Batch type feed-batch fermentation method for streptomyces roseosporus to produce Daptomycin efficiently

A technology of Streptomyces roseospora and daptomycin, which is applied in the field of fed-batch fed-batch fermentation for efficient production of daptomycin by Streptomyces roseospora, which can solve the problem of low daptomycin yield, no fermentation optimization, and production High cost and other issues, to achieve good industrial application and promotion value, easy control of the fermentation process, and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

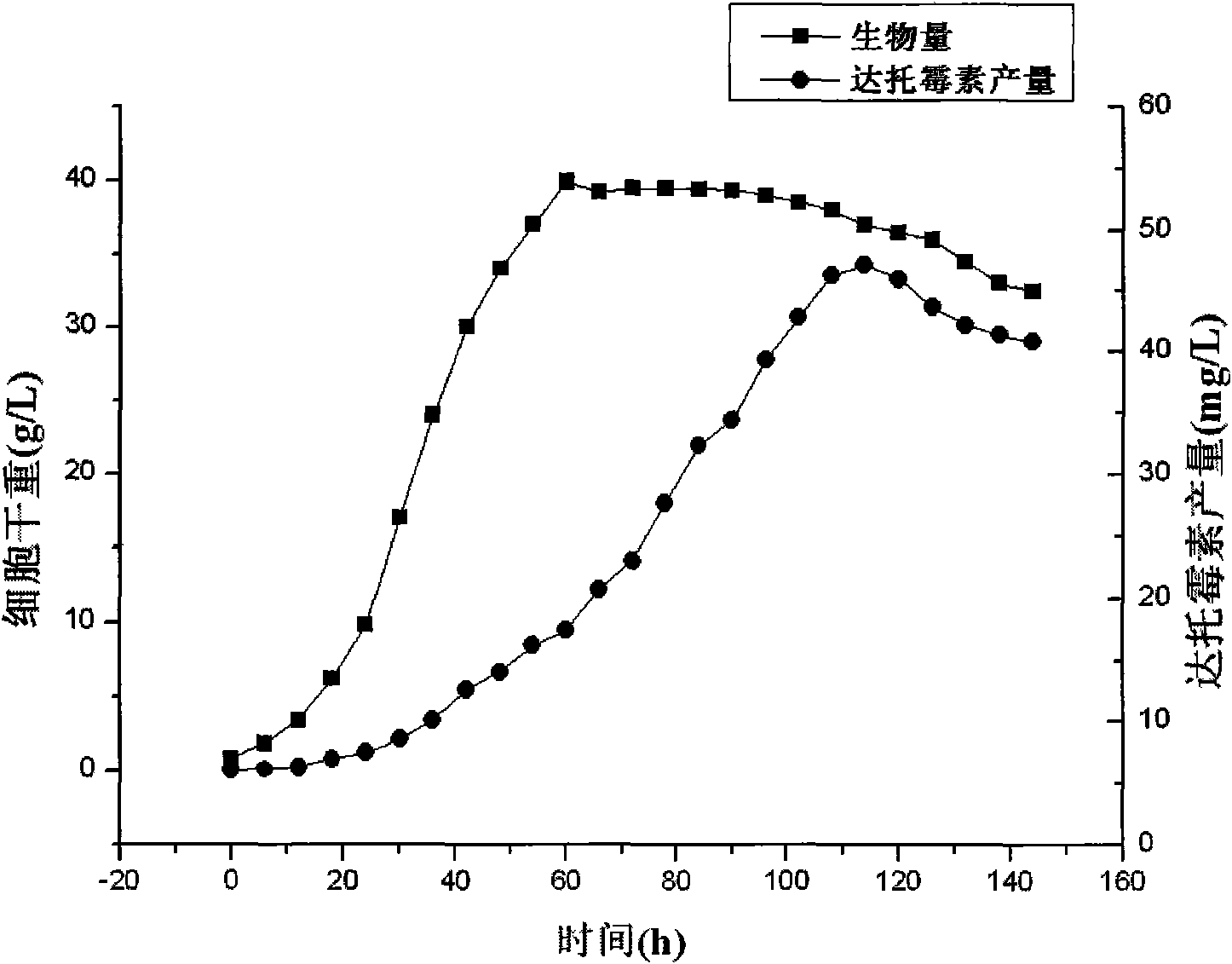

Embodiment 1

[0023] Take spores of Streptomyces reseosporus at room temperature and make spore suspension with sterile water. Then get 0.5 milliliter of spore suspension and inoculate in 250 milliliter shake flasks that 30 milliliters of seed culture medium are housed, 30 ℃, in 180~220rpm shaker, cultivate 48 hours. Then inoculate into 7.5L automatic fermenter with 1% inoculum amount. Among them, the fermentation medium components (glucose 1.0g / L, dextrin 3g / L, casein 1.0g / L, peanut cake powder 0.6g / L, L-asparagine 0.12g / L, K 2 SO 4 0.6g / L, initial pH7.0. ) and then fermented for 144 hours at 30°C with the ventilation rate controlled at 0.8v / v / m. The daptomycin concentration in the fermentation broth was monitored by HPLC. Daptomycin fermentation unit increased to 41±0.6mg / L; if figure 1 shown.

