Adhesive for automobile disc brake pad and preparation method thereof

A technology of disc brake pads and adhesives, which is applied in the direction of adhesives, adhesive types, conjugated diene adhesives, etc., and can solve problems such as not being able to be stored for a long time, compatibility is not very ideal, and the adhesive system is unstable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

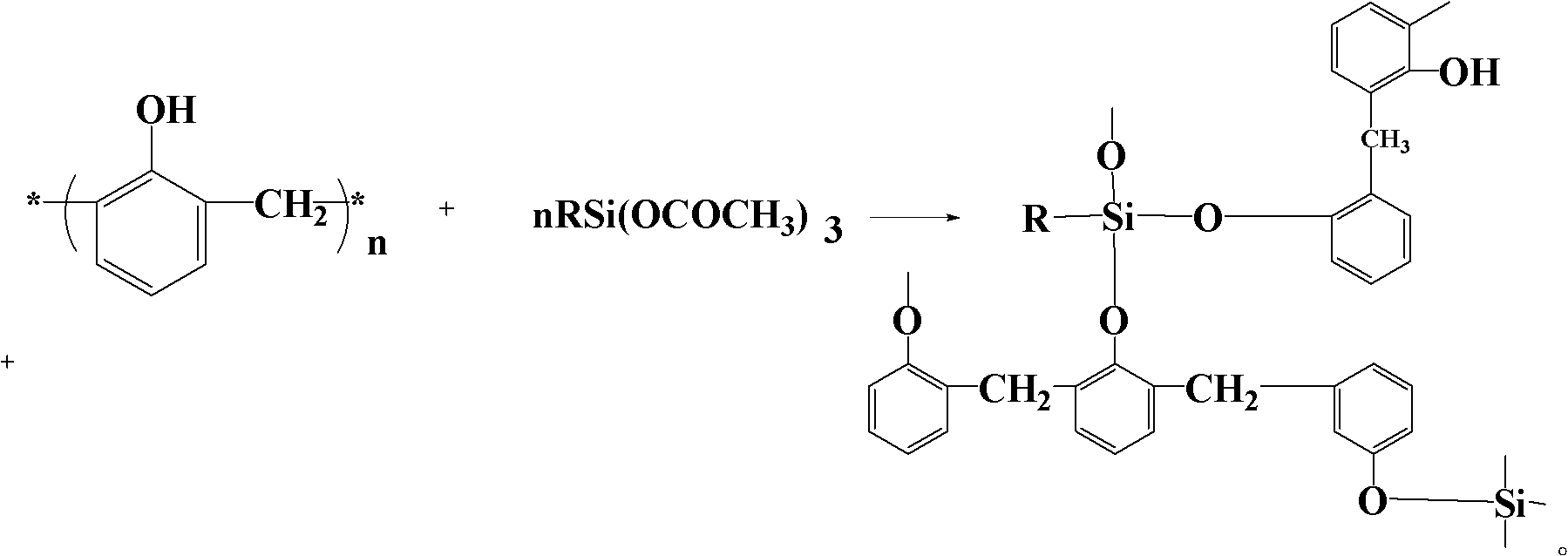

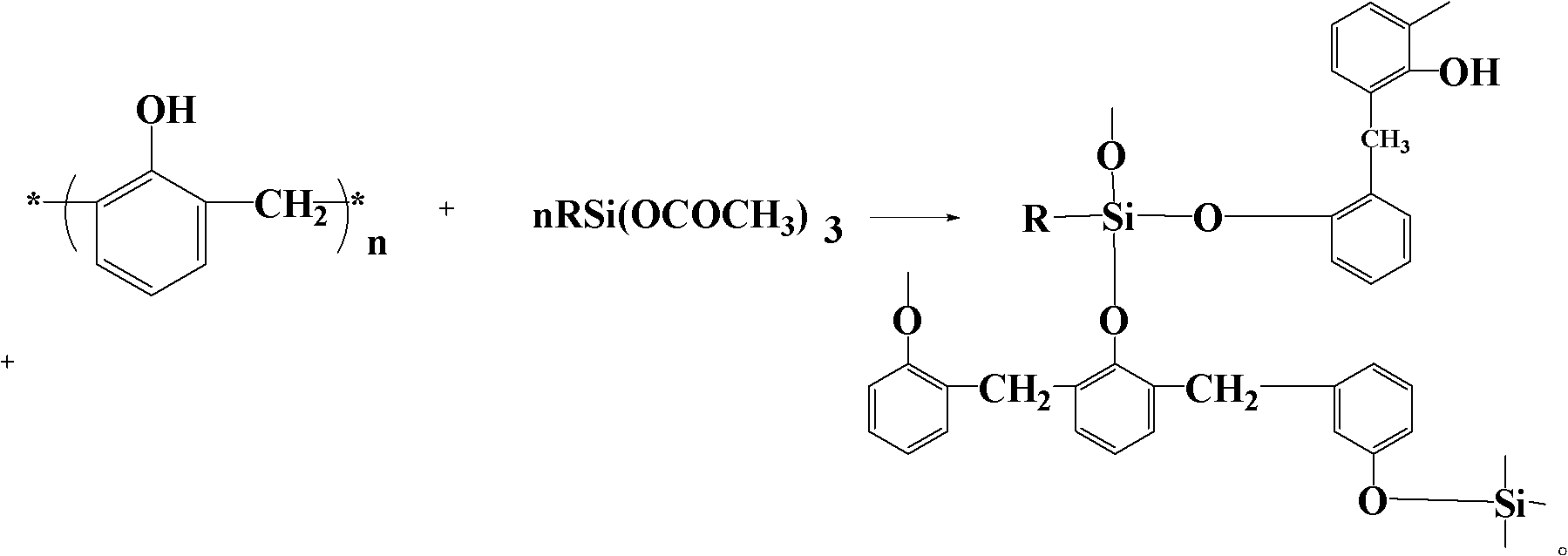

Method used

Image

Examples

Embodiment 1

[0020] 100kg of phenol and 140kg of aqueous formaldehyde were added to the reactor, and 30kg of ammonia was added. At 100°C, after 2 hours of reaction, after adding 60kg of organic organic acetoxysilane, the reaction was continued for 4 hours at 100°C, and cooled to 60°C. , dehydration under the condition of vacuum degree of 700-750mmHg, and the reaction ends when the viscosity is measured in No. 4 paint cup at 20-40s / 60°C. Then add 500g of solvent per kilogram of phenolic resin under the condition of 80°C, and finally add 30kg of nitrile rubber. 10kg of propyl gallate, stir evenly to obtain an adhesive for brake pads. Wherein the solvent is one or a combination of ethanol, acetone, ethyl acetate, butyl acetate, ethyl ketone and the like.

Embodiment 2

[0022] 94kg of phenol, 10kg of sodium hydroxide aqueous solution (0.1mol / L). Make it fully dissolved. Add an appropriate amount of paraformaldehyde 120kg, and the mixture is heated to 80 ~ 100 ° C, after 2 hours of constant temperature reaction, after adding 50 kg of organic organoacetoxysilane, continue to react at 100 ° C for 4 hours, and cool down to 60 ℃, dehydrate under the condition of vacuum degree of 700-750mmHg, and measure the viscosity in No. 4 paint cup when the reaction ends at 20-40s / 60℃. Then add the solvent of 500g per kilogram of phenolic resin under the condition of 80°C, and finally add 30kg of nitrile rubber and 10kg of propyl gallate, stir evenly, and obtain the adhesive for brake pads. Wherein the solvent should be one or a combination of ethanol, acetone, ethyl acetate, butyl acetate, ethyl ketone and the like.

Embodiment 3

[0024] The difference between this embodiment and the first embodiment is that the added toughening material is polyvinyl butyral, and the rest are the same as those of the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com