Soy protein oligopeptide, and preparation method and use thereof

A soybean protein and oligopeptide technology, applied in the field of enzyme catalysis, can solve the problems of tastelessness, low efficiency and low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

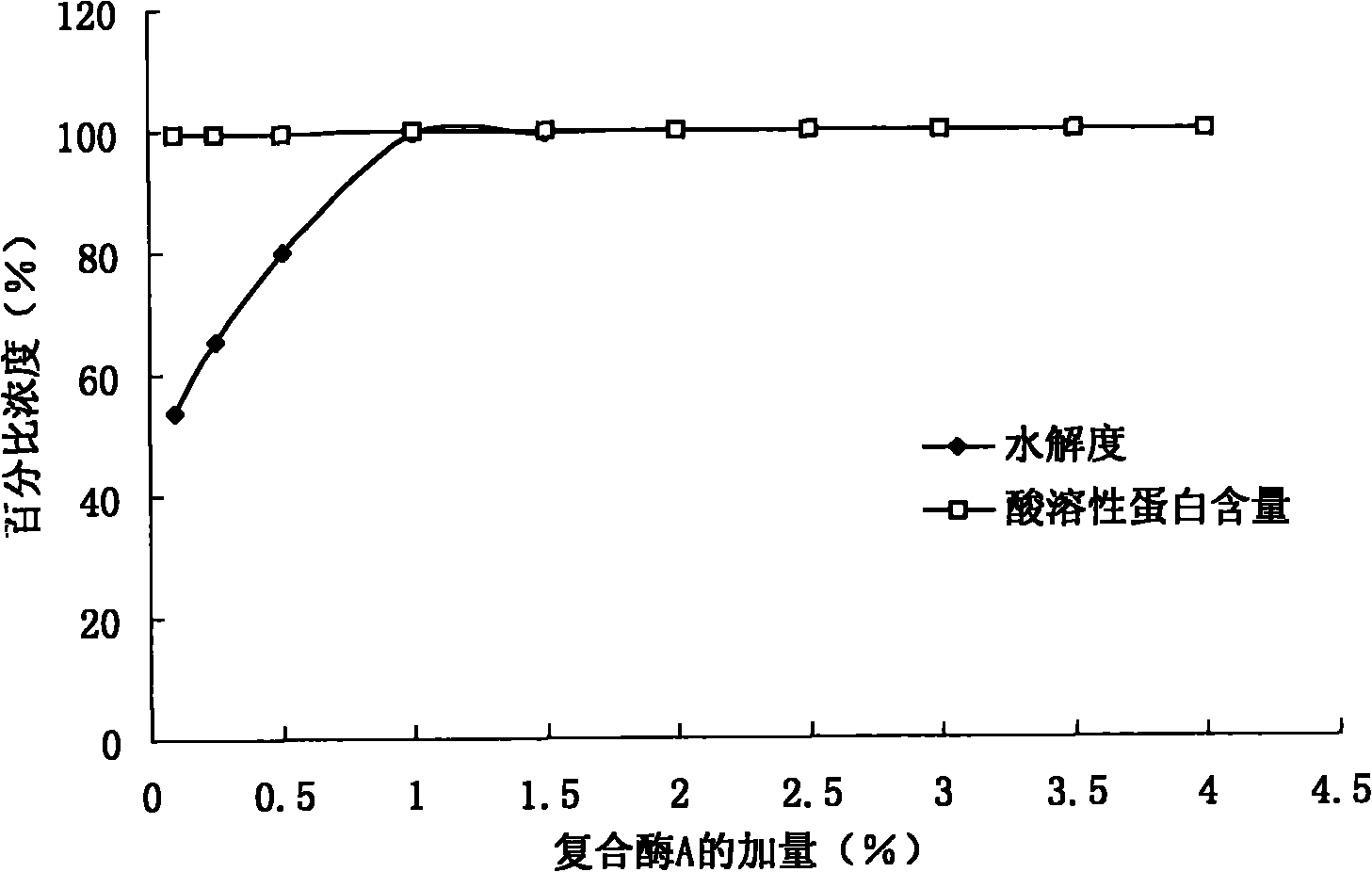

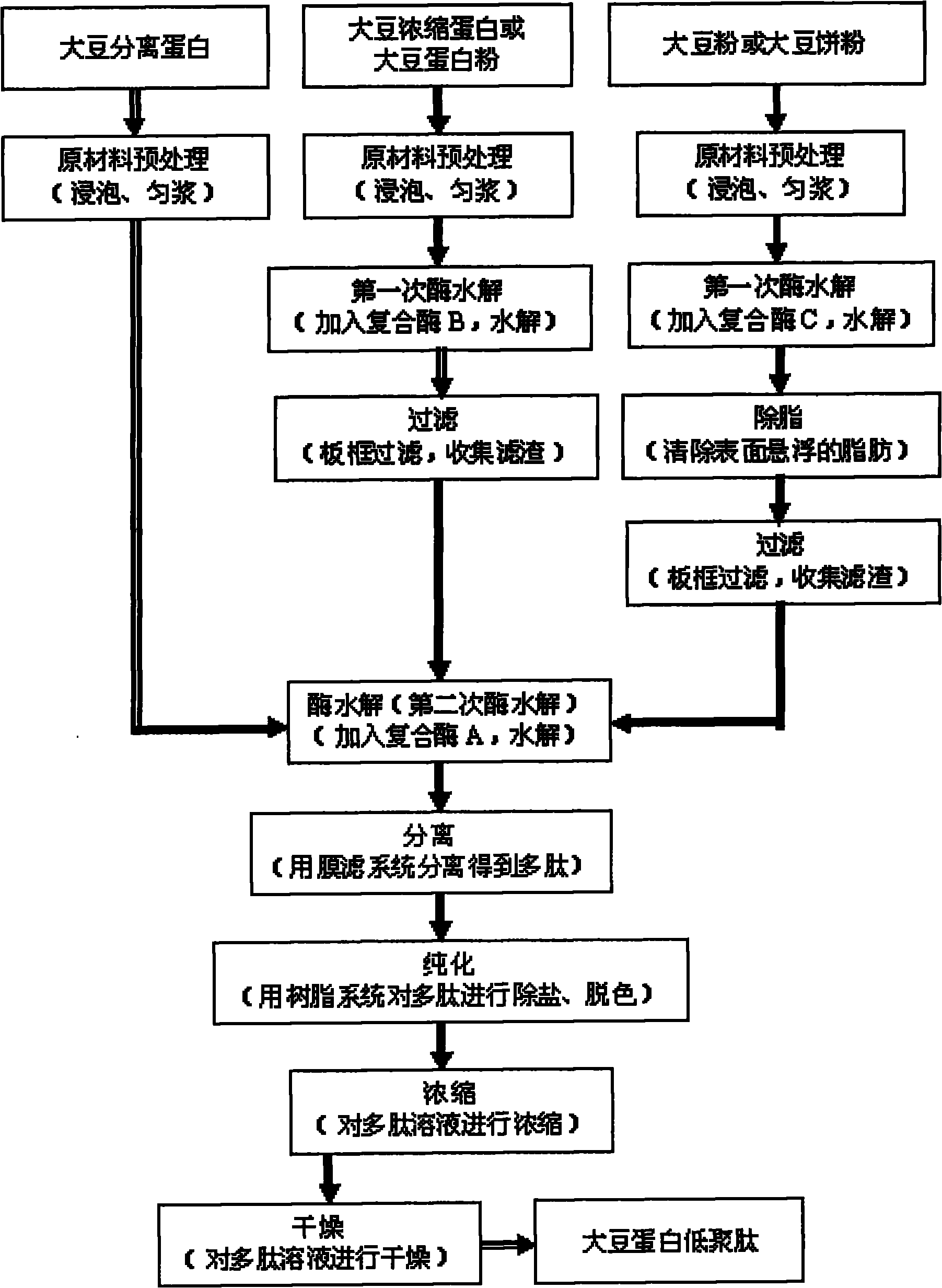

[0072] The invention provides a preparation method of soybean protein oligopeptide, which comprises the steps of: adding compound enzyme A to hydrolyze the raw material after being processed, and passing the hydrolyzed product through microfiltration, desalting and decolorizing through D315 and 335 resin, and finally making soybean protein oligopeptides.

[0073] In a preferred embodiment of the present invention, based on the total weight of solids, the compound enzyme A is added in an amount of 1-3w / w% of the solids content.

[0074] In a preferred embodiment of the present invention, the hydrolysis is carried out at 55°C-65°C and pH 8-9 for 8-12 hours; more preferably, it is then kept at 75-85°C for 30 minutes.

[0075] In another preferred embodiment of the present invention, the raw material of the method for preparing soybean protein oligopeptides is soybean protein isolate, comprising the following steps:

[0076] 1) Raw material pretreatment: mix soybean protein isola...