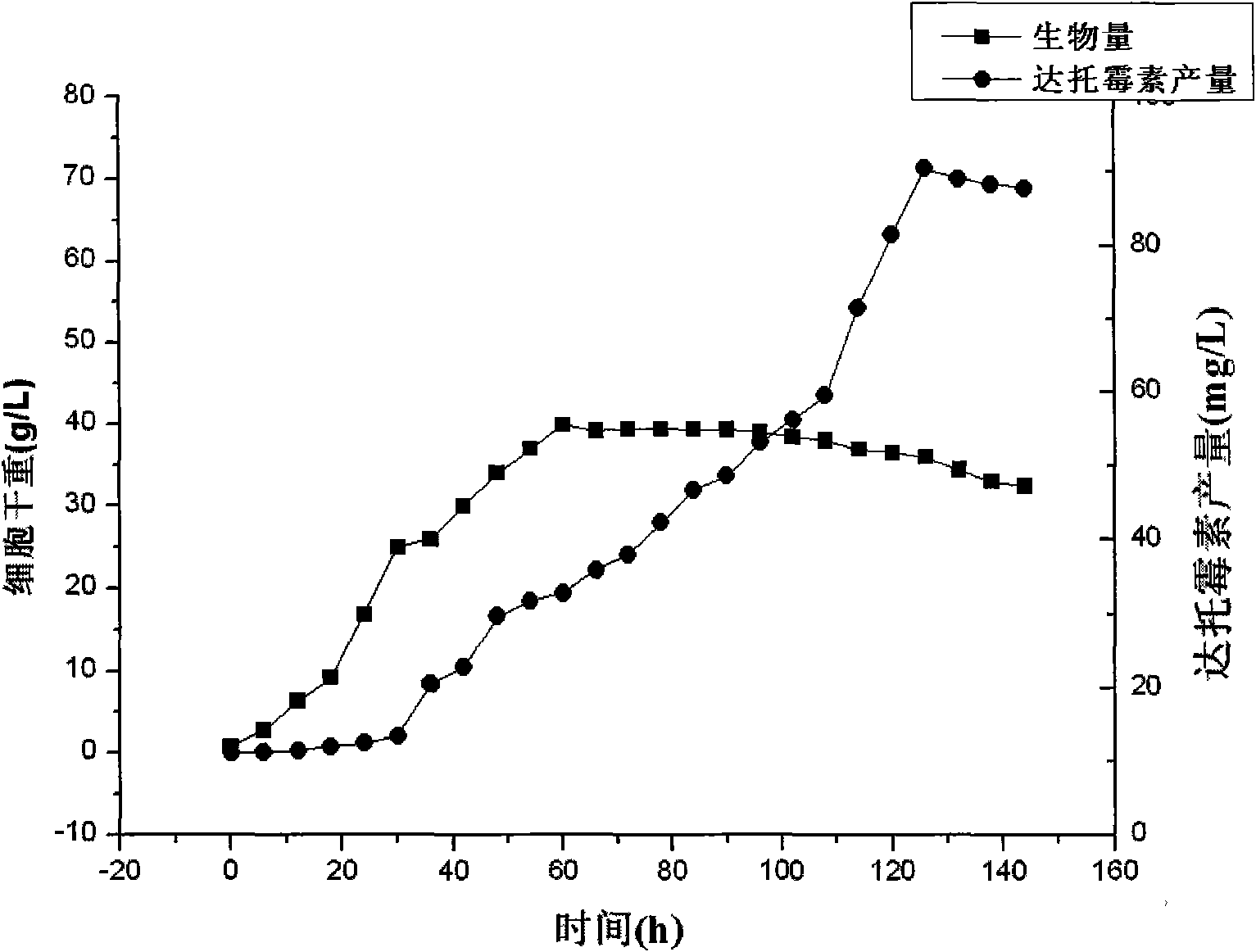

Embodiment 2

[0025] Take spores of Streptomyces reseosporus at room temperature and make spore suspension with sterile water. Then get 0.5 milliliter of spore suspension and inoculate in 250 milliliter shake flasks that 30 milliliters of seed culture medium are housed, 30 ℃, in 180~220rpm shaker, cultivate 48 hours. Then inoculate into 7.5L automatic fermenter with 4% inoculum amount. Among them, the fermentation medium components (glucose 1.0g / L, dextrin 3g / L, casein 1.0g / L, peanut cake powder 0.6g / L, L-asparagine 0.12g / L, K 2 SO 4 0.6g / L, initial pH7.0. ) Then, at 32°C, at 0-30h, the pH is controlled at 6.5, and the dissolved oxygen is 45%; at 30h-144h, the pH is controlled at 7.0, the ventilation rate is controlled at 0.8v / v / m, and fermentation is carried out for 144 hours. The daptomycin concentration in the fermentation broth was monitored by HPLC. The fermentation unit of daptomycin is 85 ± 0.8mg / L, and the output ratio of Example 1 has been improved by 2 times. figure 2 shown...

