Calcium titanate photocatalyst for removing arsenic by photocatalysis

A technology of photocatalyst and calcium titanate, which is applied in the field of photocatalysis, can solve the problems of high cost and secondary pollution of water bodies, and achieve the effect of avoiding secondary pollution, simple and easy preparation method, and conducive to large-scale promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

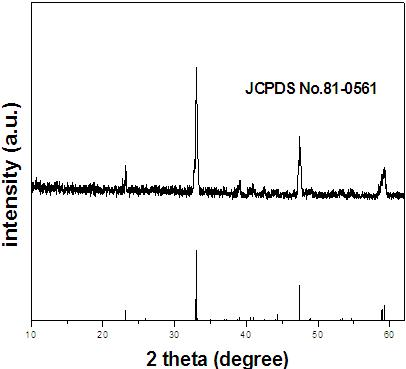

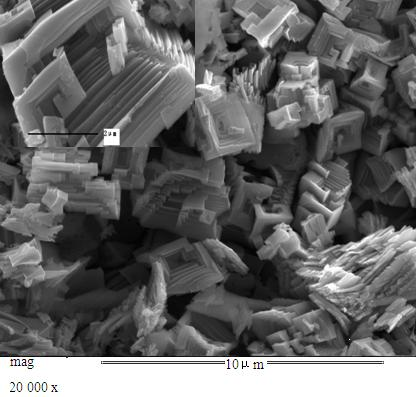

[0023] (1) Preparation of calcium titanate with layered microstructure (TiO(OH) 2 Molar ratio with calcium nitrate is 1:1)

[0024] Dissolve (0.0221mol) n-tetrabutyl titanate in 250mL KOH solution, add deionized water to dilute to 300mL, at this time the concentration of n-tetrabutyl titanate is 0.077mol / L, and the molar ratio of n-tetrabutyl titanate to KOH is 1 : 3.0, stirred for 30 minutes to obtain a mixed solution; then the mixed solution was heated to boiling to completely hydrolyze n-tetrabutyl titanate to obtain TiO(OH) 2 The suspension was centrifuged and washed to obtain 0.0221mol of TiO(OH) 2 . In addition, add 0.0221mol calcium nitrate tetrahydrate solid to 50ml deionized water to be mixed with 0.442mol / L calcium nitrate solution, and then prepare the TiO(OH) 2 Mix with calcium nitrate solution and transfer to high-pressure hydrothermal kettle, TiO(OH) 2 The molar ratio to calcium nitrate is 1:1; slowly drop in 0.4mol / L KOH solution, adjust the pH to above 12,...

Embodiment 2

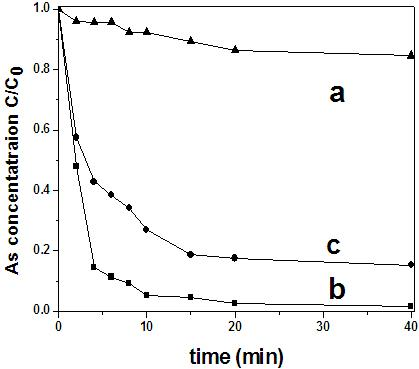

[0030] Photocatalyst CaTiO 3 Application of treatment of arsenic polluted water body:

[0031] The CaTiO that embodiment 1 obtains 3 Powder (TiO(OH) 2 Molar ratio of 1:1 with calcium nitrate) was used as photocatalyst to degrade As(III). Weighed 80mg sample and added it into 80mL As(III) solution (2mg / L), stirred magnetically, and then turned on the light source for photocatalytic reaction. Take 2mL reaction solution at regular intervals, after centrifugation, divide into two parts, dilute with 2~3% HCL respectively, record as As(III); dilute with hydrochloric acid solution containing 1% thiourea and ascorbic acid (dilute As(Ⅴ) generated by oxidation is re-reduced to As(Ⅲ)) and recorded as total arsenic. The concentrations of As(Ⅲ) and total arsenic were detected by PF6 non-scattering atomic fluorescence spectrophotometry. The degradation of As(Ⅲ) is as follows image 3 As shown, it can be seen from the figure that in the pure photocatalyst CaTiO 3 In the presence of As(...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com