Embodiment 1

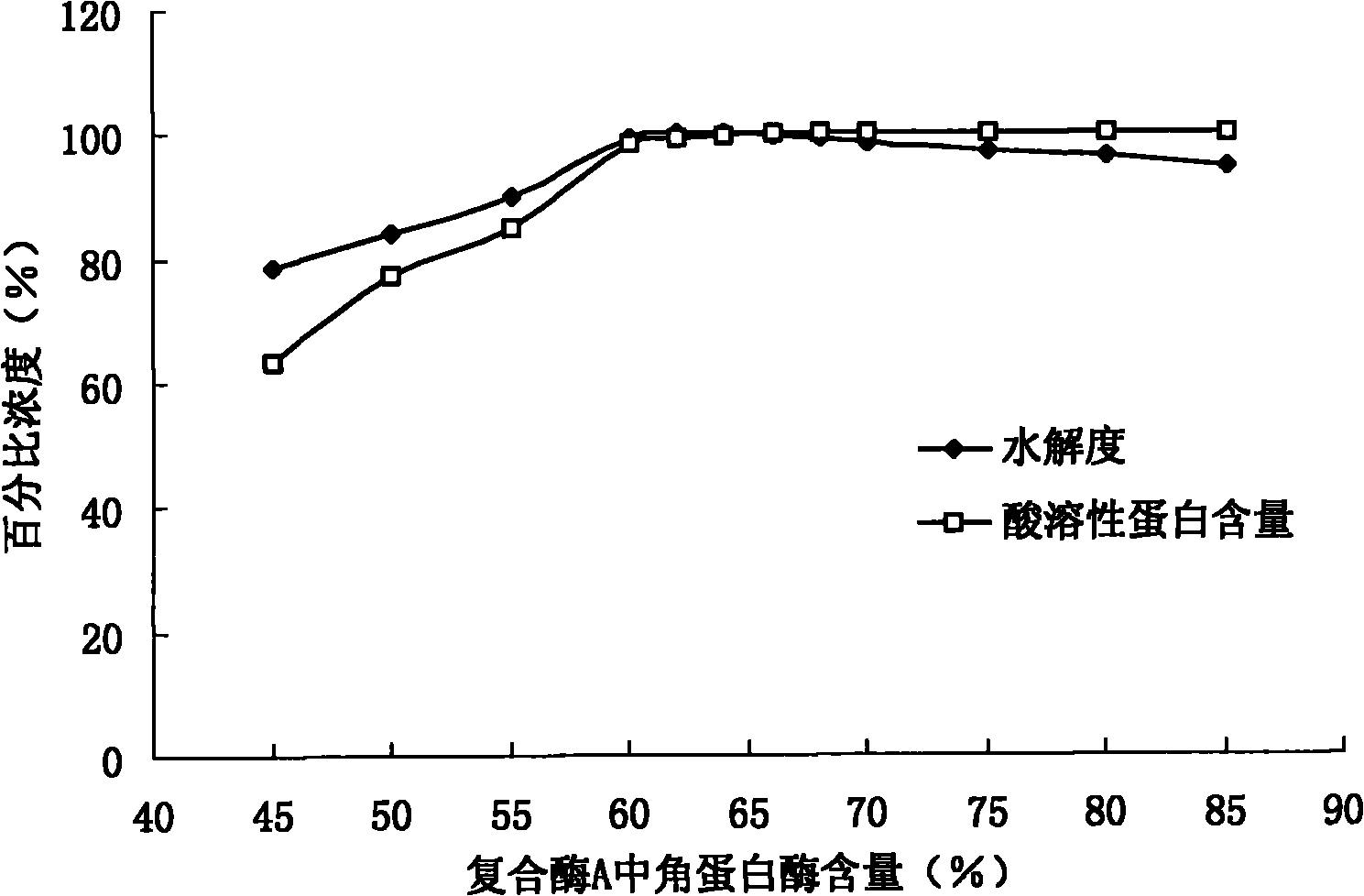

[0119] Hydrolysis of soybean protein by compound enzyme A

[0120] In the range of 45-85w / w%, gradually adjust the percentage concentration of keratinase in the compound enzyme A, then according to step 1) to step 2) described in Example 2 (1), or Example 2 (2) Step 1) to step 4) described in, or step 1) to step 5) described in embodiment 2 (3) implements compound enzyme A to the hydrolysis of soybean protein (the amount of compound enzyme A is according to 2w of raw material amount / w% added), after hydrolysis finishes, get enzymolysis solution 5ml12000rpm centrifugal 5 minutes, get supernatant and measure soluble protein content with Folin-phenol method, and calculate degree of hydrolysis DH according to following formula:

[0121] DH ( % ) = ( N 2 - N 1 ...

Embodiment 2

[0133] Preparation of soybean protein oligopeptide

[0134] (1) Using soybean protein isolate as raw material

[0135] Using soybean protein isolate as raw material, the preparation of soybean protein oligopeptides is carried out according to the following steps, and the process flow is as follows: image 3 shown.

[0136] 1) Pretreatment of raw materials: mix soybean protein isolate with water (m / v) according to the solid-to-liquid ratio of 1:3-1:9, adjust the pH to 5-6, raise the temperature to 30°C-40°C, and Conditional insulation for 30 minutes, then the mixed solution is ground into an emulsion through a colloid mill;

[0137] 2) Enzymatic hydrolysis: Add the emulsion into the reaction tank, adjust the pH to 8-9, raise the temperature to 55°C-65°C, add compound enzyme A (m / m) according to 1%-3% of the solid content, and mix After uniformity, hydrolyze under this condition for 8-12 hours, then rapidly raise the temperature to 75°C-85°C, and keep it warm for 30 minutes; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com