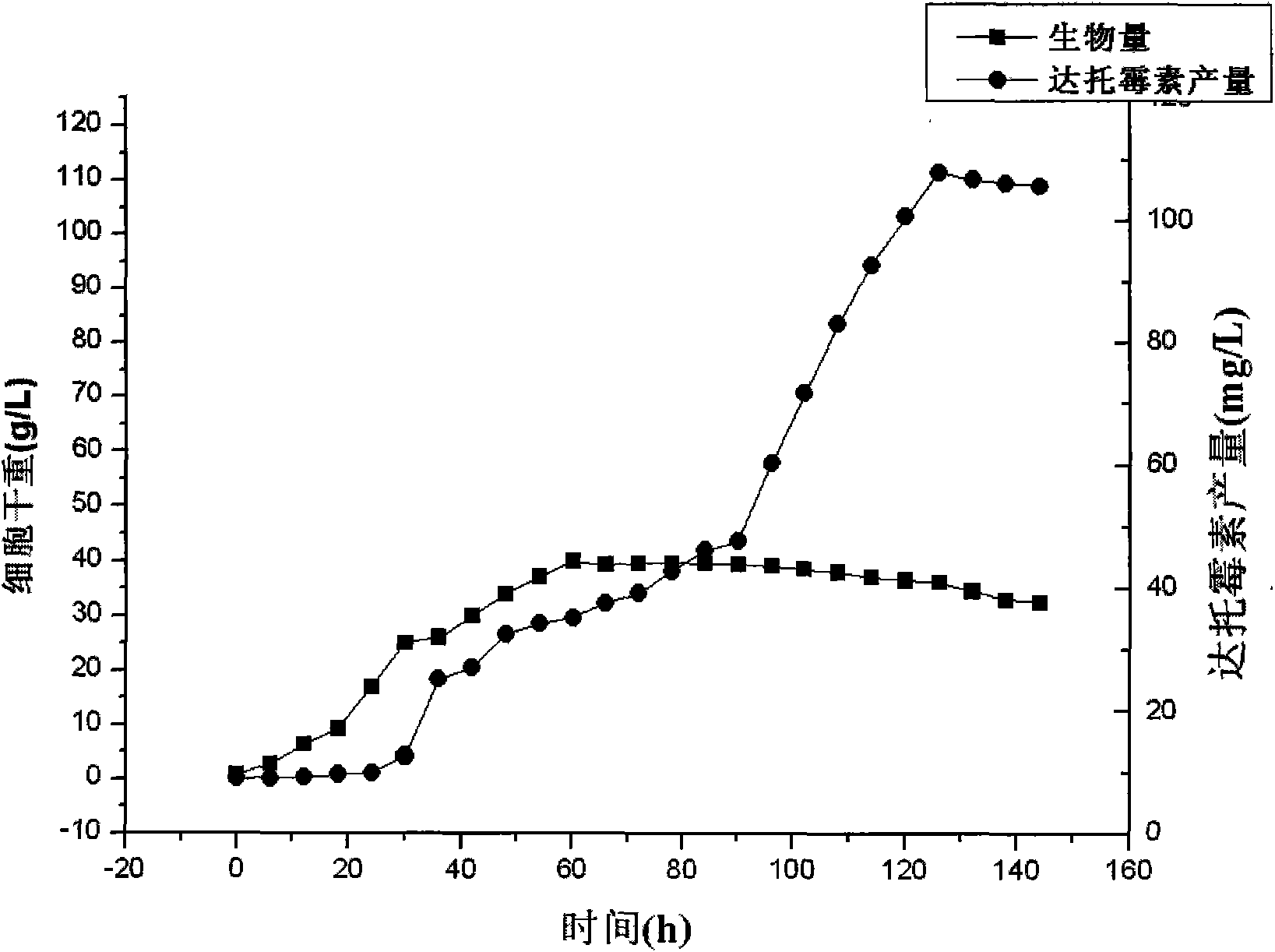

Embodiment 3

[0027] Take spores of Streptomyces reseosporus at room temperature and make spore suspension with sterile water. Then get 0.5 milliliter of spore suspension and inoculate in 250 milliliter shake flasks that 30 milliliters of seed culture medium are housed, 30 ℃, in 180~220rpm shaker, cultivate 48 hours. Then inoculate into 7.5L automatic fermenter with 3% inoculum amount. Among them, the fermentation medium components (glucose 1.0g / L, dextrin 3g / L, casein 1.0g / L, peanut cake powder 0.6g / L, L-asparagine 0.12g / L, K 2 SO 4 0.6g / L, initial pH7.0. ) and then, at 28°C, at 0-30h, control pH6.5, dissolved oxygen 45%,; 30h-144h, control pH7.0, ventilation volume control 0.8v / v / m, 30h at a speed of 0.10mL / h Start feeding 1:1 capric acid and methyl oleate solution to ferment for 144 hours. The daptomycin concentration in the fermentation broth was monitored by HPLC. The daptomycin fermentation unit is 110 ± 0.8mg / L ratio and has improved to embodiment 1 output and improved 2.68 tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com