.3, and adjust Fe 2+ The concentration is 100mg / L, the pH value is 4.5, and the hydraulic retention time is 2.8h. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com